Operations Quality Control Checklist for Manufacturing

The Operations Quality Control Checklist for Manufacturing serves as a comprehensive guide to ensure that manufacturing processes adhere to stringent quality standards from inception to completion. Quality control is vital in maintaining product integrity, customer satisfaction, and regulatory compliance.

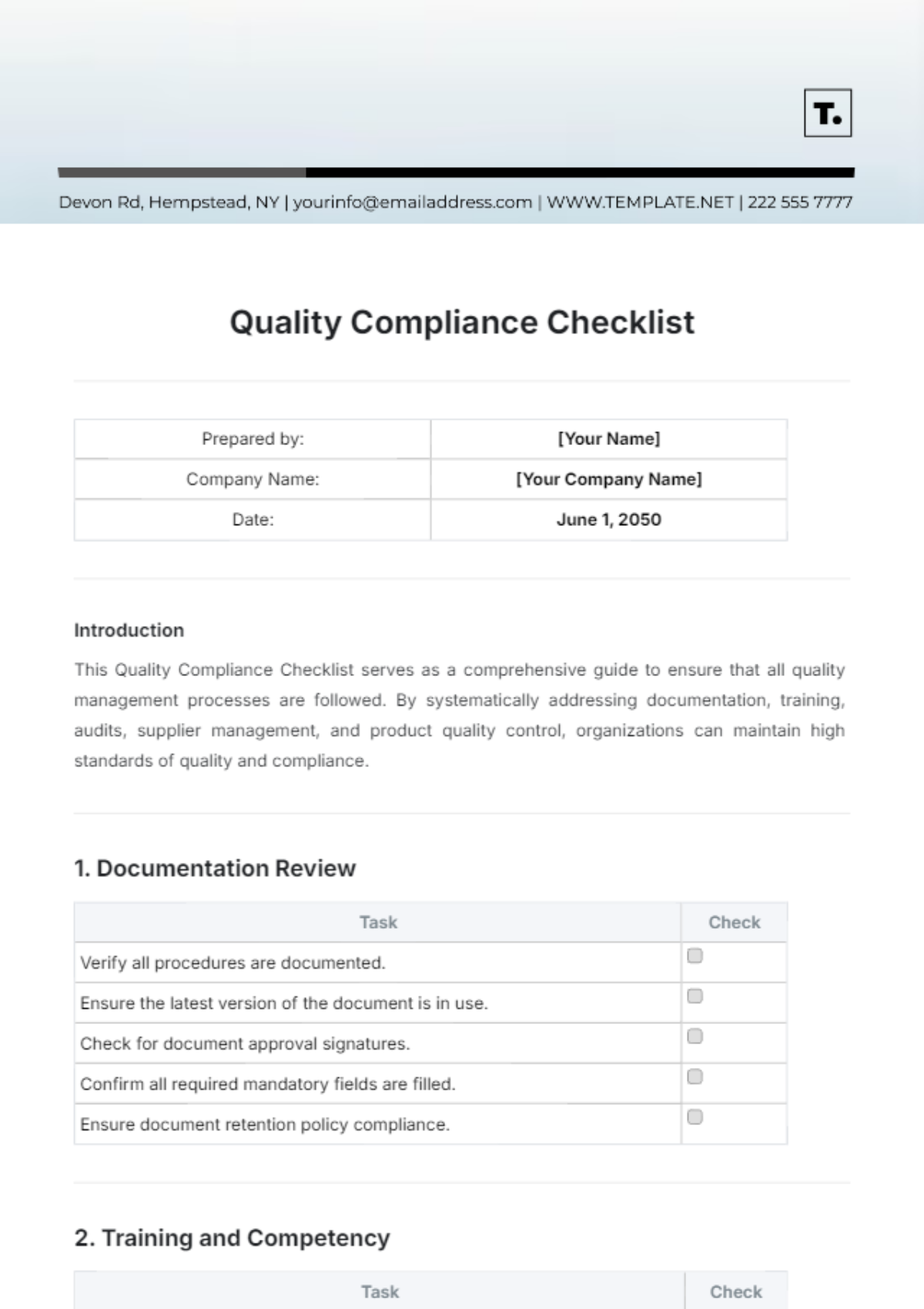

