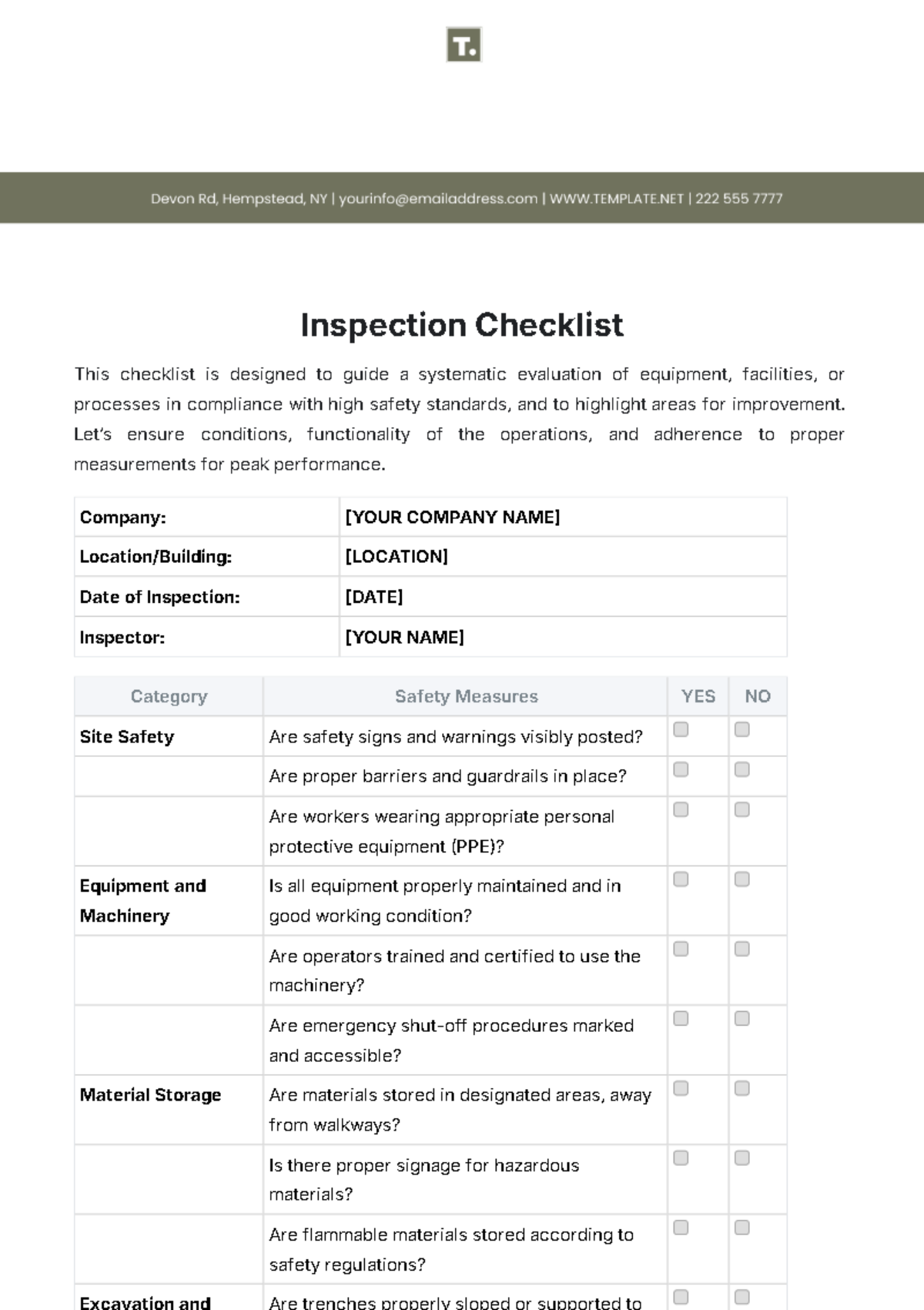

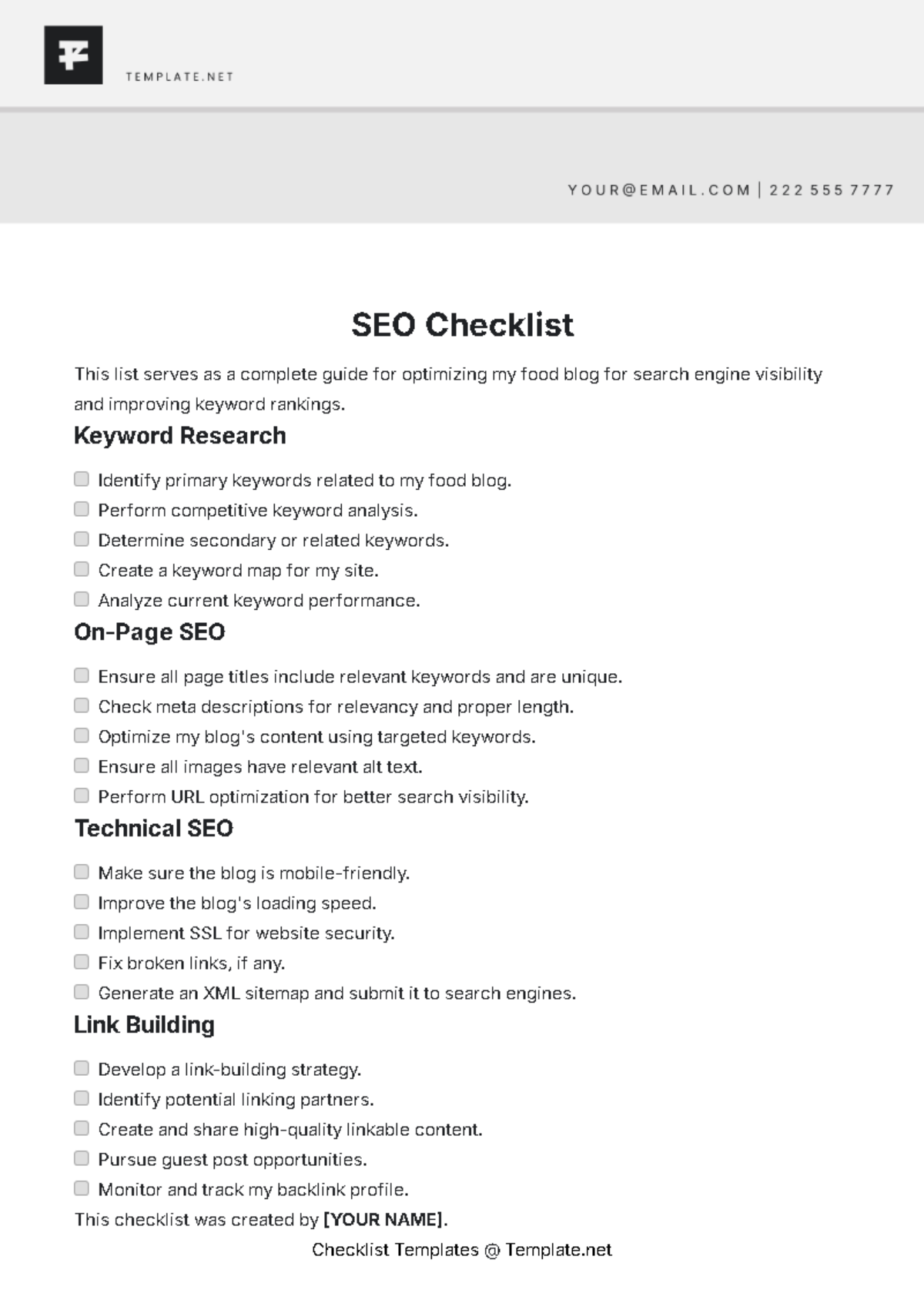

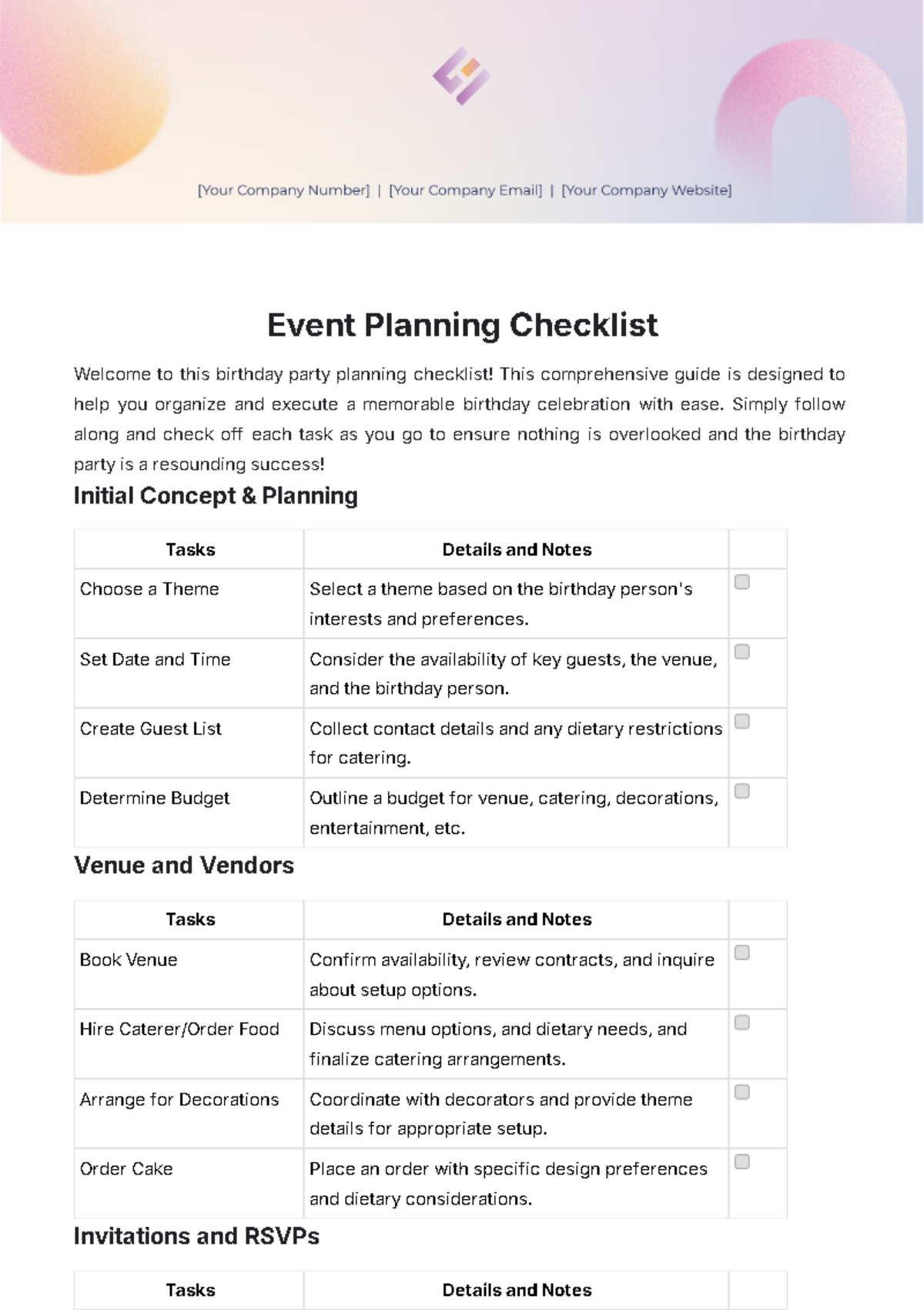

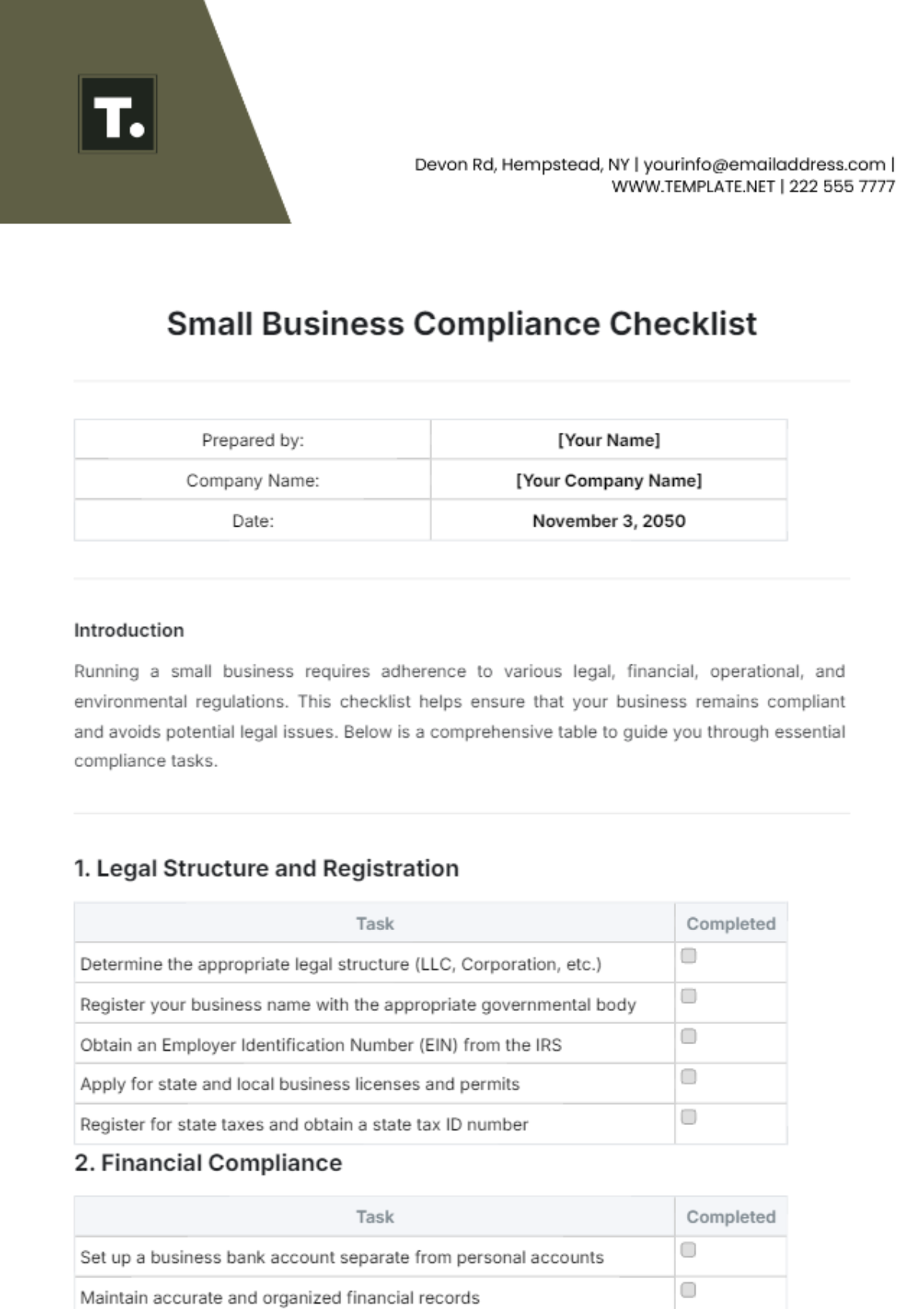

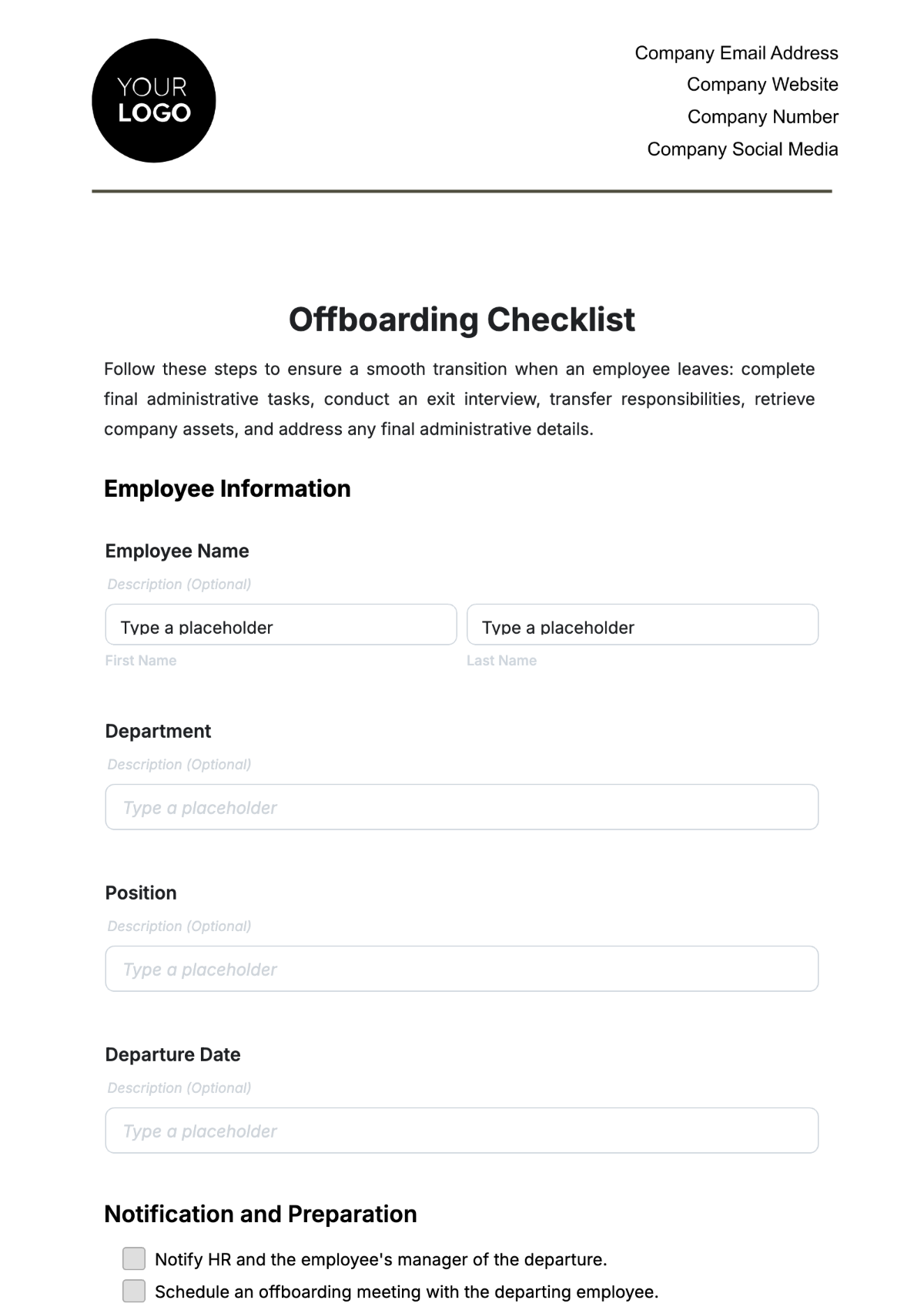

