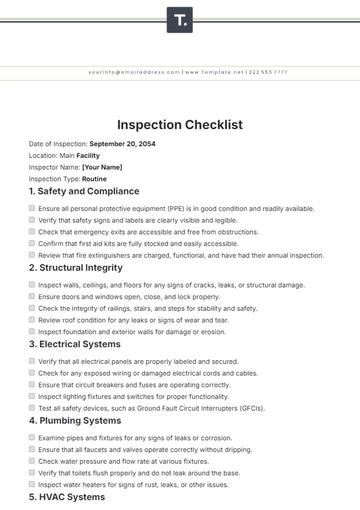

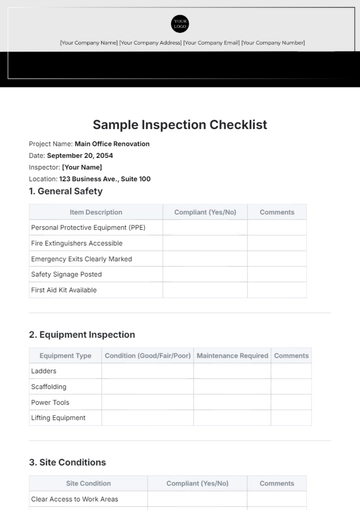

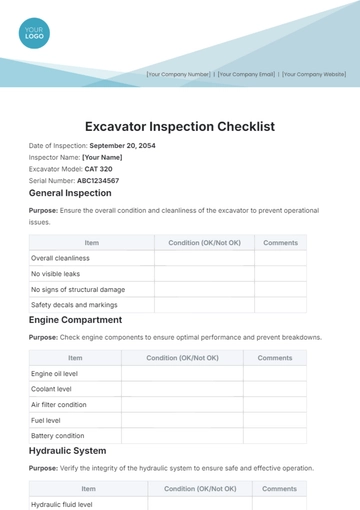

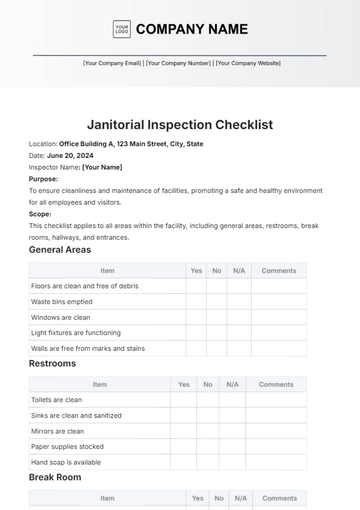

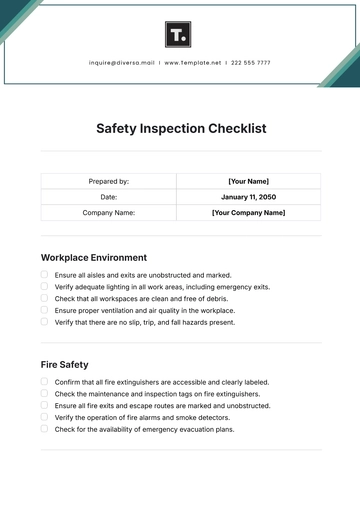

Free Site Safety Inspection Checklist

This Site Safety Inspection Checklist is designed to ensure a comprehensive evaluation of safety practices on site. Use this checklist to systematically assess PPE, worksite conditions, equipment, emergency procedures, hazard identification, and compliance. Complete each item and address any identified issues promptly.

Inspection Date: | |

Inspector Name: | |

Weather Conditions: | |

Project Phase: | |

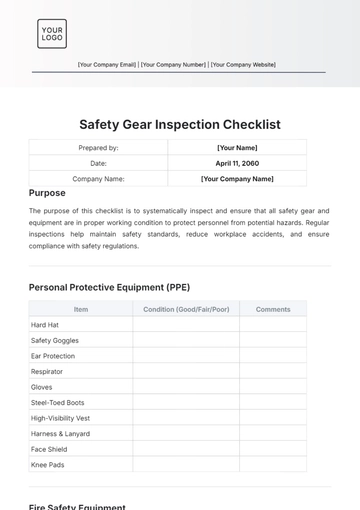

I. Personal Protective Equipment (PPE)

Hard Hats: All workers are wearing appropriate hard hats.

Safety Glasses: Safety glasses are being used in all required areas.

Gloves: Gloves provided and used by workers handling materials.

Hearing Protection: Hearing protection is used in areas with high noise levels.

Safety Boots: All workers are wearing steel-toe safety boots.