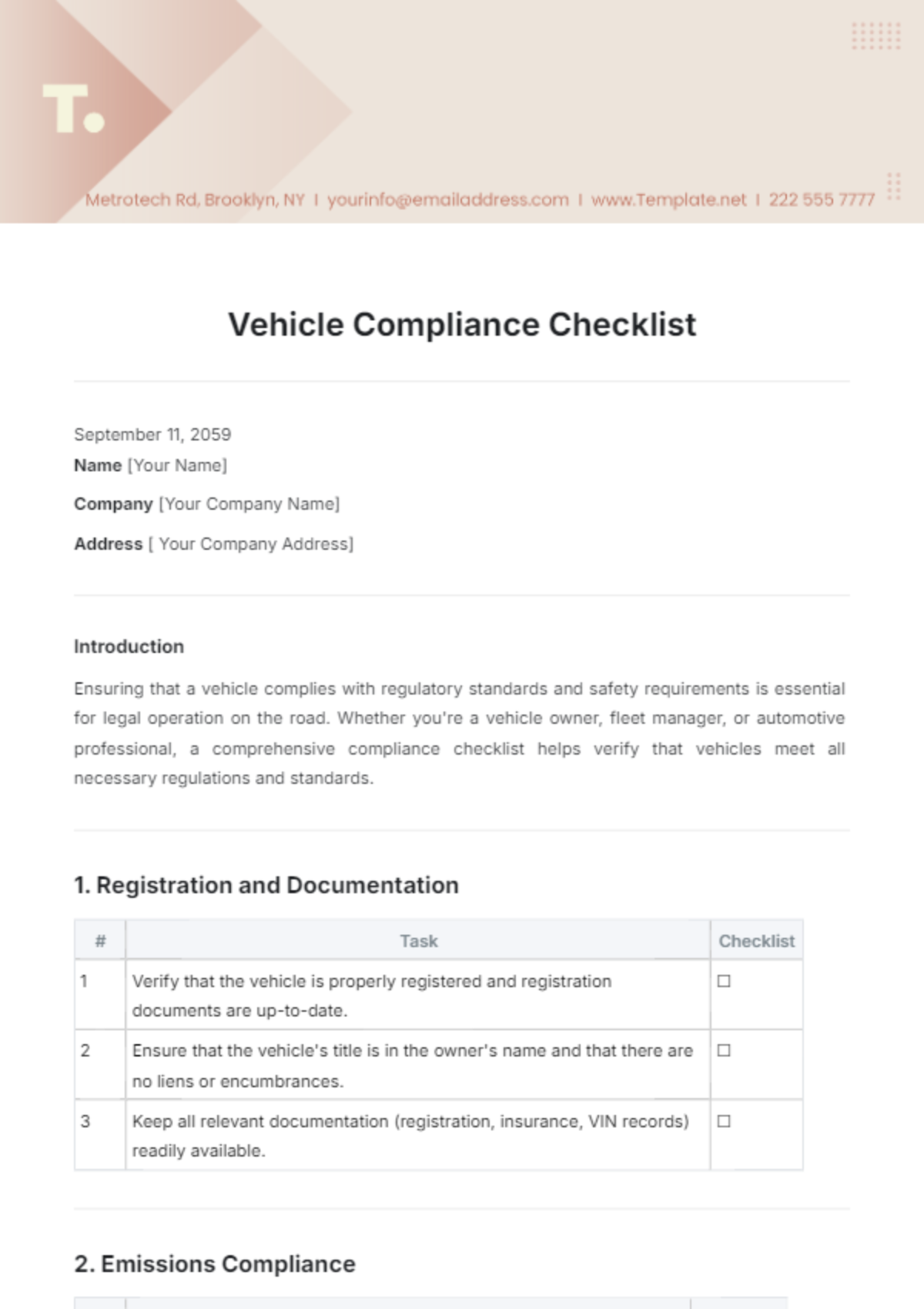

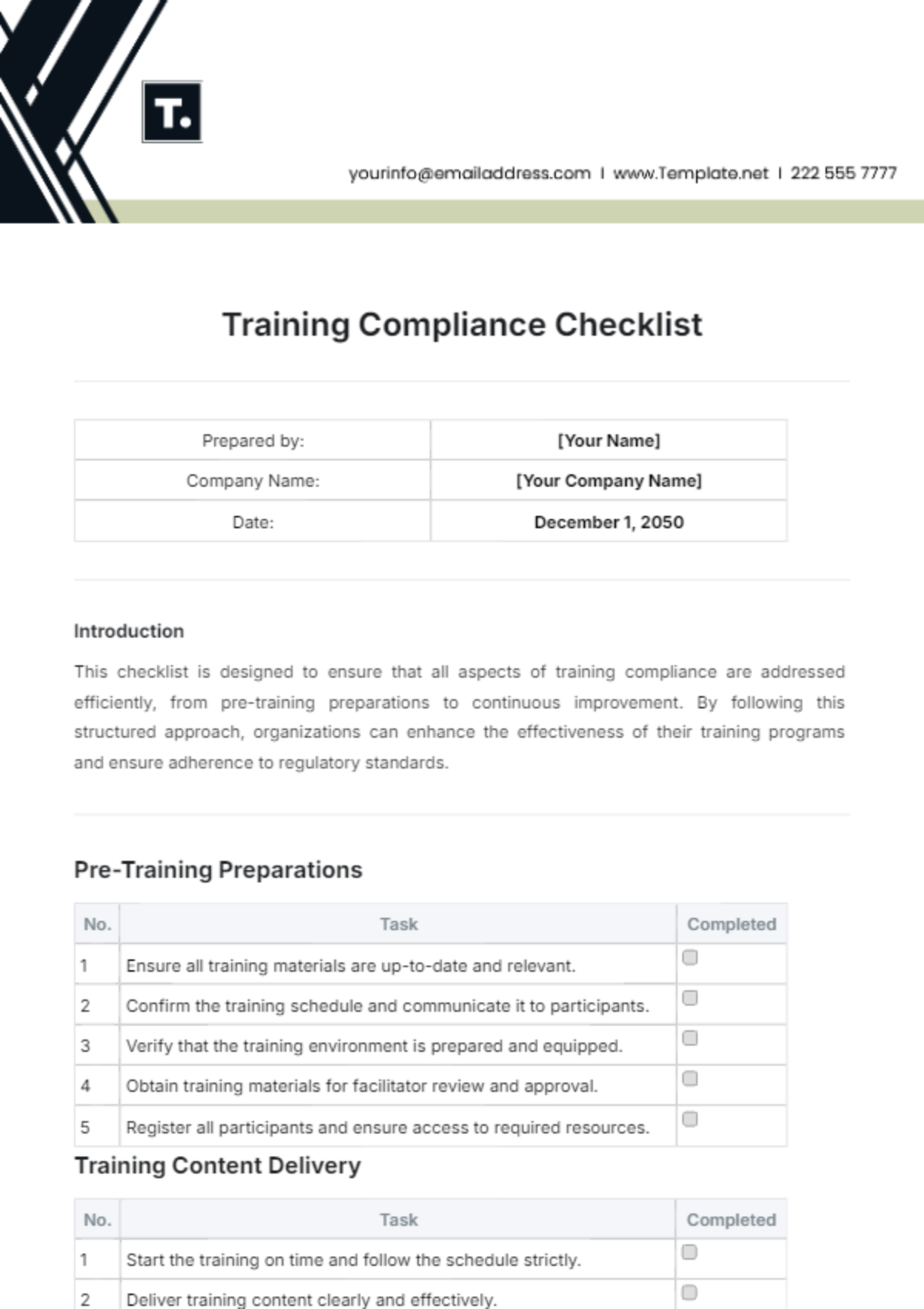

Pre-production Phase

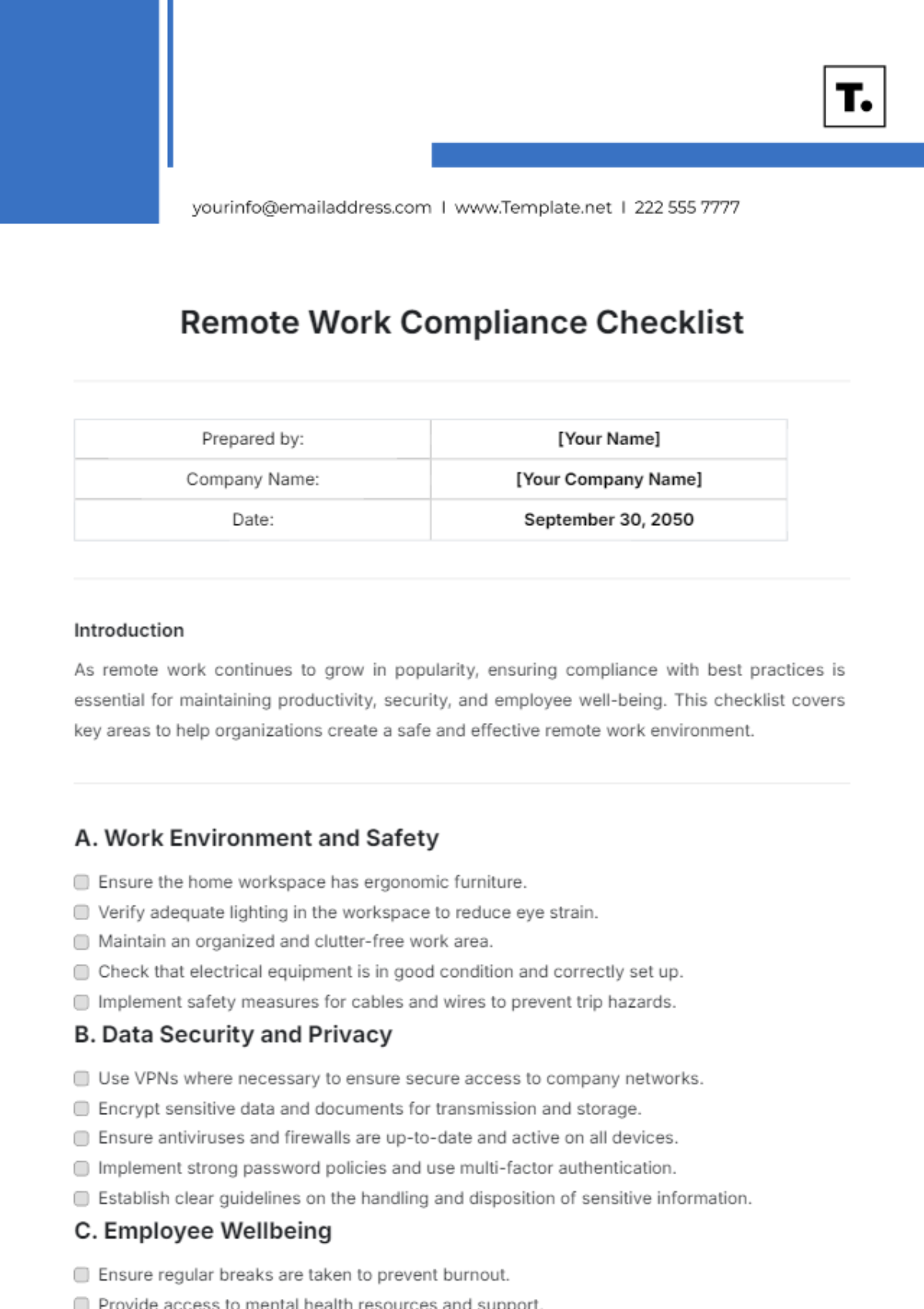

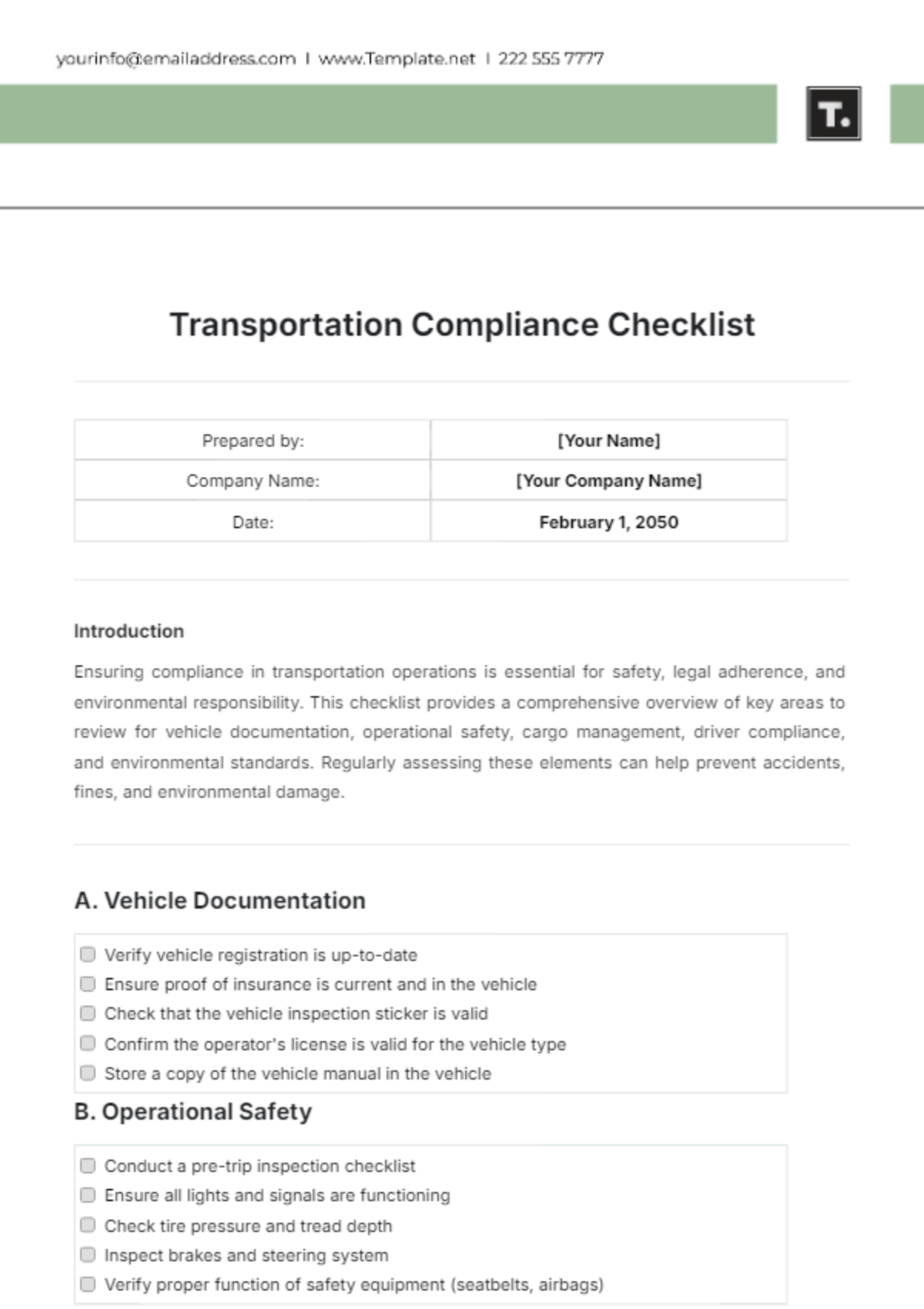

Production Phase

Post-production Phase

