Free Equipment Incident Report

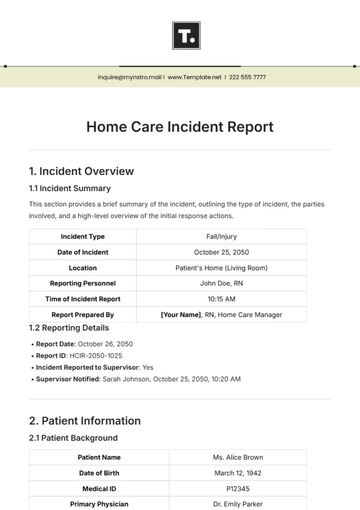

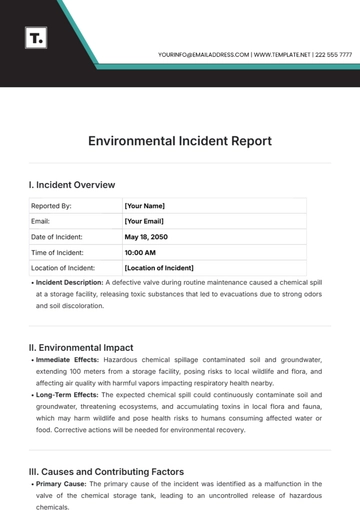

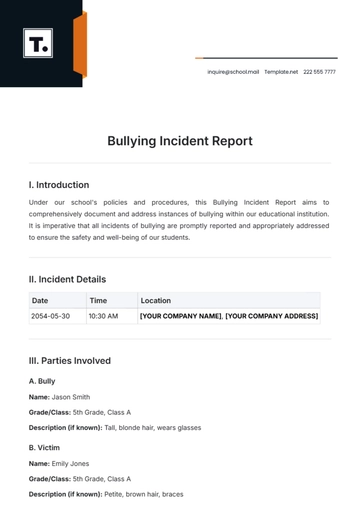

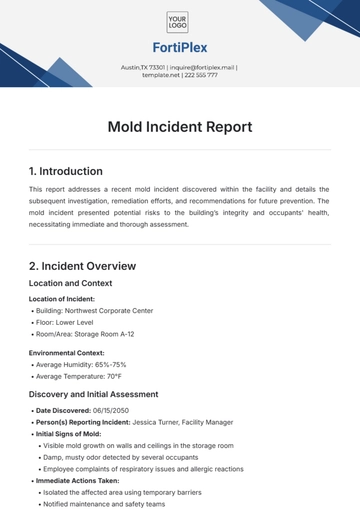

I. Incident Overview

Reported By: [Your Name]

Incident Report Number: 2050-001

Date of Report: May 20, 2050

Time of Report: 10:30 AM

Company Name: [Your Company Name]

Company Address: [Your Company Address]

II. Equipment Involved

Hydraulic Press Machine

Make/Model: Acme 5000

Serial Number: HP-12345

Manufacturer: Acme Machinery Co.

Description: The hydraulic press machine is used for stamping metal components in the manufacturing process of automotive parts. It consists of a hydraulic arm and a stamping mold.

III. Incident Details

On May 20, 2050, at approximately 10:30 AM, an incident occurred involving a hydraulic press machine. The incident took place on the manufacturing floor of Building 12. The equipment was being used to stamp metal components for automotive parts production.

IV. Description of Incident

During the operation of the hydraulic press machine, the operator noticed an unusual grinding noise emanating from the machine. Before the issue could be addressed, the press malfunctioned, causing the hydraulic arm to collapse unexpectedly. As a result, the metal stamping mold dislodged and fell onto the operator's foot.

V. Injuries/Damage

The operator sustained a moderate injury to the right foot, experiencing bruising and swelling. Immediate first aid was administered on-site, and the operator was then transported to the nearest medical facility for further evaluation and treatment. The metal stamping mold incurred minor damage upon impact on the floor.

VI. Witnesses

Witnesses to the incident include Mr. John Smith, the supervisor on duty, and Ms. Emily Jones, a fellow operator.

Their contact information is as follows:

John Smith: +1 (555) 987-6543

Emily Jones: +1 (555) 123-4567

VII. Cause Analysis

Upon investigation, several factors contributed to the incident involving the hydraulic press machine.