High-Visibility Clothing: High-visibility vests are worn by all site personnel.

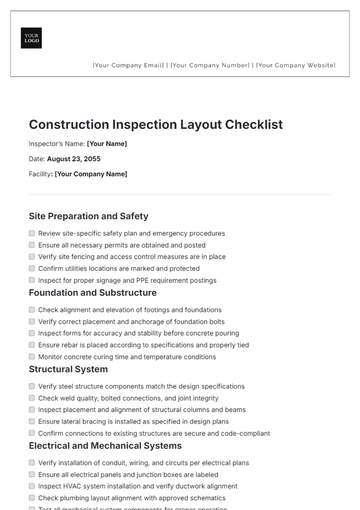

II. Worksite Conditions

Cleanliness: Site is free from unnecessary debris; pathways and work areas are regularly swept.

Material Storage: Materials are stored on stable surfaces; hazardous materials are kept in designated storage areas with proper labeling.

Access and Egress: Walkways, stairs, and emergency exits are unobstructed and well-marked; ladders are secured and in good condition.

Signage: All safety and hazard signs are clearly visible and maintained; directional and informational signs are correct and in place.

Lighting: Adequate lighting is provided in all work and access areas; emergency lighting is operational.

Waste Management: Waste and recycling containers are available and used properly; site has a plan for regular removal and disposal of waste.

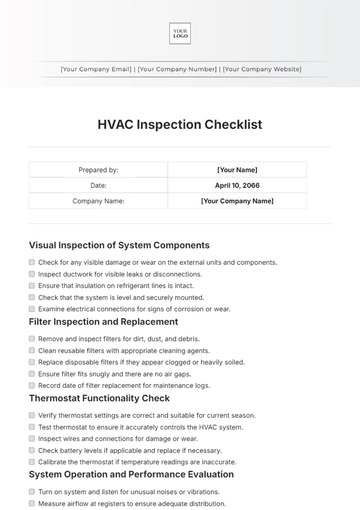

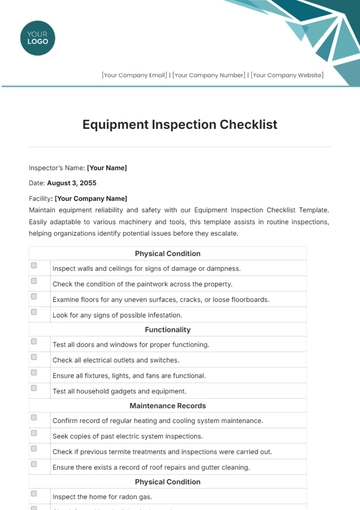

III. Equipment Safety

Inspection Records: Equipment inspection records are up-to-date and available.

Condition: Machinery is in good working condition; no visible damage.

Maintenance: Maintenance logs indicate regular servicing of equipment.

Safe Operation: Equipment operators have completed required safety training.

IV. Emergency Procedures

Emergency Plan: Emergency plan is posted at site entrance and communicated to workers.

First Aid Kits: First aid kits are available and stocked with necessary supplies.

Fire Extinguishers: Fire extinguishers are accessible, checked monthly, and tagged.

Emergency Contacts: Emergency contact numbers are posted near telephones.

V. Hazard Identification

Chemical Hazards: Chemicals are stored in proper containers; SDS are available and easily accessible; spill containment measures are in place.

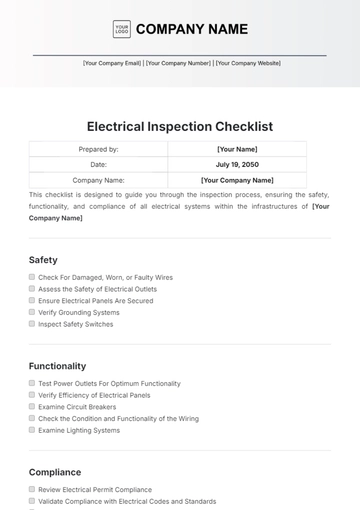

Electrical Hazards: Electrical panels are properly labeled and accessible; extension cords are in good condition and not overloaded; GFCIs are used where required.

Fall Hazards: Guardrails and safety nets are installed where necessary; personal fall arrest systems are inspected and used correctly; scaffoldings are properly erected and maintained.

Moving Machinery: Machinery and equipment have proper guarding; emergency stop buttons are functional and easily reachable; operators are trained and aware of machinery hazards.

Ergonomic Hazards: Workstations and tasks are designed to minimize strain; proper lifting techniques are promoted; ergonomic assessments are conducted as needed.