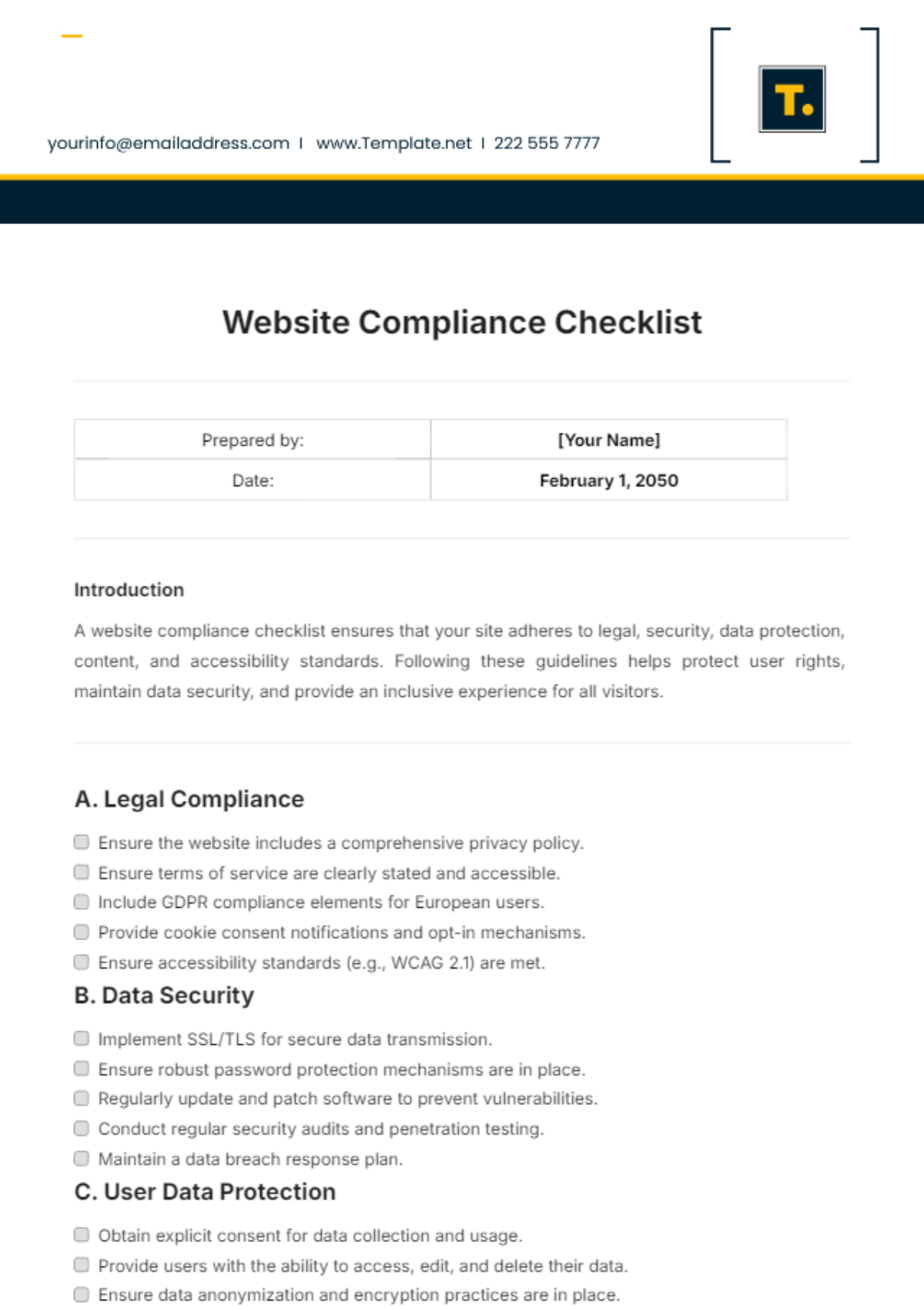

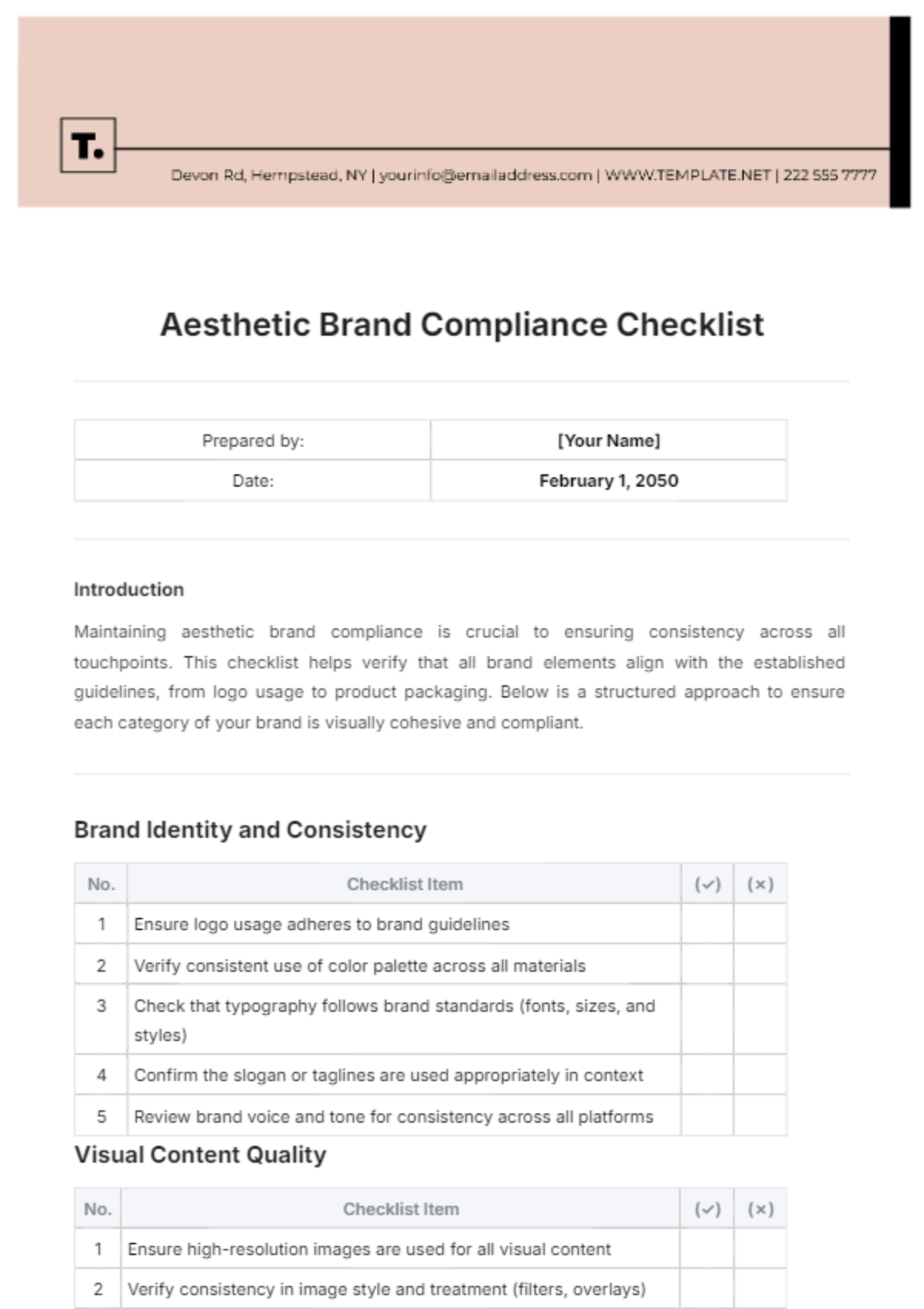

Continuous Improvement

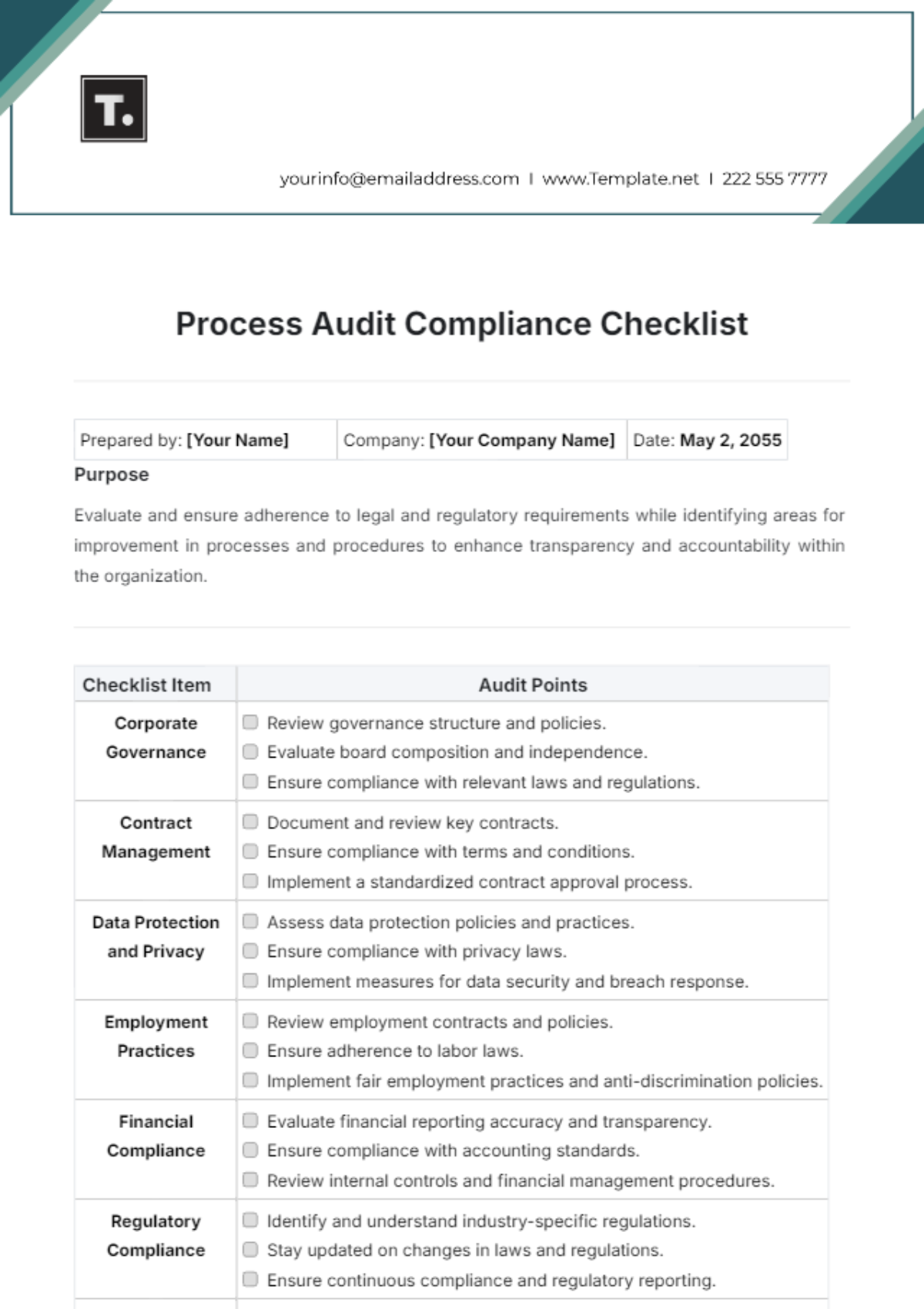

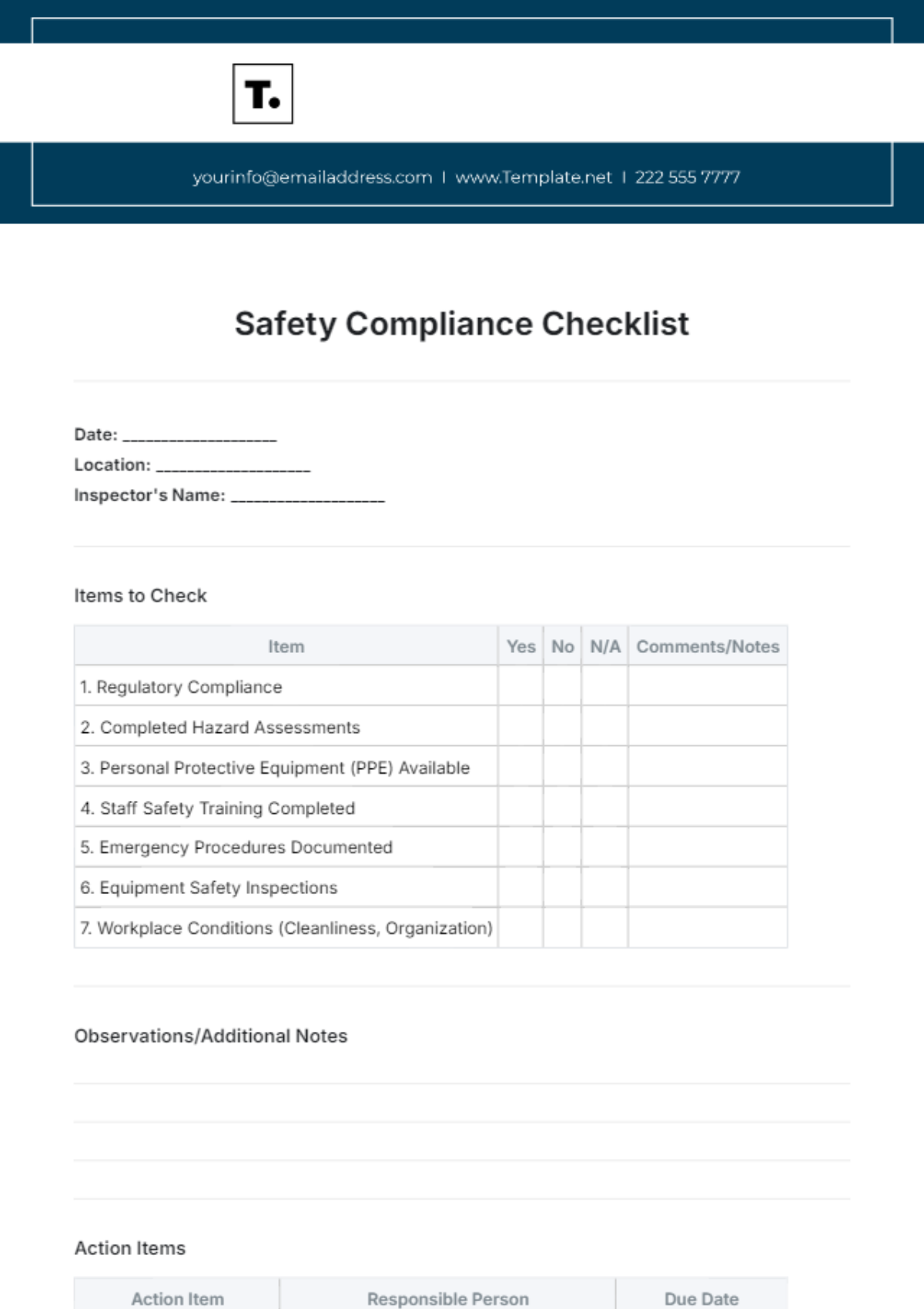