Equipment Malfunction: The primary cause of the incident was a malfunction within the hydraulic press machine. The unusual grinding noise reported by the operator indicates a potential mechanical issue that went unaddressed before the incident.

Lack of Maintenance: It appears that the hydraulic press machine may not have received regular maintenance checks, allowing the underlying mechanical issue to escalate and ultimately result in equipment failure.

Operator Awareness: While the operator promptly noticed the abnormal noise and attempted to address it, there may be a need for heightened awareness and training regarding equipment warning signs and safety procedures.

Supervisory Oversight: There is a possibility of insufficient supervisory oversight regarding equipment maintenance and operator safety protocols. A more proactive approach to monitoring equipment conditions and ensuring adherence to safety guidelines could have mitigated the risk of the incident.

VIII. Actions Taken

Upon the occurrence of the incident, emergency services were immediately contacted, and the manufacturing floor was evacuated to ensure the safety of all personnel. The injured operator received prompt medical attention, and the affected area was secured to prevent further accidents. Additionally, the hydraulic press machine was shut down and tagged out of service for inspection and repair.

IX. Recommendations

To prevent similar incidents in the future, it is recommended that regular maintenance checks be conducted on all machinery, including hydraulic press machines, to identify and address any potential malfunctions proactively. Furthermore, additional training sessions should be organized for operators to enhance their awareness of equipment safety protocols and procedures.

X. Conclusion

The incident involving the hydraulic press machine on May 20, 2050, underscores the critical importance of prioritizing equipment safety within our manufacturing facility. While prompt action was taken to address the immediate aftermath of the incident, we must implement comprehensive measures to prevent similar occurrences in the future. By conducting thorough inspections, providing ongoing personnel training, and reinforcing adherence to safety protocols, we can mitigate risks and uphold a safe working environment for all employees. Moving forward, I will continue to collaborate with relevant stakeholders to enact necessary changes and ensure the continued safety and well-being of our workforce.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Introducing the Equipment Incident Report Template, exclusively crafted by Template.net. Swiftly address workplace mishaps with this editable and customizable gem. Tailor it to your specific needs effortlessly. Need more? It's also editable in our AI Editor too, ensuring seamless adaptation to your evolving requirements. Simplify incident documentation and streamline your processes today.

You may also like

- Sales Report

- Daily Report

- Project Report

- Business Report

- Weekly Report

- Incident Report

- Annual Report

- Report Layout

- Report Design

- Progress Report

- Marketing Report

- Company Report

- Monthly Report

- Audit Report

- Status Report

- School Report

- Reports Hr

- Management Report

- Project Status Report

- Handover Report

- Health And Safety Report

- Restaurant Report

- Construction Report

- Research Report

- Evaluation Report

- Investigation Report

- Employee Report

- Advertising Report

- Weekly Status Report

- Project Management Report

- Finance Report

- Service Report

- Technical Report

- Meeting Report

- Quarterly Report

- Inspection Report

- Medical Report

- Test Report

- Summary Report

- Inventory Report

- Valuation Report

- Operations Report

- Payroll Report

- Training Report

- Job Report

- Case Report

- Performance Report

- Board Report

- Internal Audit Report

- Student Report

- Monthly Management Report

- Small Business Report

- Accident Report

- Call Center Report

- Activity Report

- IT and Software Report

- Internship Report

- Visit Report

- Product Report

- Book Report

- Property Report

- Recruitment Report

- University Report

- Event Report

- SEO Report

- Conference Report

- Narrative Report

- Nursing Home Report

- Preschool Report

- Call Report

- Customer Report

- Employee Incident Report

- Accomplishment Report

- Social Media Report

- Work From Home Report

- Security Report

- Damage Report

- Quality Report

- Internal Report

- Nurse Report

- Real Estate Report

- Hotel Report

- Equipment Report

- Credit Report

- Field Report

- Non Profit Report

- Maintenance Report

- News Report

- Survey Report

- Executive Report

- Law Firm Report

- Advertising Agency Report

- Interior Design Report

- Travel Agency Report

- Stock Report

- Salon Report

- Bug Report

- Workplace Report

- Action Report

- Investor Report

- Cleaning Services Report

- Consulting Report

- Freelancer Report

- Site Visit Report

- Trip Report

- Classroom Observation Report

- Vehicle Report

- Final Report

- Software Report