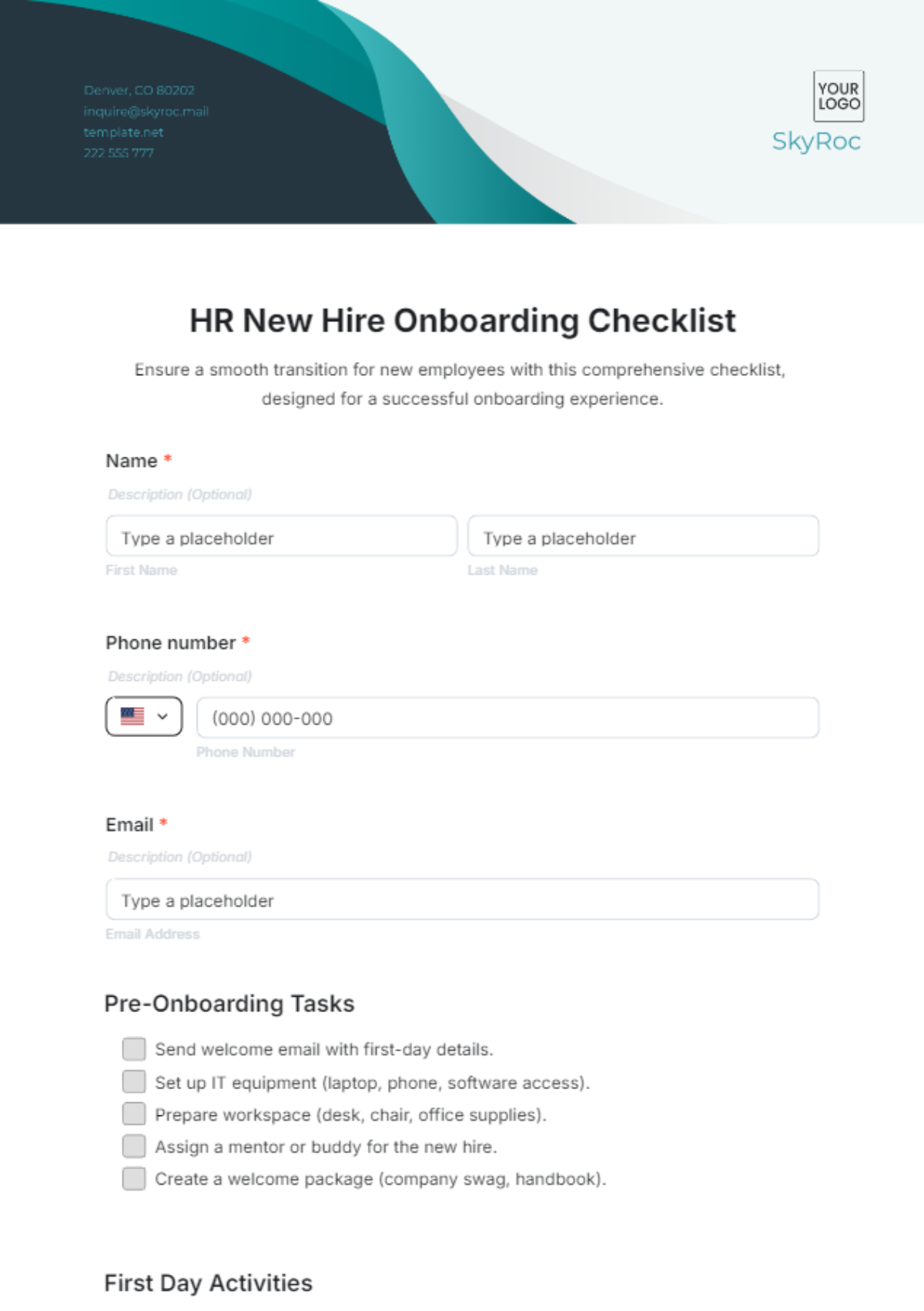

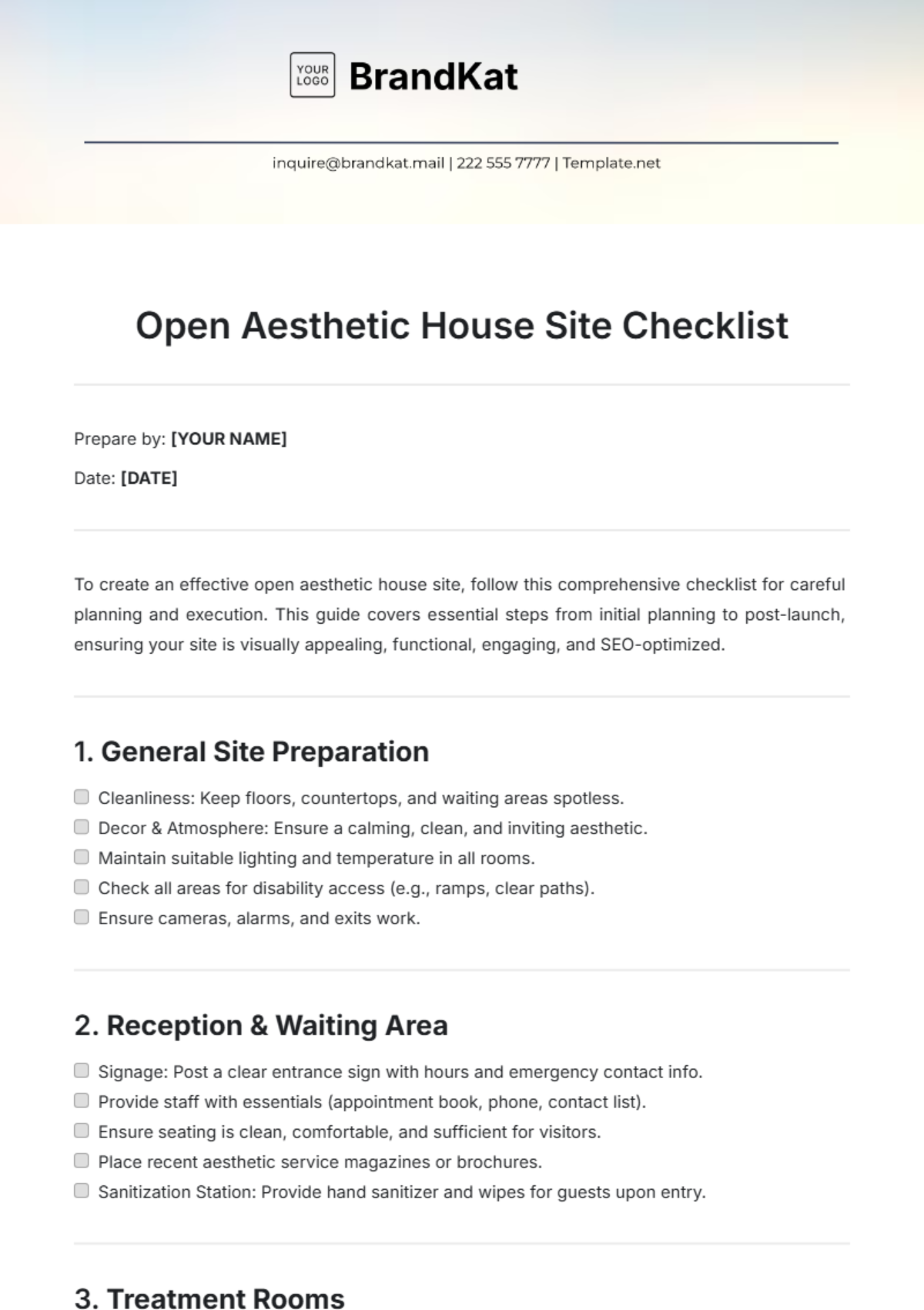

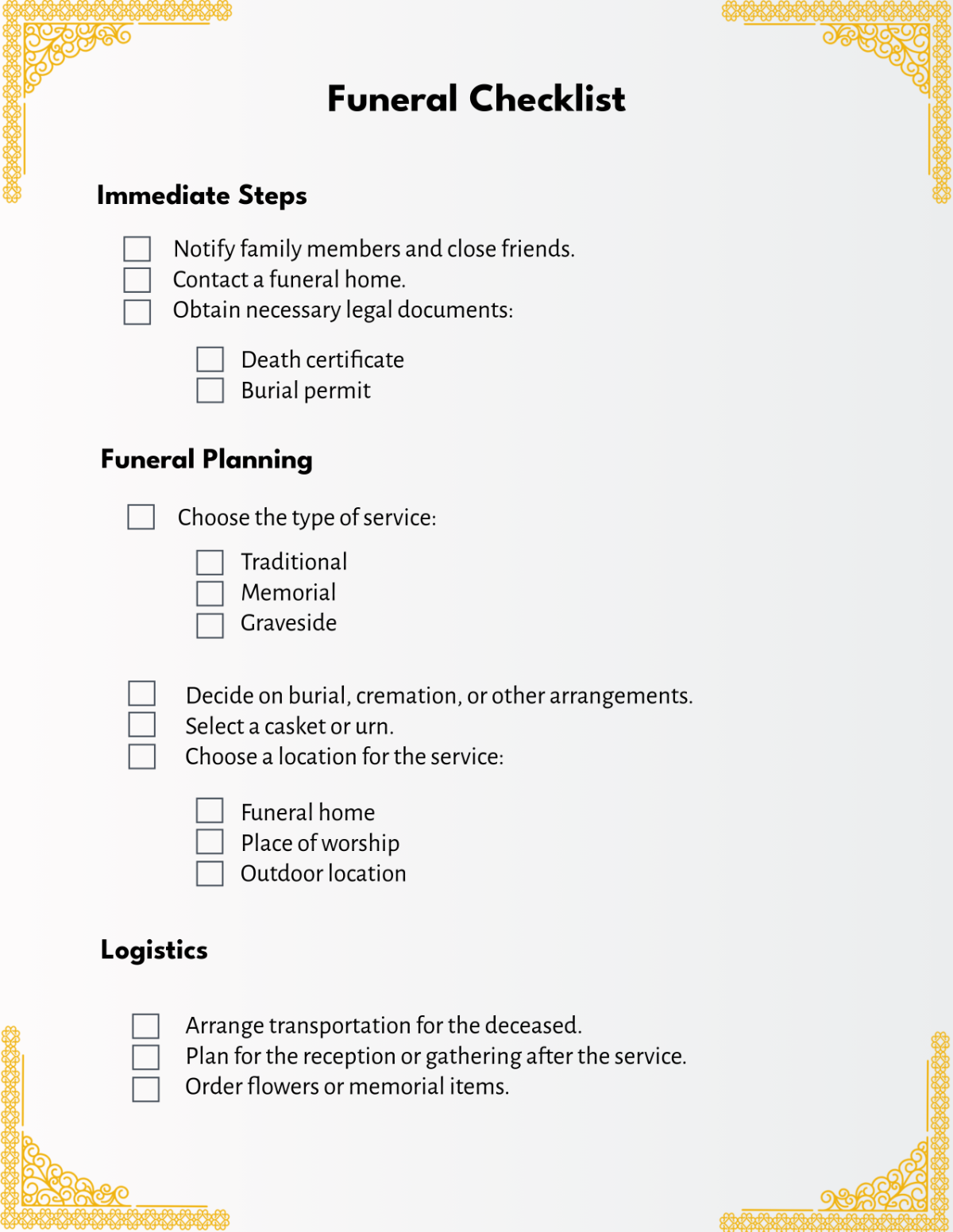

Free Machine Safety Checklist Template

Machine Safety Checklist