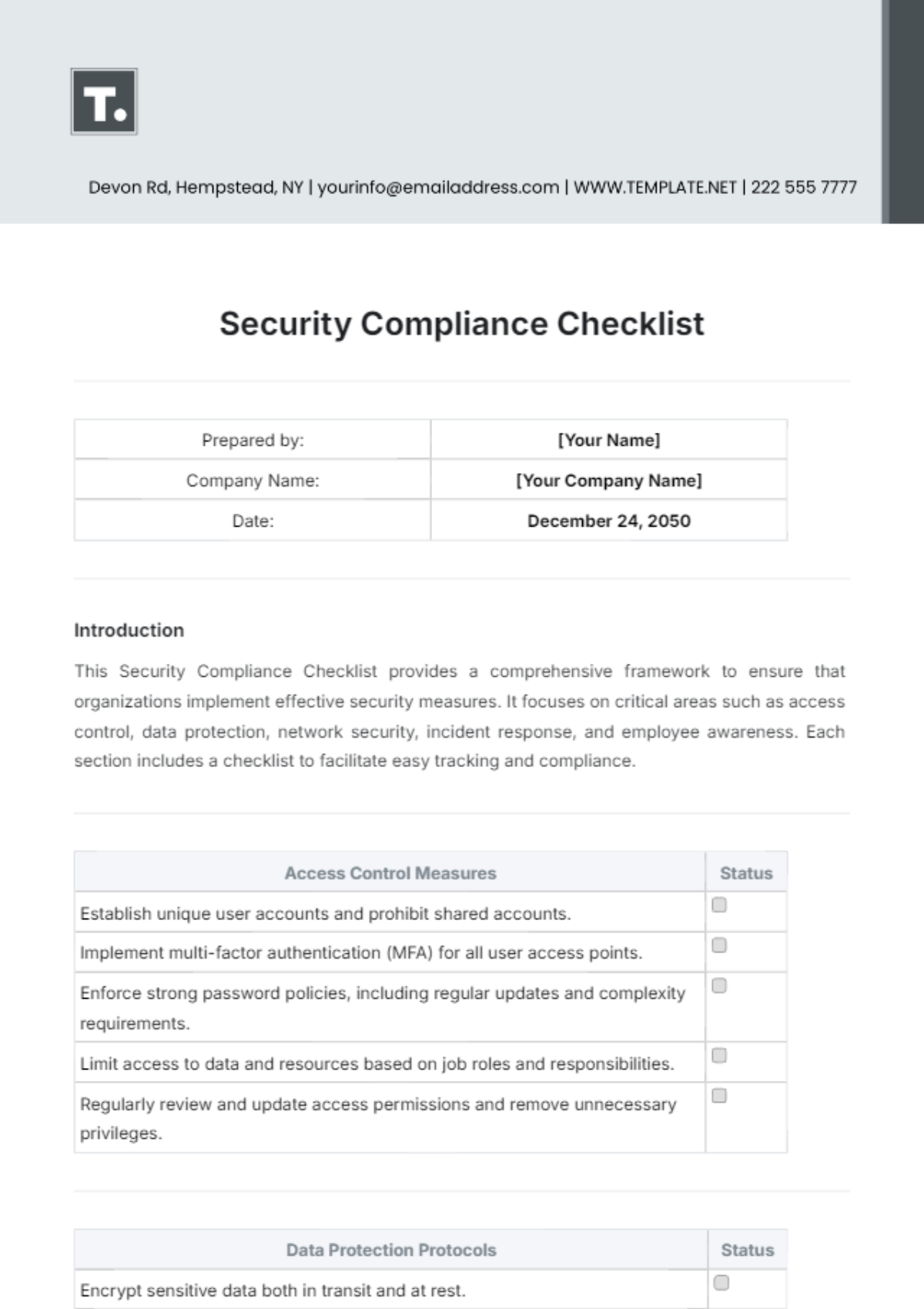

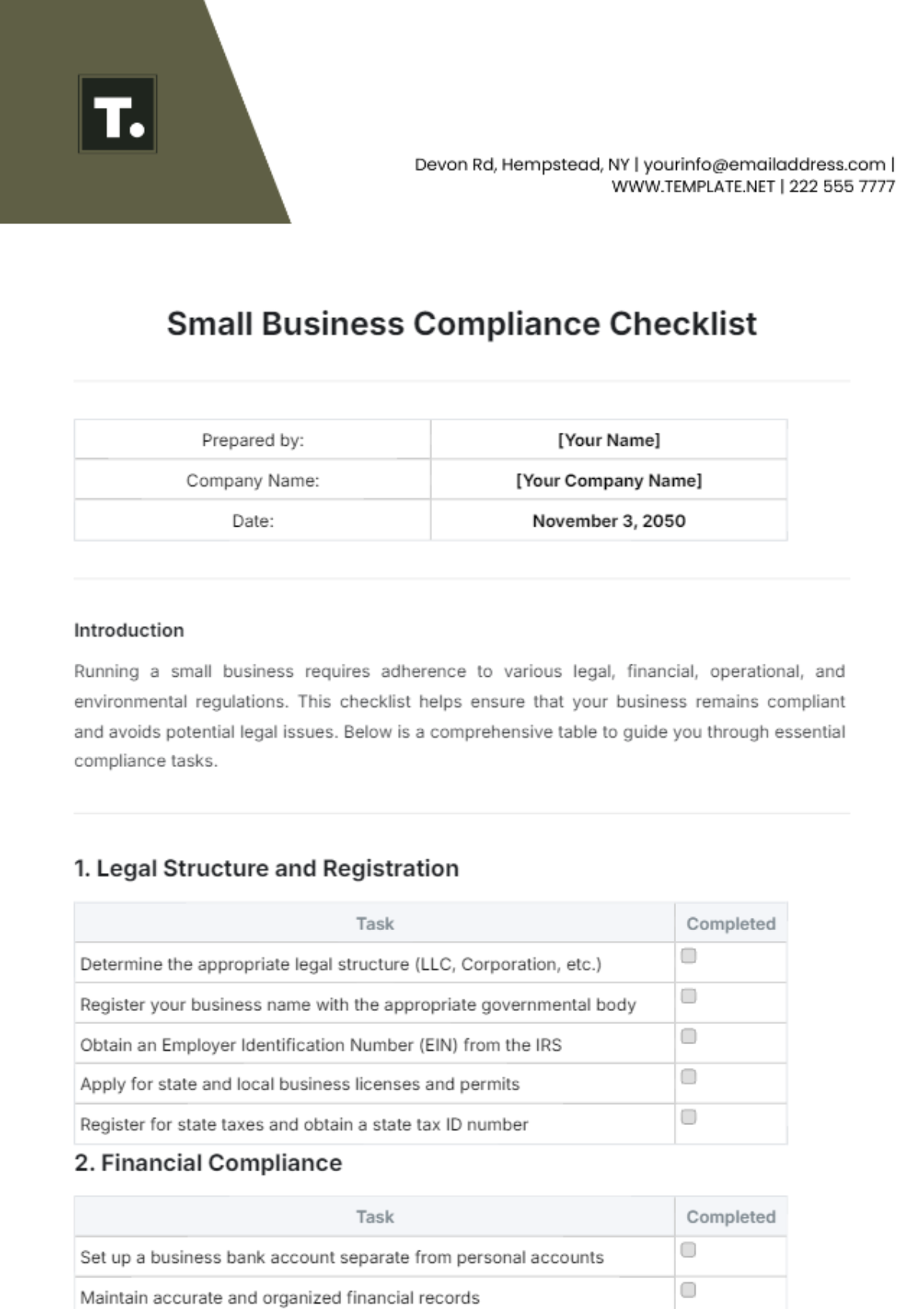

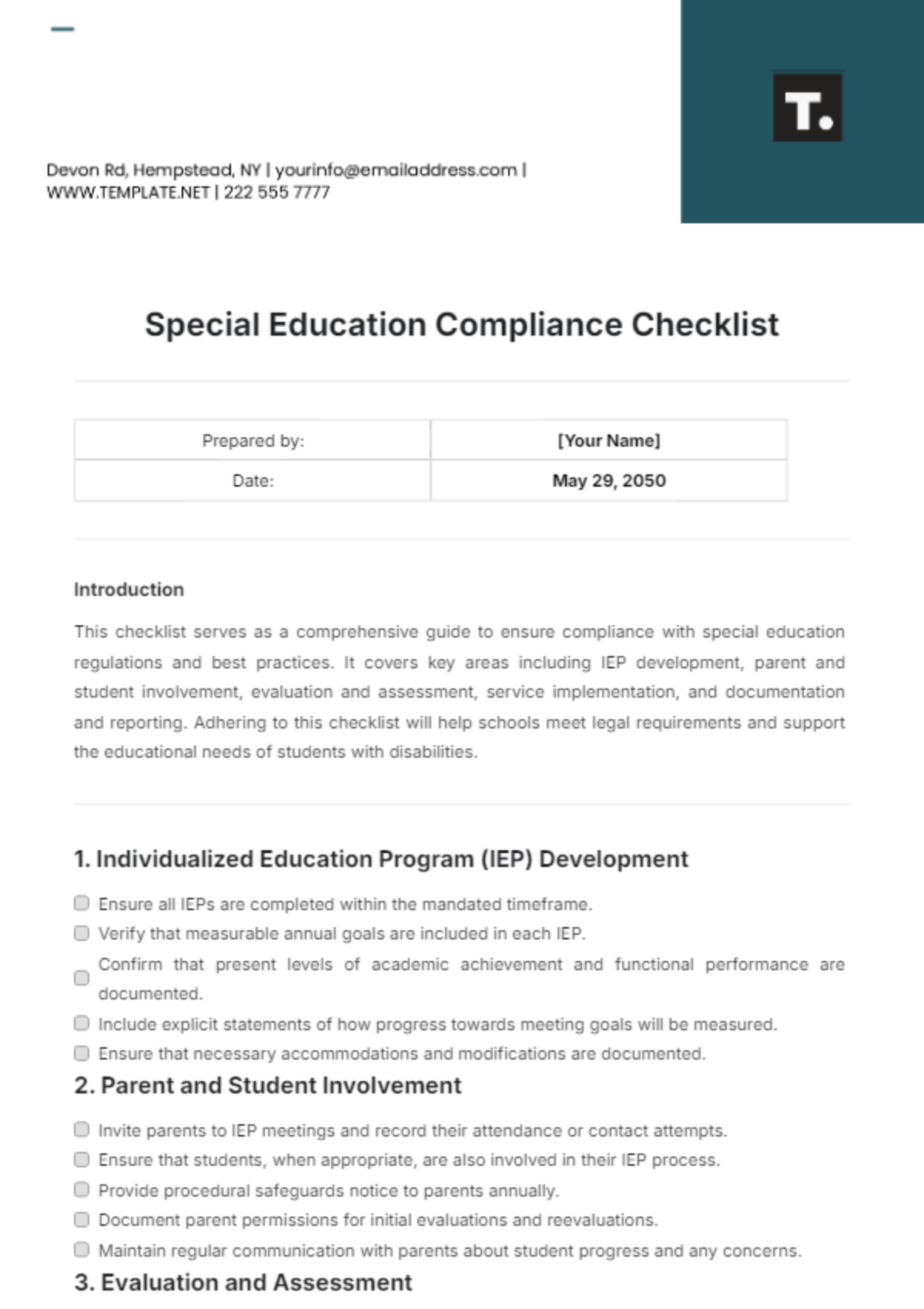

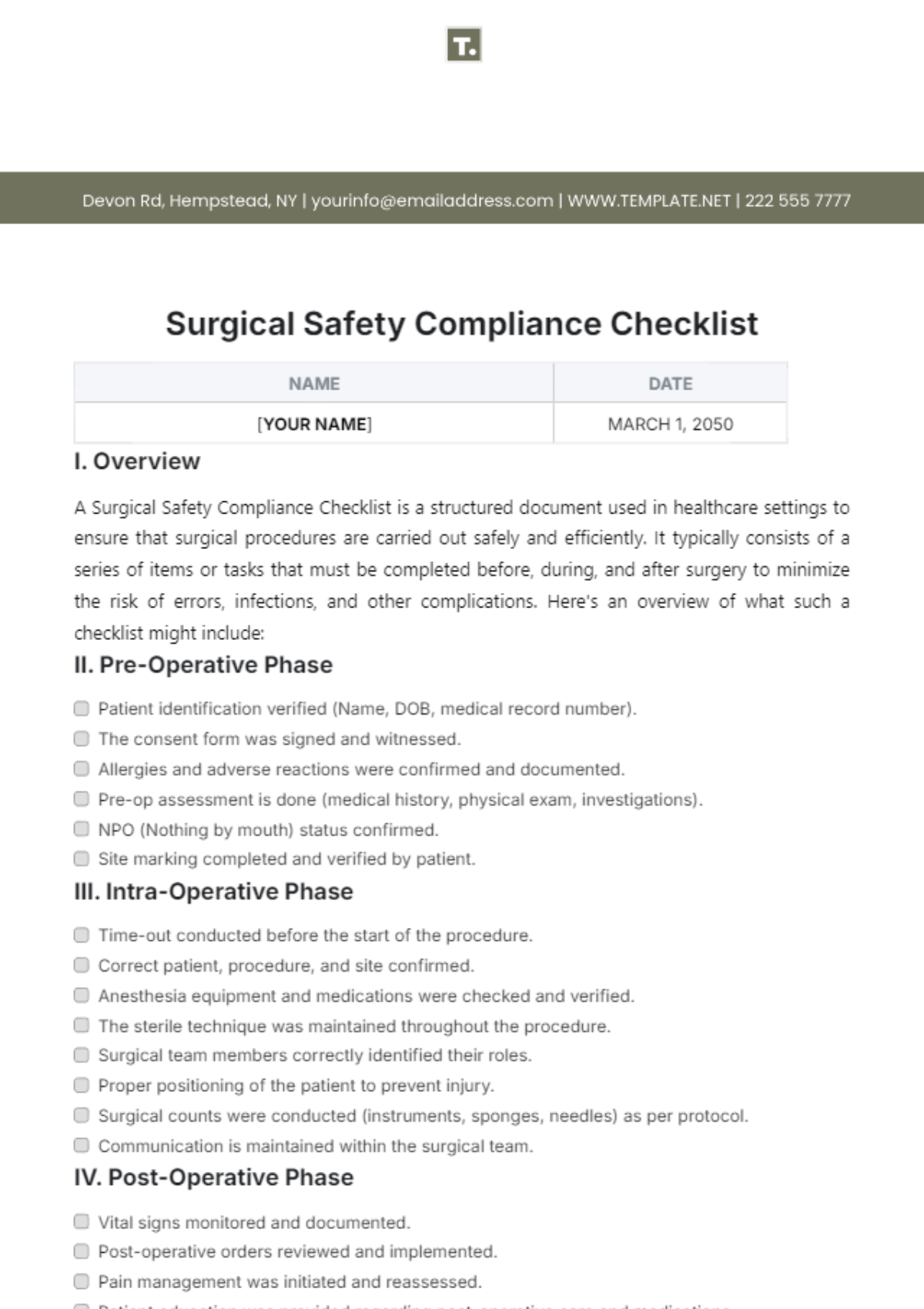

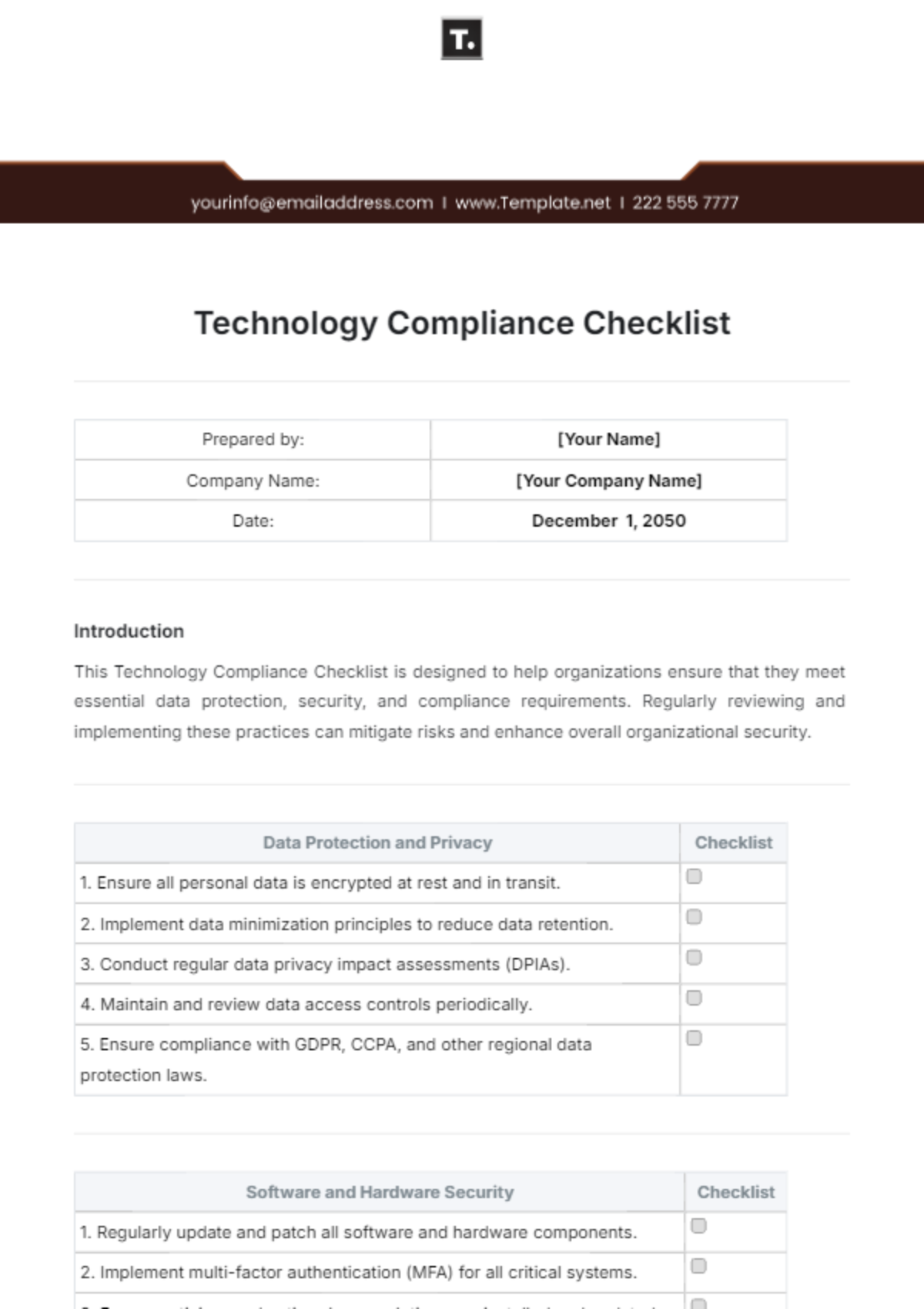