Noise Hazards: Noise levels are monitored; hearing protection is available and used; areas with high noise levels are properly marked.

VI. Compliance

Regulatory Standards: Site complies with OSHA regulations, local building codes, and industry-specific safety standards; any recent regulatory changes are integrated.

Company Policies: Safety policies are up-to-date and reflect current practices; all employees are familiar with and adhere to these policies.

Training: Workers have received appropriate training for their tasks; training records are maintained and up-to-date; refresher training is conducted as needed.

Permits and Licenses: All necessary permits and licenses are obtained and current; any required inspections are completed on schedule.

Documentation: Safety documentation, including risk assessments and safety plans, are properly maintained and readily accessible; records of past inspections are reviewed.

Incident Reporting: Procedures for reporting and investigating incidents are in place and followed; incident records are kept and reviewed for patterns and improvements.

VII. Observations and Recommendations

Observations

Recommendations

Action Items

Follow-Up Date

Inspector's Name:

Date:

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Elevate your safety inspections with the Site Safety Inspection Checklist Template from Template.net. This editable and customizable template allows for easy modifications using our AI Editor Tool, ensuring that your checklist perfectly fits your needs. Streamline your safety protocols and ensure compliance with a tool designed for flexibility and efficiency.

You may also like

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

- Risk Assessment Checklist

- Onboarding Checklist

- Quality Checklist

- Compliance Checklist

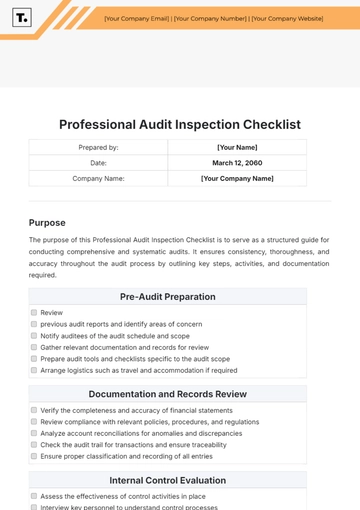

- Audit Checklist

- Registry Checklist

- HR Checklist