Prepared by | [Your Name] |

Date | [12/11/2050] |

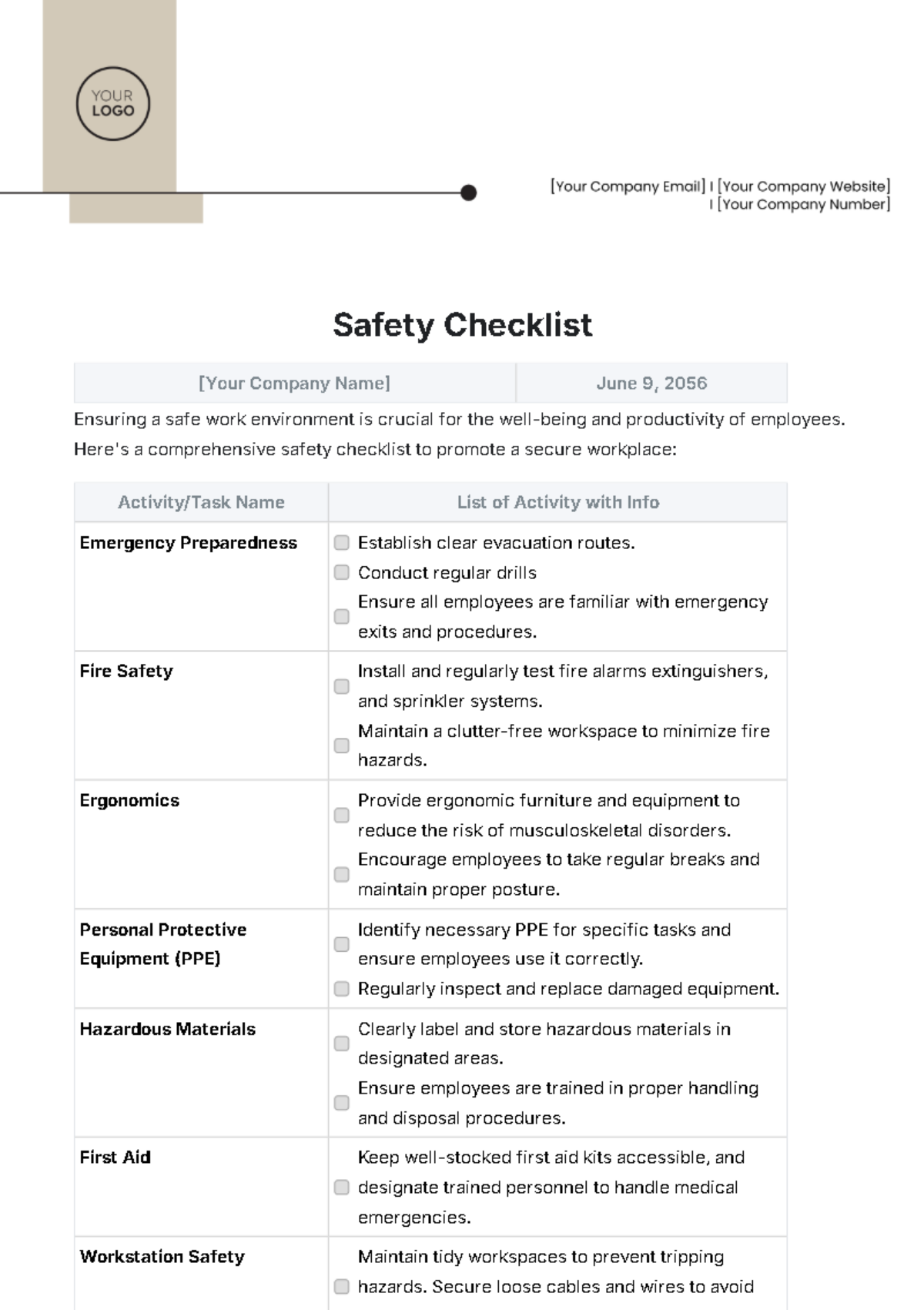

General Safety

Machine Guards

All machine parts posing hazards are properly guarded.