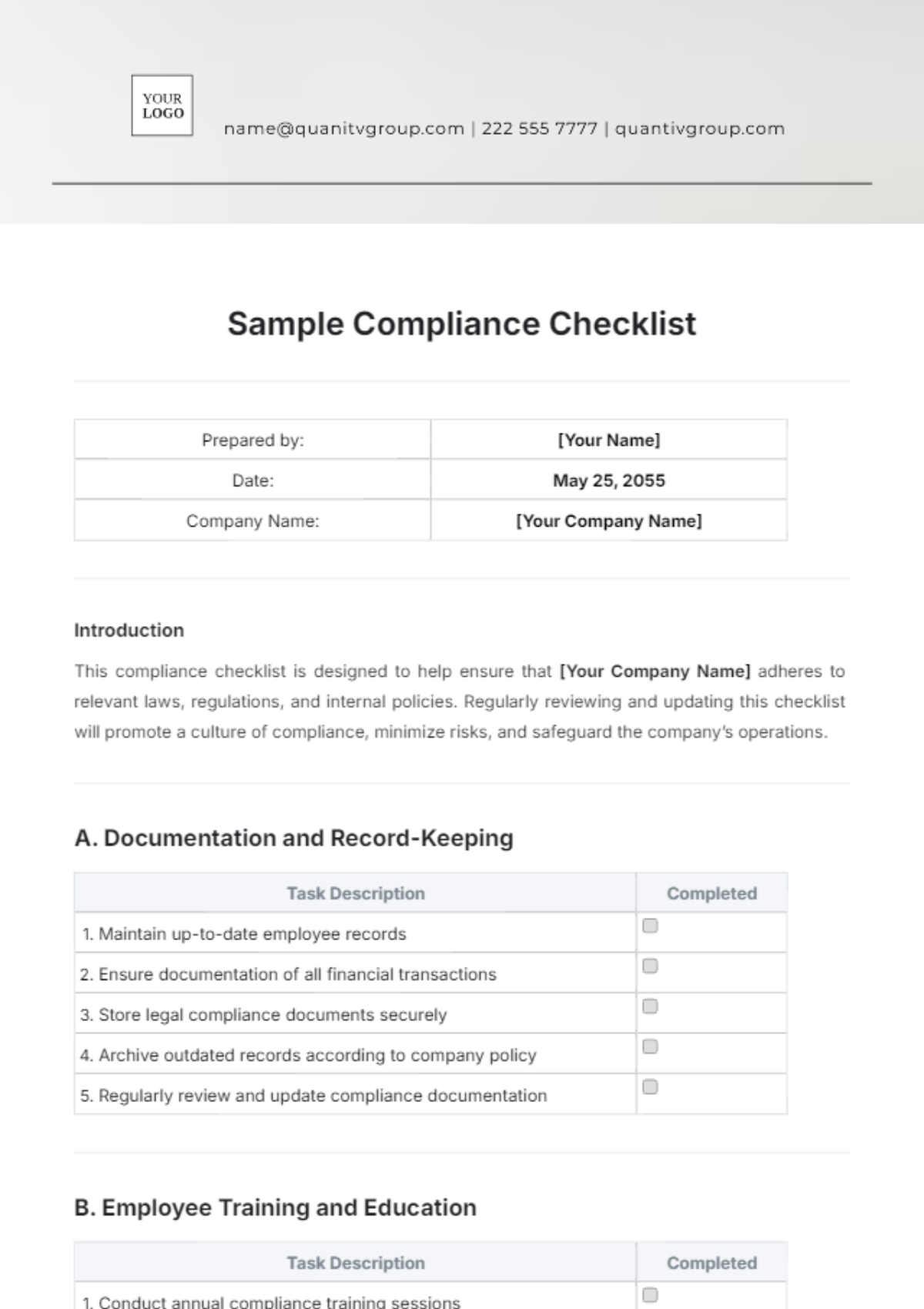

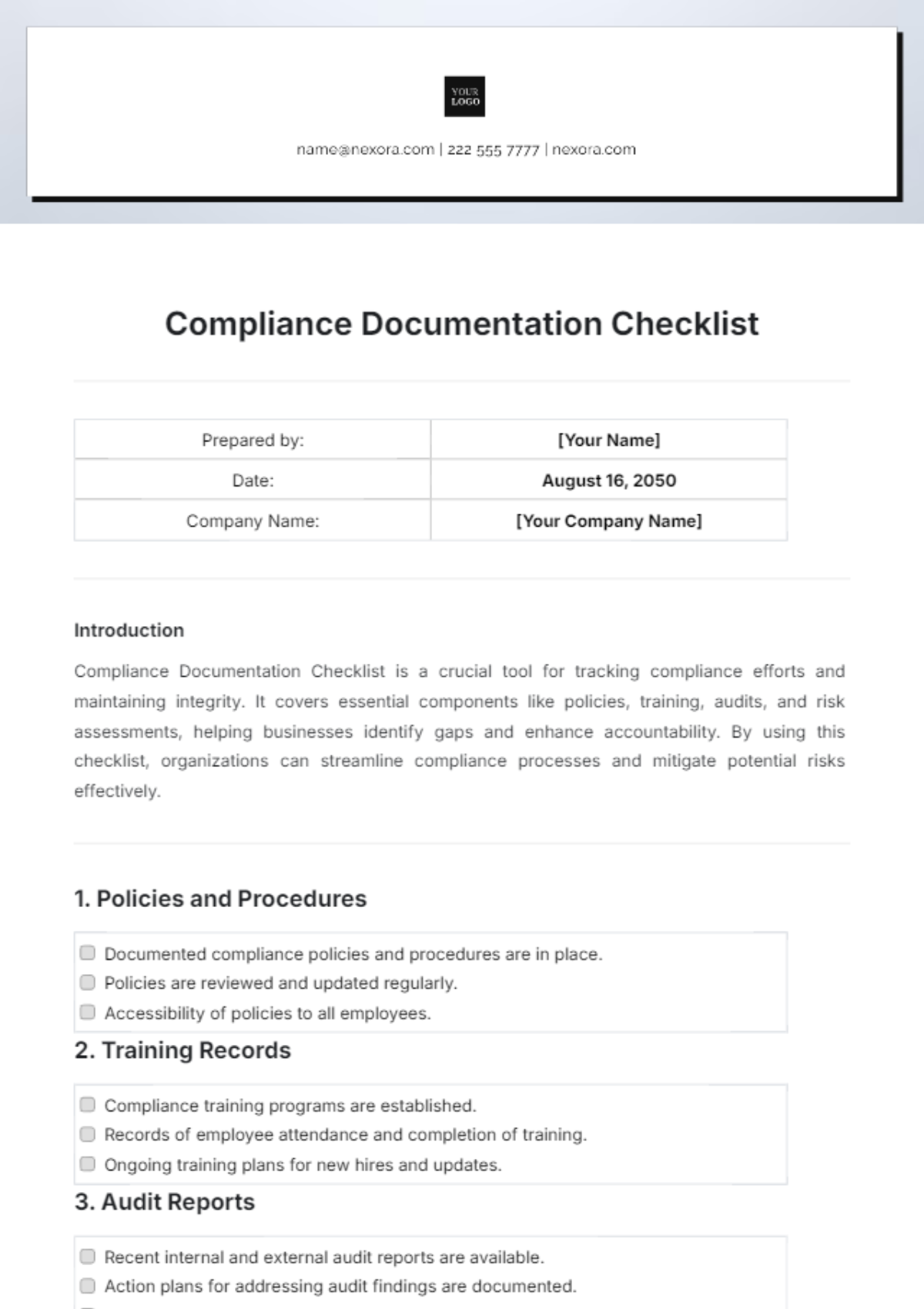

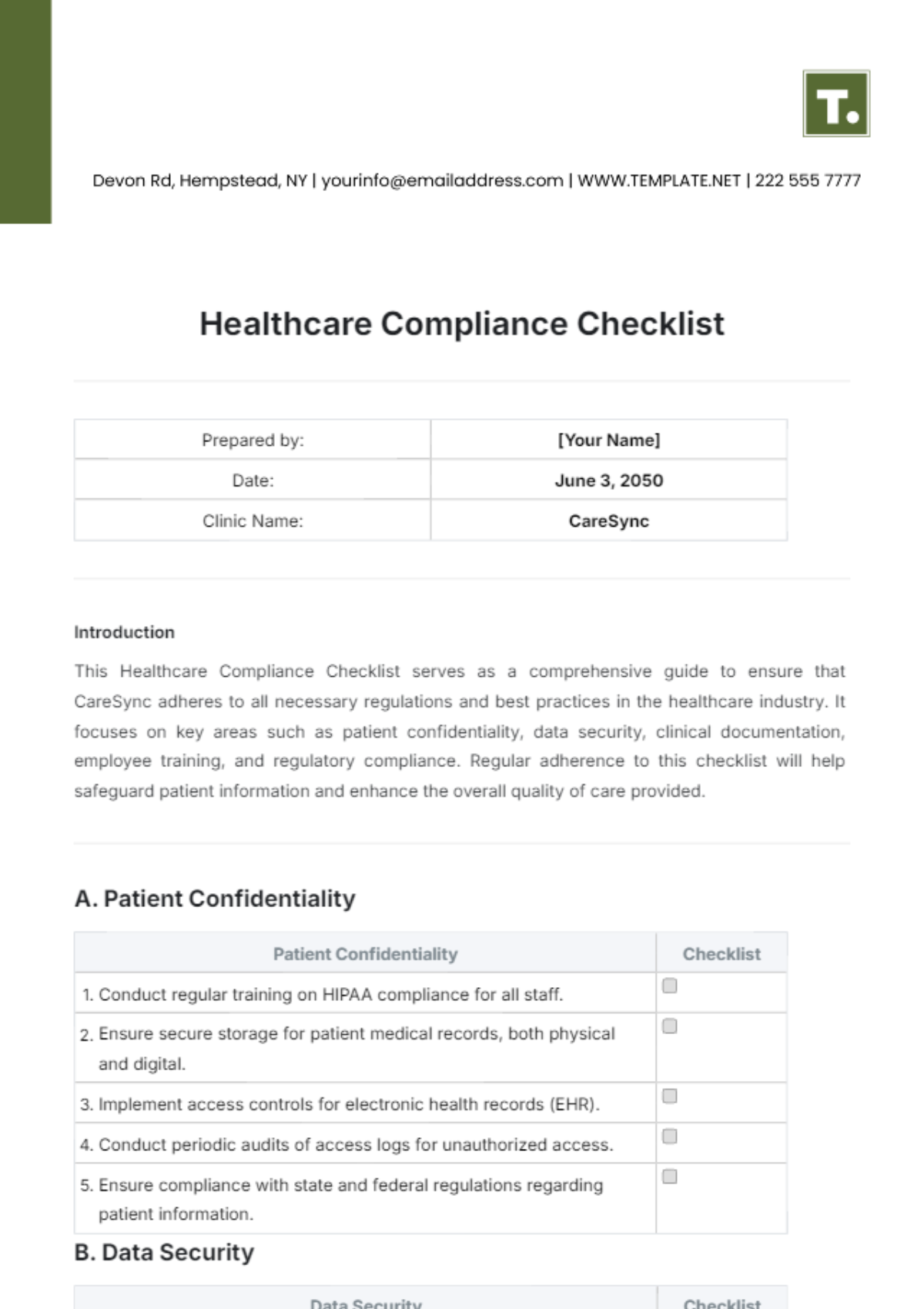

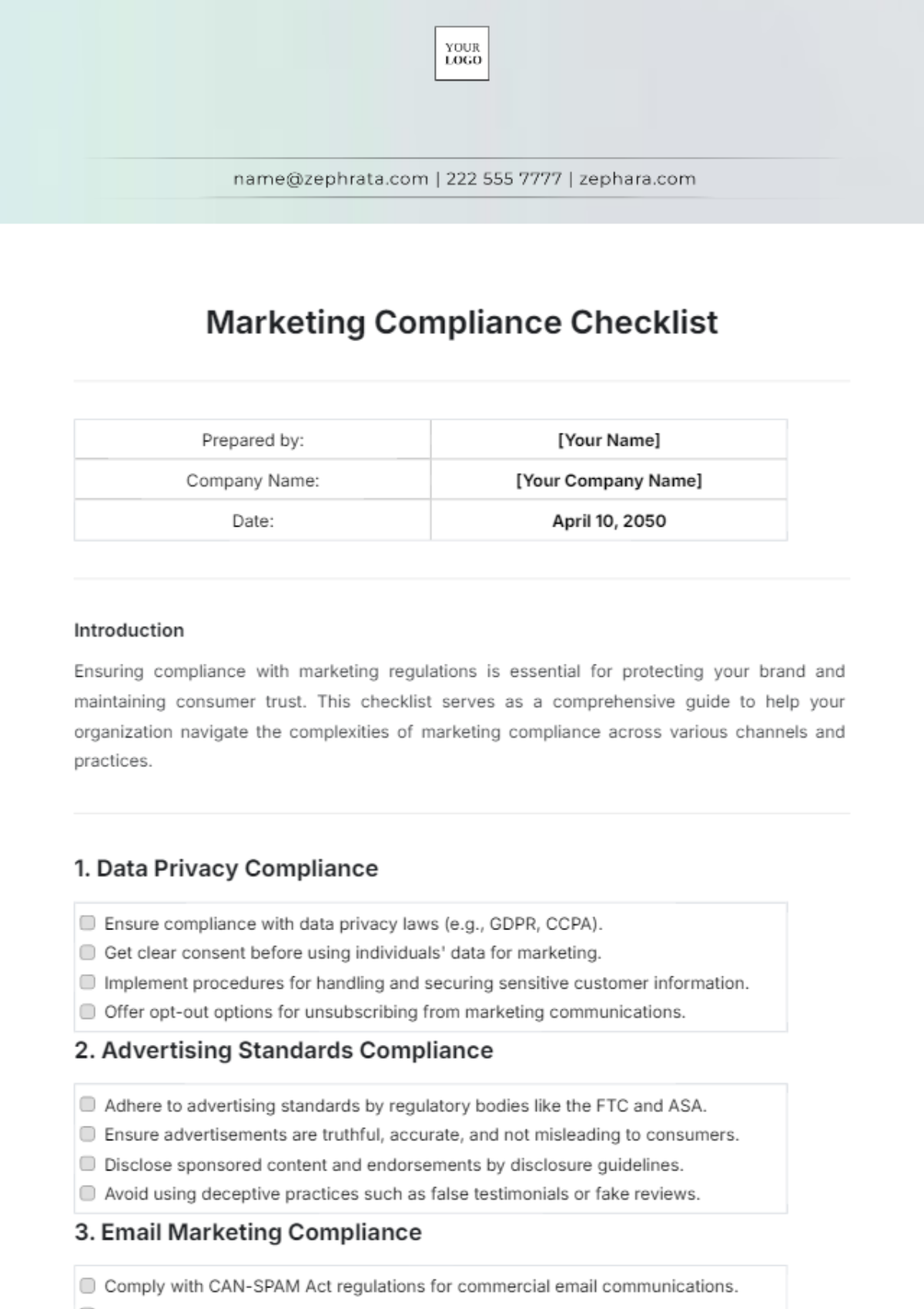

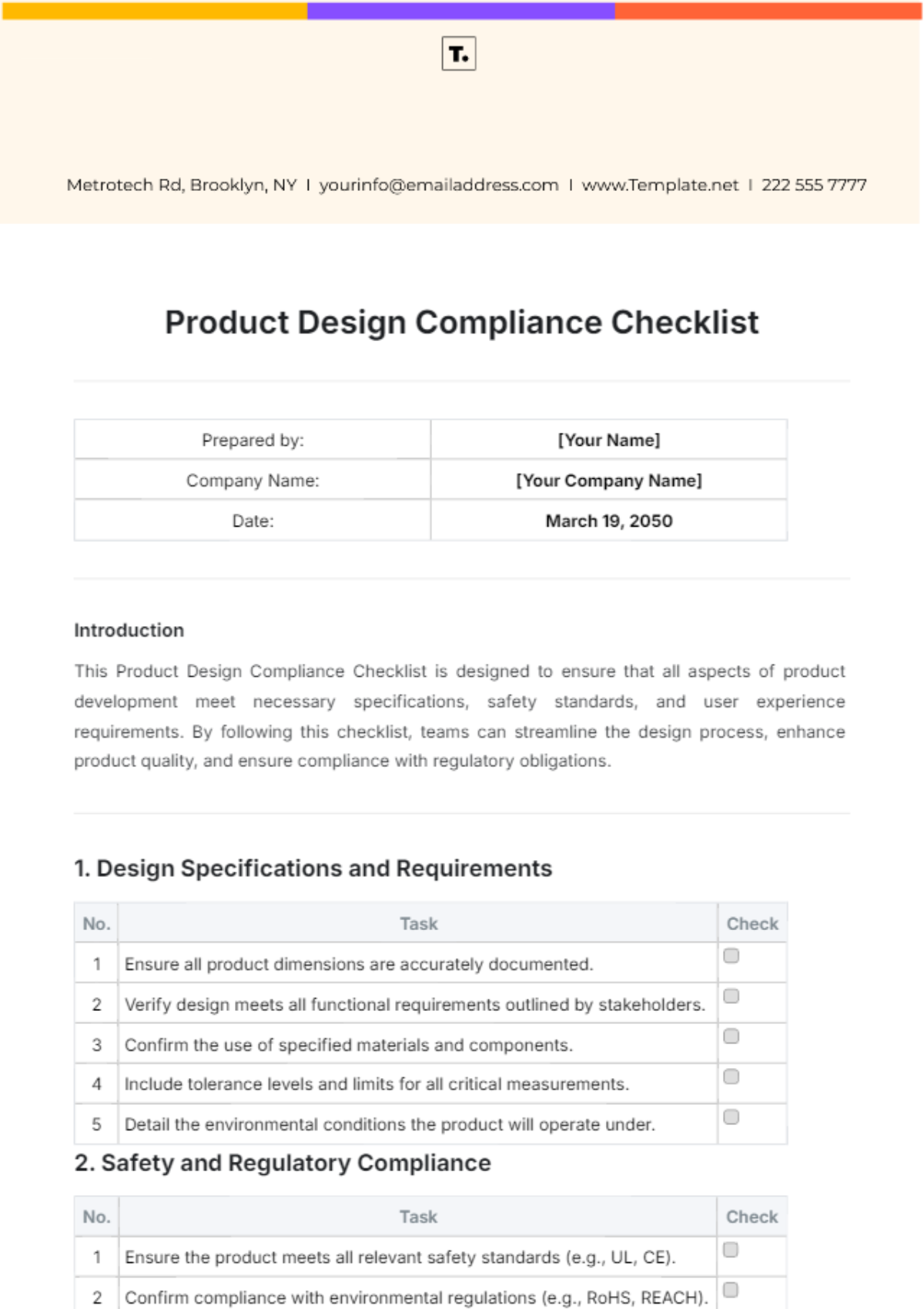

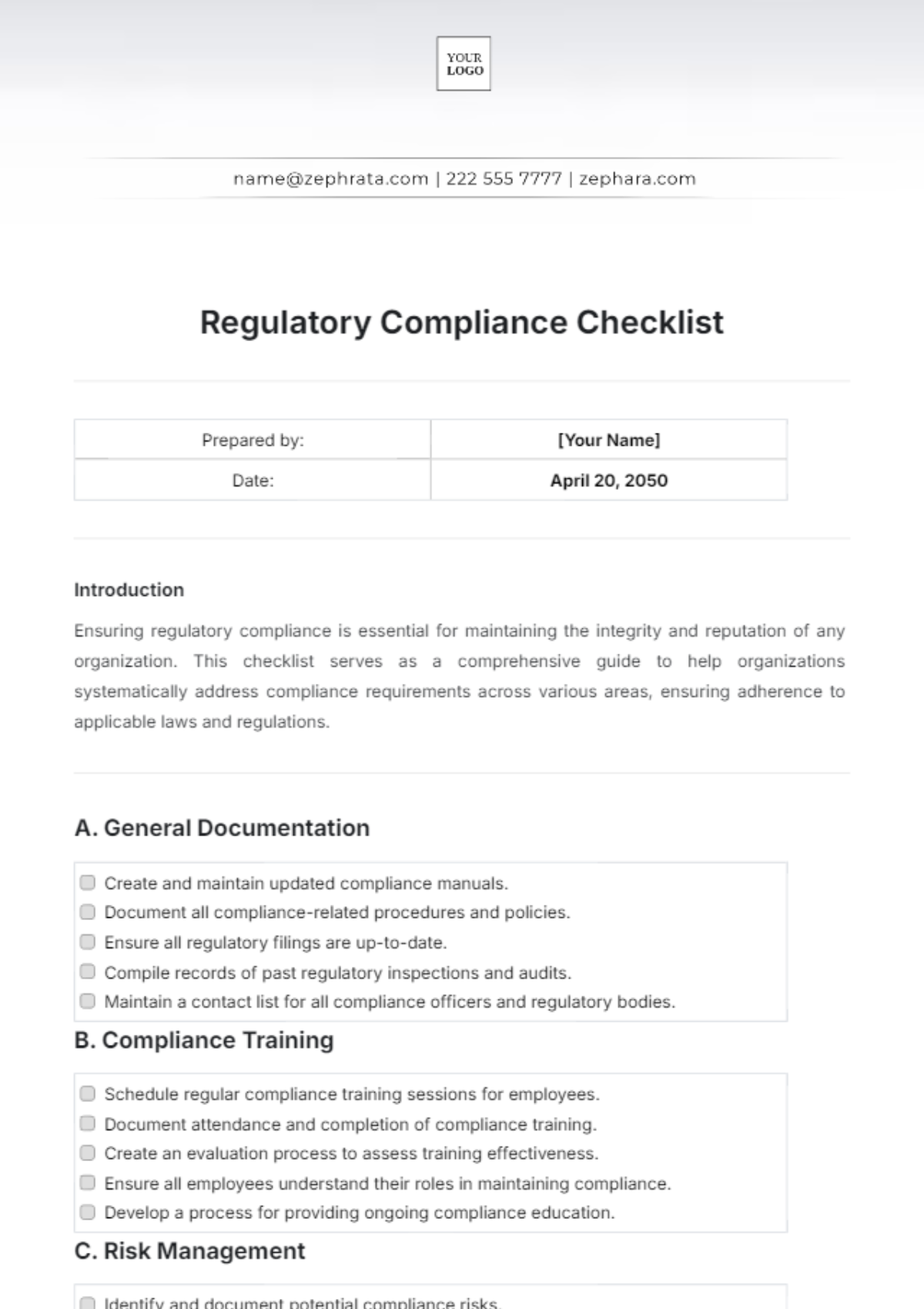