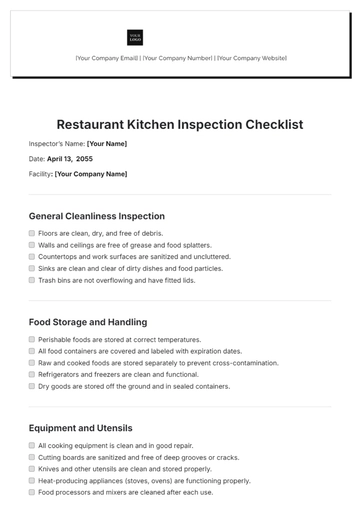

- Restaurant Checklist

- Checklist Layout

- Creative Checklist

- Sales Checklist

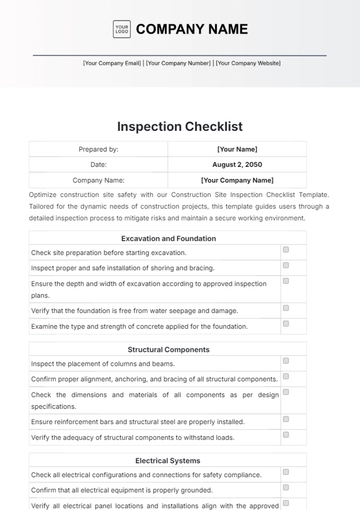

- Construction Checklist

- Task Checklist

- Professional Checklist

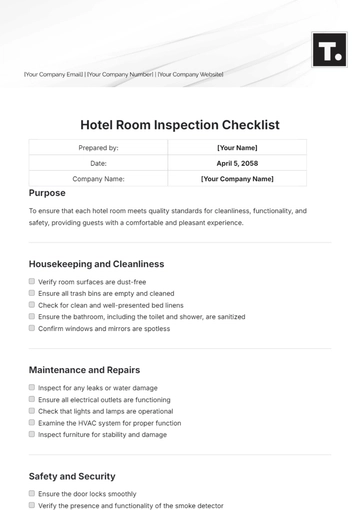

- Hotel Checklist

- Employee Checklist

- Moving Checklist

- Marketing Checklist

- Accounting Checklist

- Camping Checklist

- Packing Checklist

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

- Food Checklist

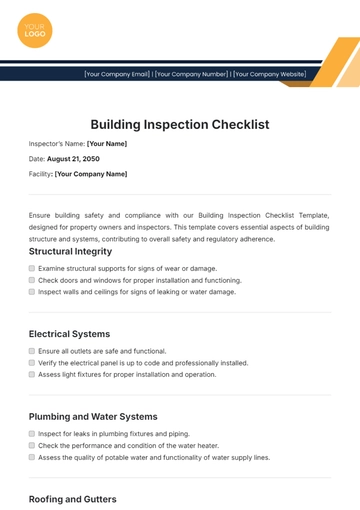

- Home Inspection Checklist

- Advertising Checklist

- Event Checklist

- SEO Checklist

- Assessment Checklist

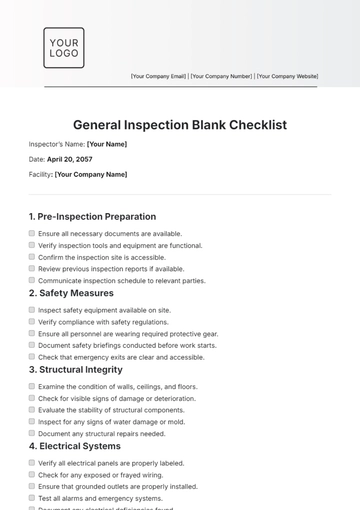

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

- Employee Training Checklist

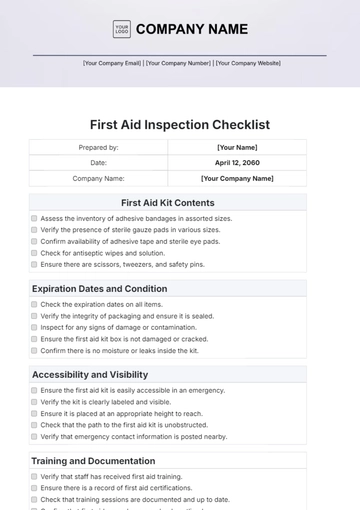

- Medical Checklist

- Safety Checklist

- Site Checklist

- Job Checklist

- Service Checklist

- Nanny Checklist

- Building Checklist

- Work Checklist

- Office Checklist

- Training Checklist

- Website Checklist

- IT and Software Checklist

- Performance Checklist

- Project Checklist

- Startup Checklist

- Education Checklist

- Home Checklist

- School Checklist

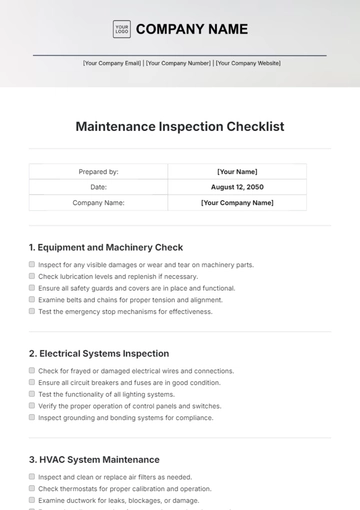

- Maintenance Checklist

- Planning Checklist

- Manager Checklist

- Wedding Checklist

- Vehicle Checklist

- Travel Agency Checklist

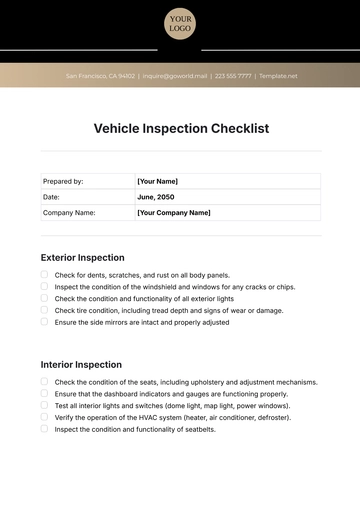

- Vehicle Inspection Checklist

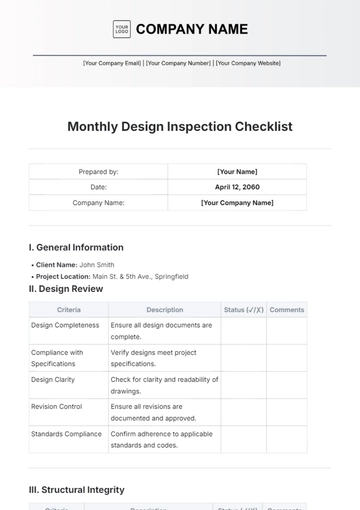

- Interior Design Checklist

- Backpacking Checklist

- Business Checklist

- Legal Checklist

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

- Equipment Checklist

- Trade Show Checklist

- Party Checklist

- Hospital Bag Checklist

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

- Rental Checklist

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

- Work From Home Checklist

- Student Checklist

- Application Checklist