Guards are securely attached but easily removable for maintenance.

Emergency Stop

A clearly marked, accessible emergency stop button is in place.

The emergency stop button functions correctly.

Warning Labels

Warning labels and signs are visible, legible, and conform to industry standards.

Machine Guards

All machine parts posing hazards are properly guarded.

Guards are securely attached but easily removable for maintenance.

Emergency Stop

A clearly marked, accessible emergency stop button is in place.

The emergency stop button functions correctly.

Warning Labels

Warning labels and signs are visible, legible, and conform to industry standards.

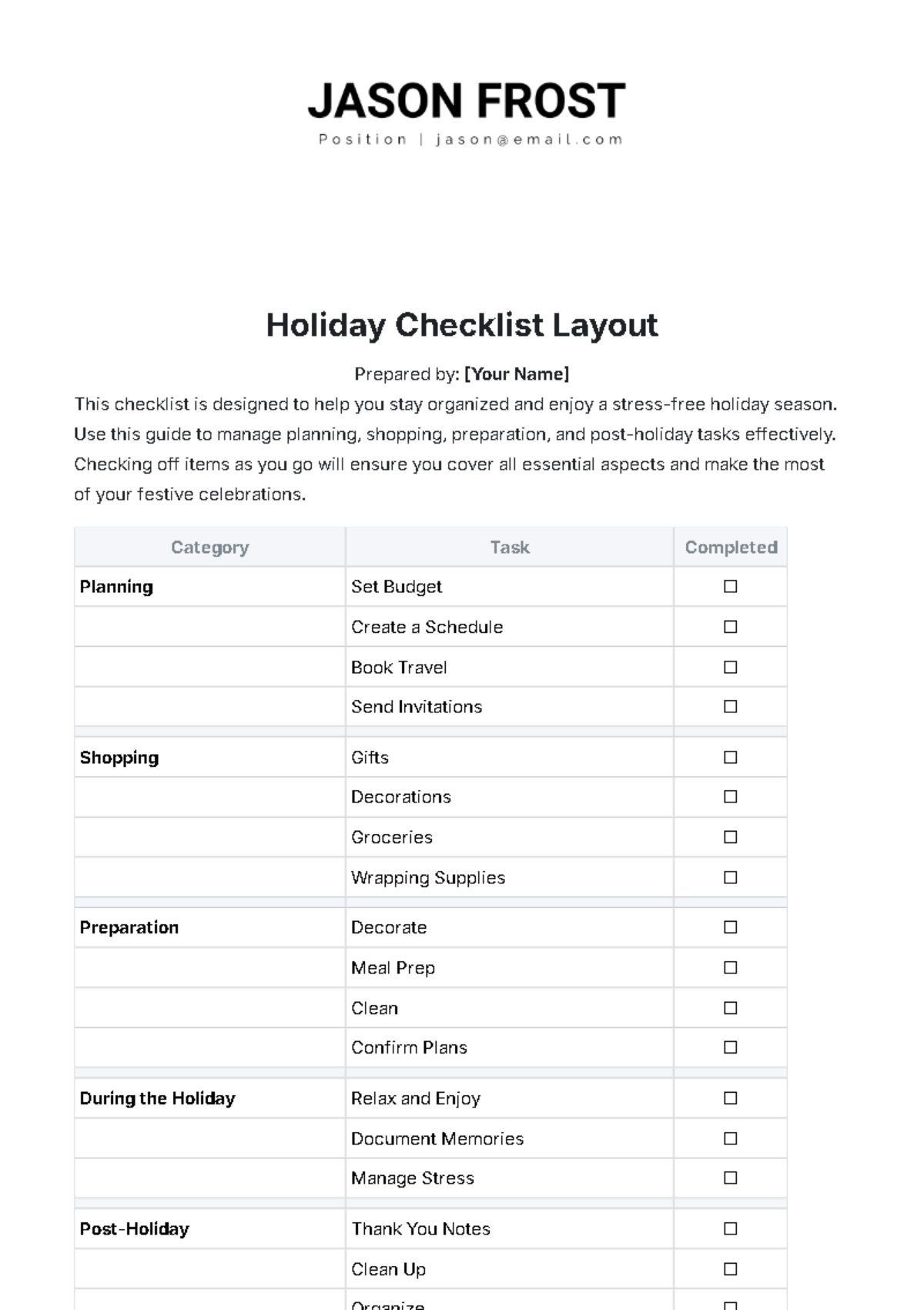

Electrical Safety

Wiring and Cables

All wires and cables are in good condition and properly grounded.