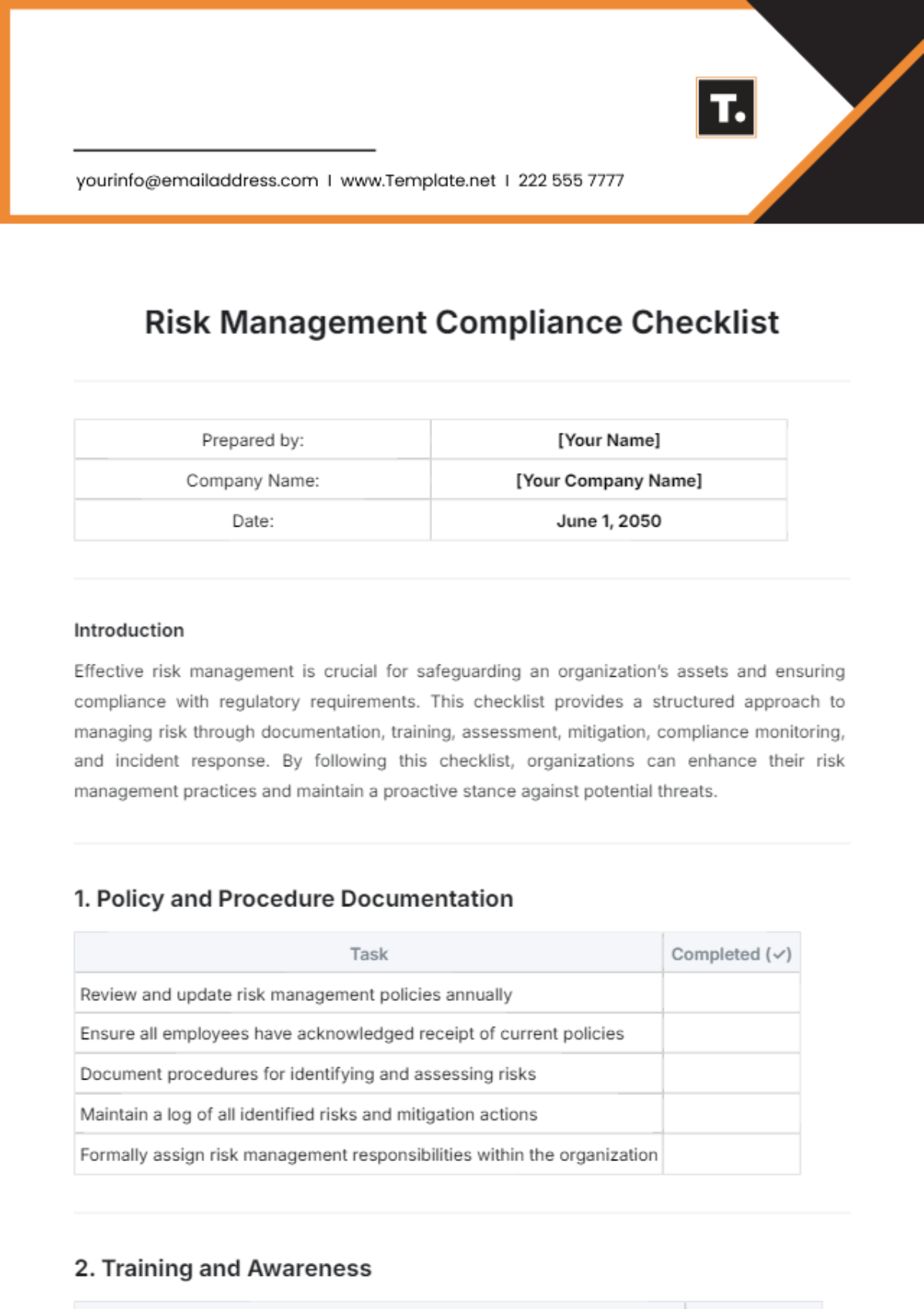

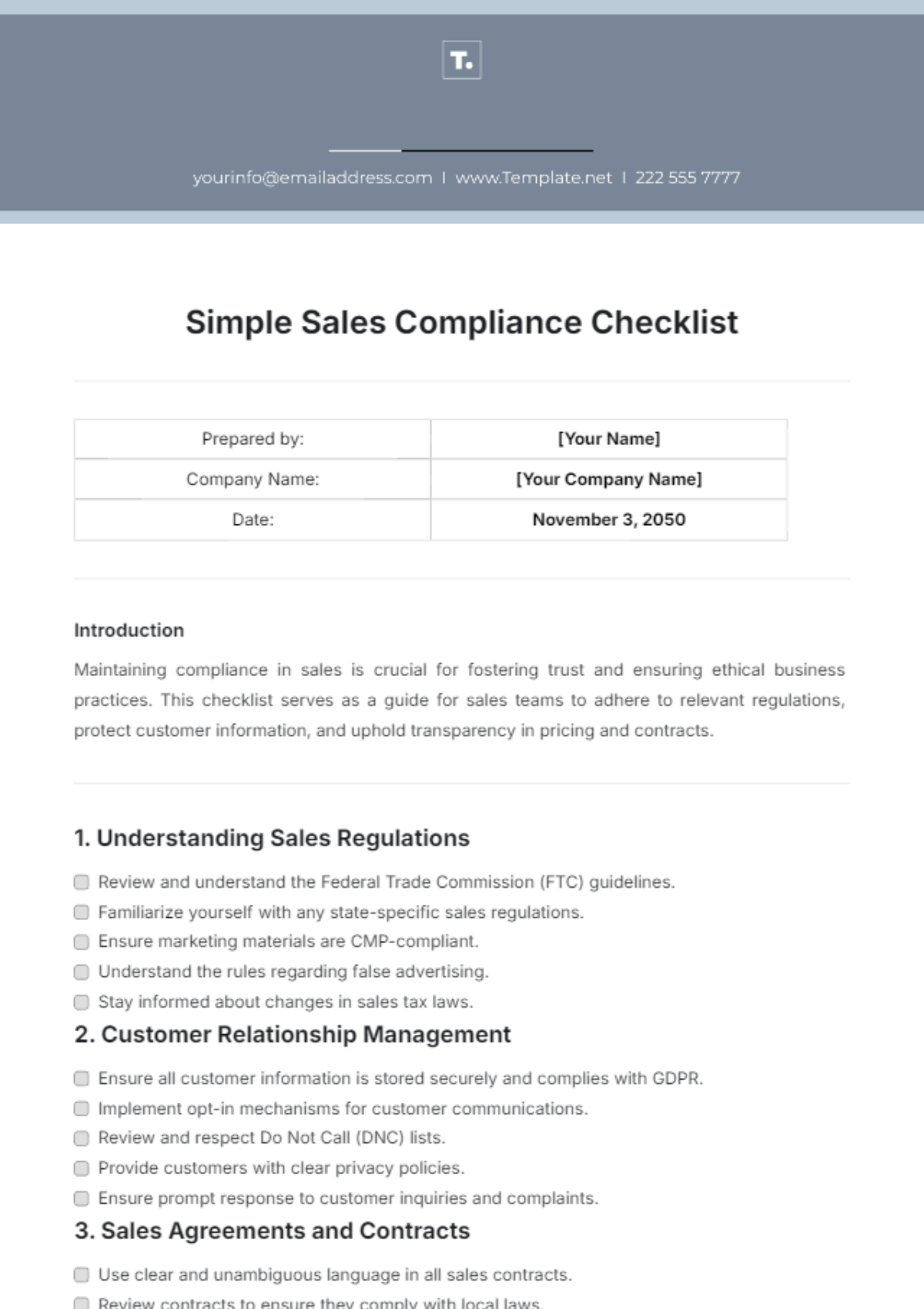

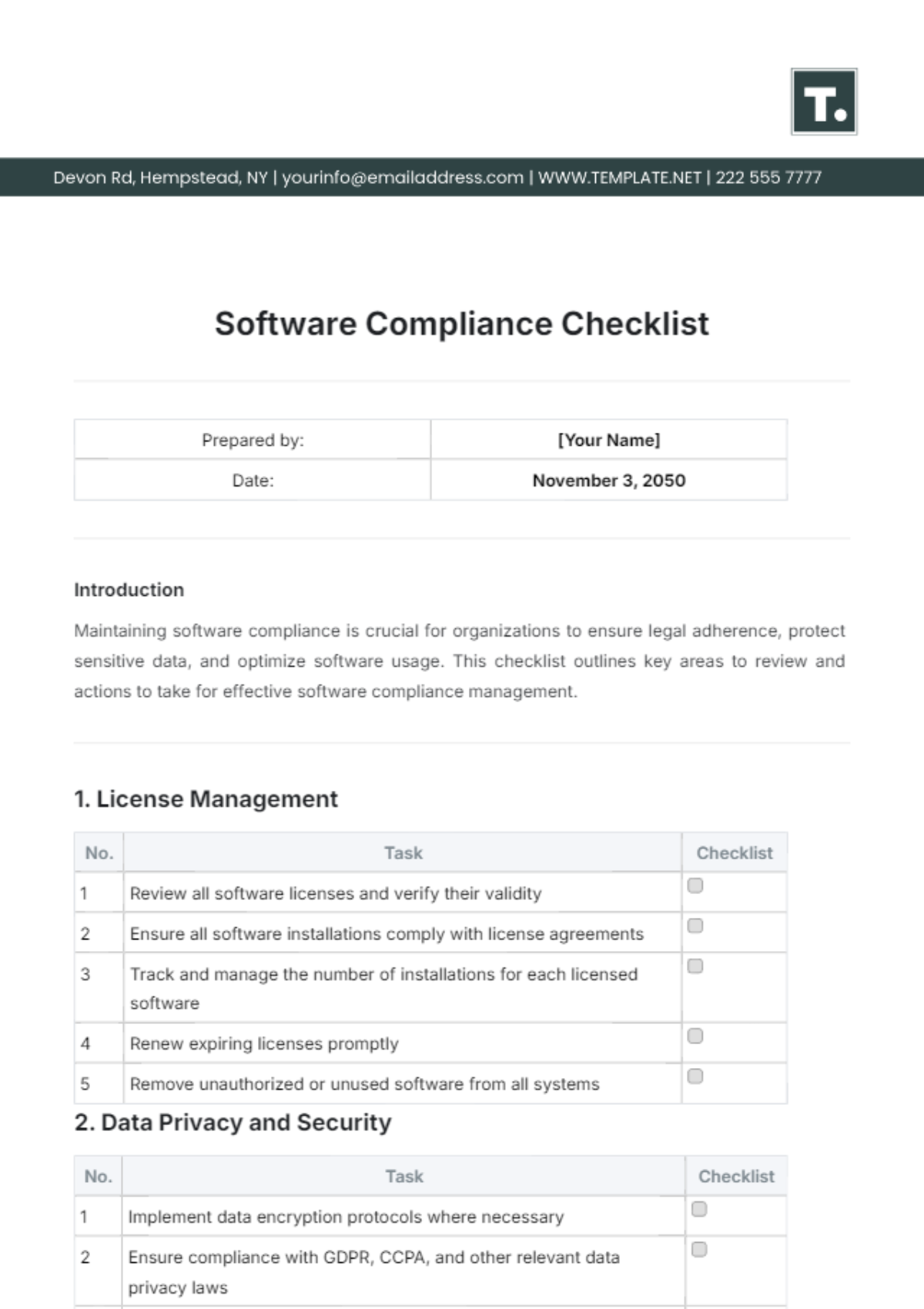

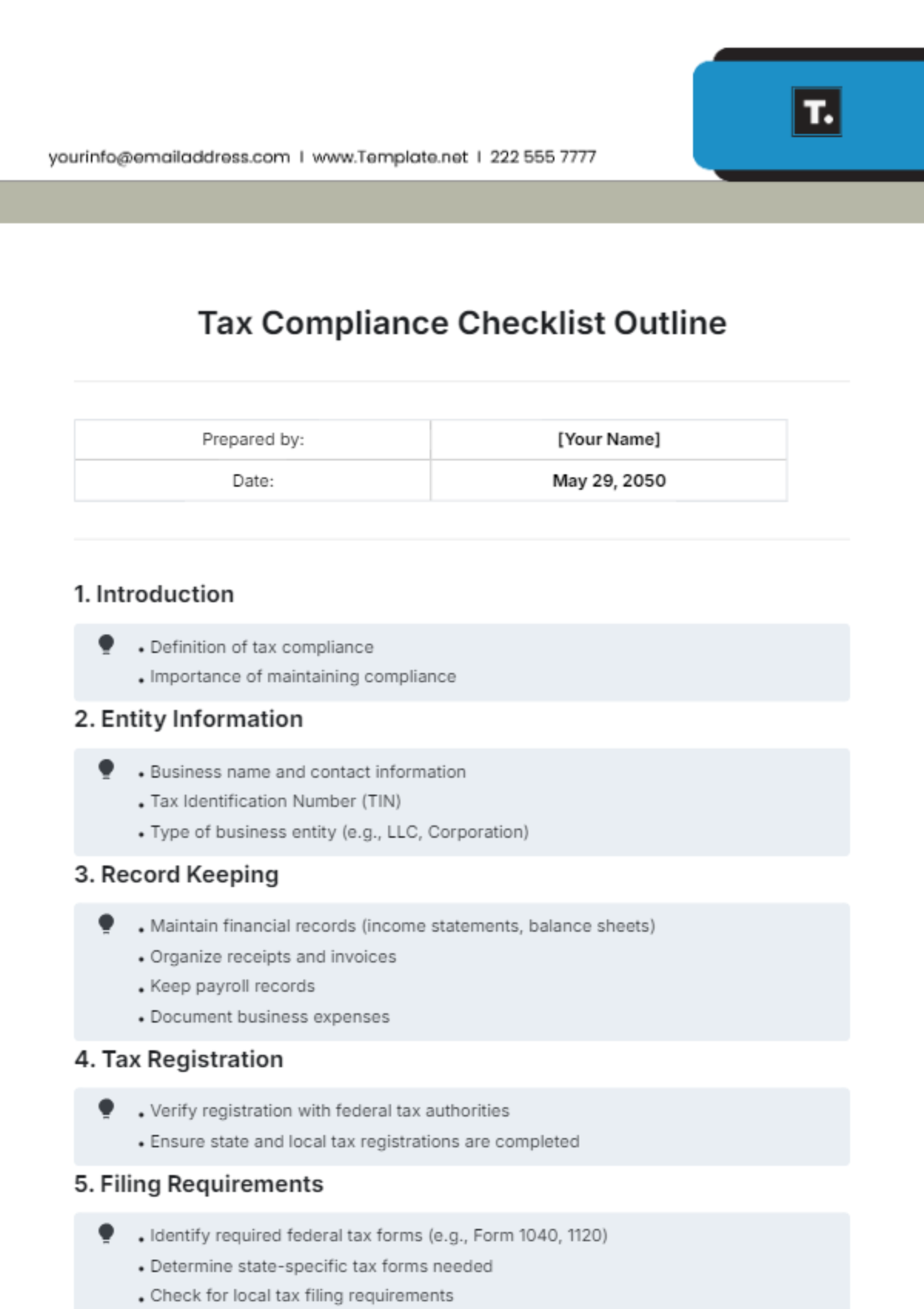

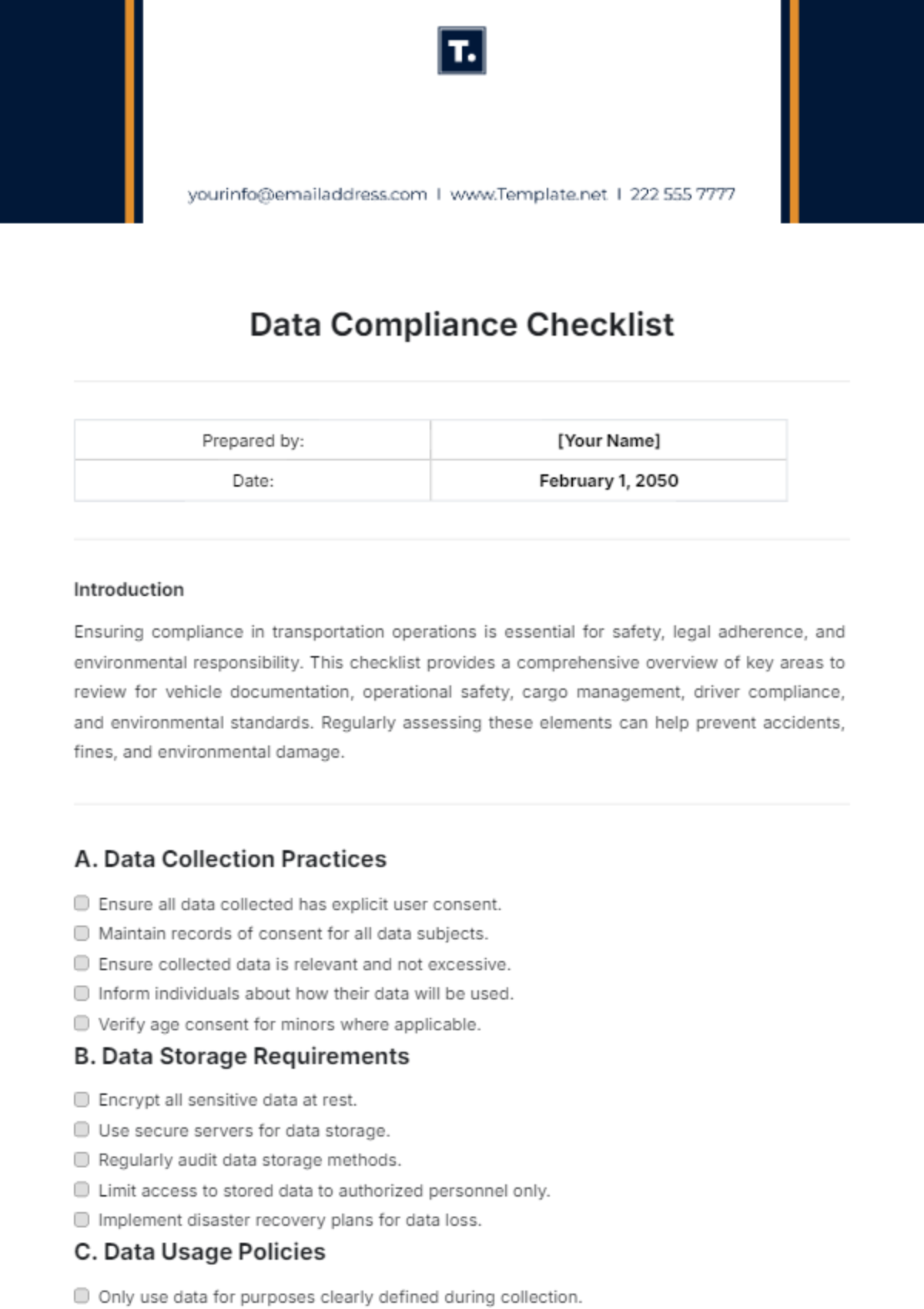

Compliance and Documentation

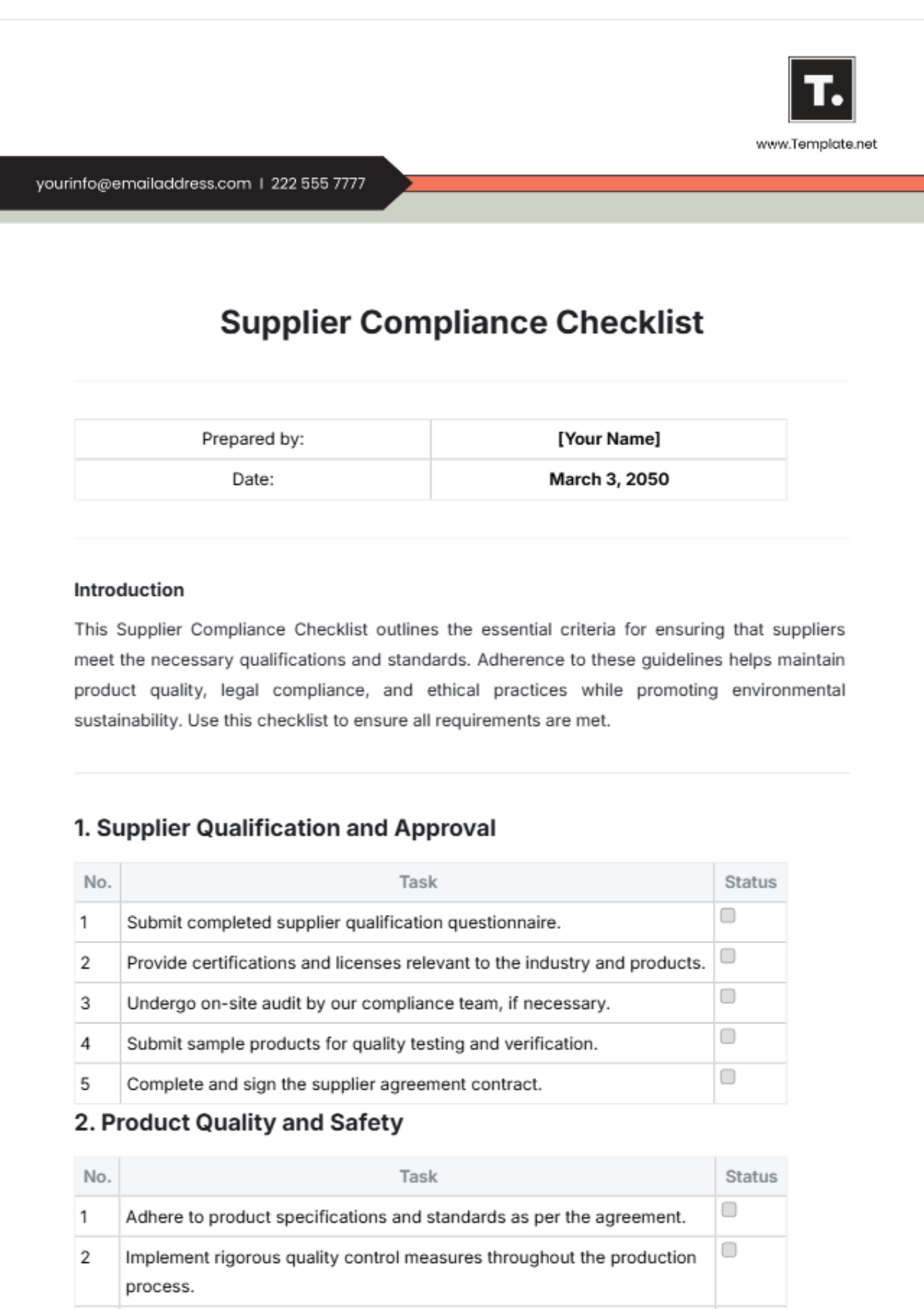

Supplier Management

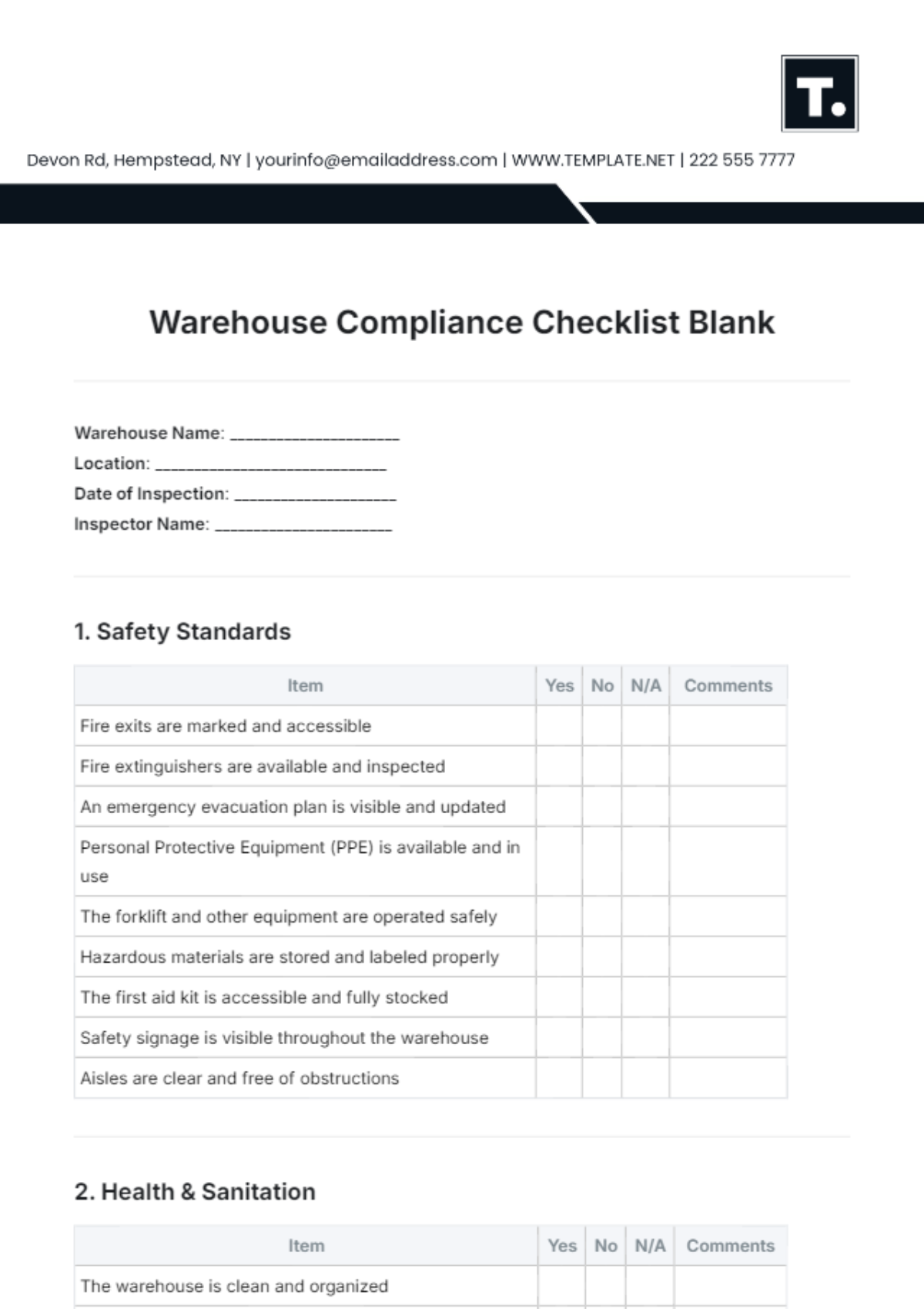

Emergency Preparedness

Operations Templates @ Template.net