Electrical Panels

Electrical panels are accessible, clearly labeled, and have a disconnect switch for maintenance.

Mechanical Safety

Moving Parts

All moving parts such as gears and belts are properly shielded.

Safety interlocks are in place to prevent machine operation during maintenance.

Vibration and Noise

Vibration levels are within acceptable limits.

Noise is adequately controlled to prevent hearing damage.

Operational Safety

Control Systems

Machine controls are clearly labeled and functioning properly.

Systems prevent unauthorized machine operation.

Maintenance and Inspection Records

Regular maintenance and inspection records are maintained and up-to-date.

Procedures for reporting and fixing faults are established.

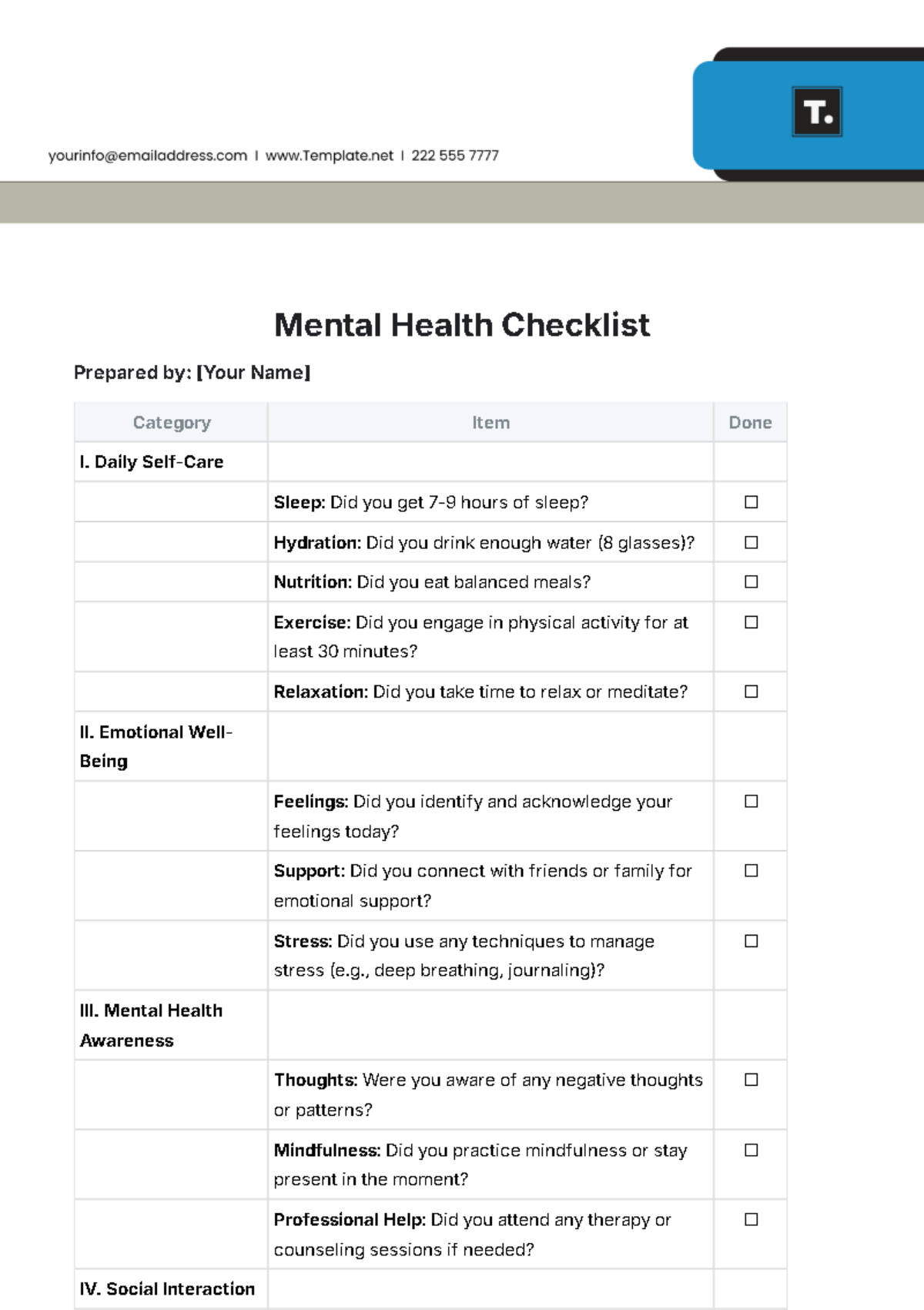

Ergonomics and Environmental Safety

Operator Comfort

Machines are designed for comfortable operation, minimizing strain.

Controls and displays are within easy reach and view.

Work Environment

Adequate lighting is provided in the work area.

The work area is clean, organized, and free of clutter.

Personal Protective Equipment (PPE)

PPE Availability

Appropriate personal protective equipment is provided and accessible.

Training on the correct use of PPE is conducted.

Training and Awareness

Operator Training

Operators are trained in safe machine operation.

Ongoing safety training and awareness programs are in place.

Reporting and Emergency Procedures

Incident Reporting

Clear procedures for reporting safety incidents are established.

Employees are trained in emergency response procedures.