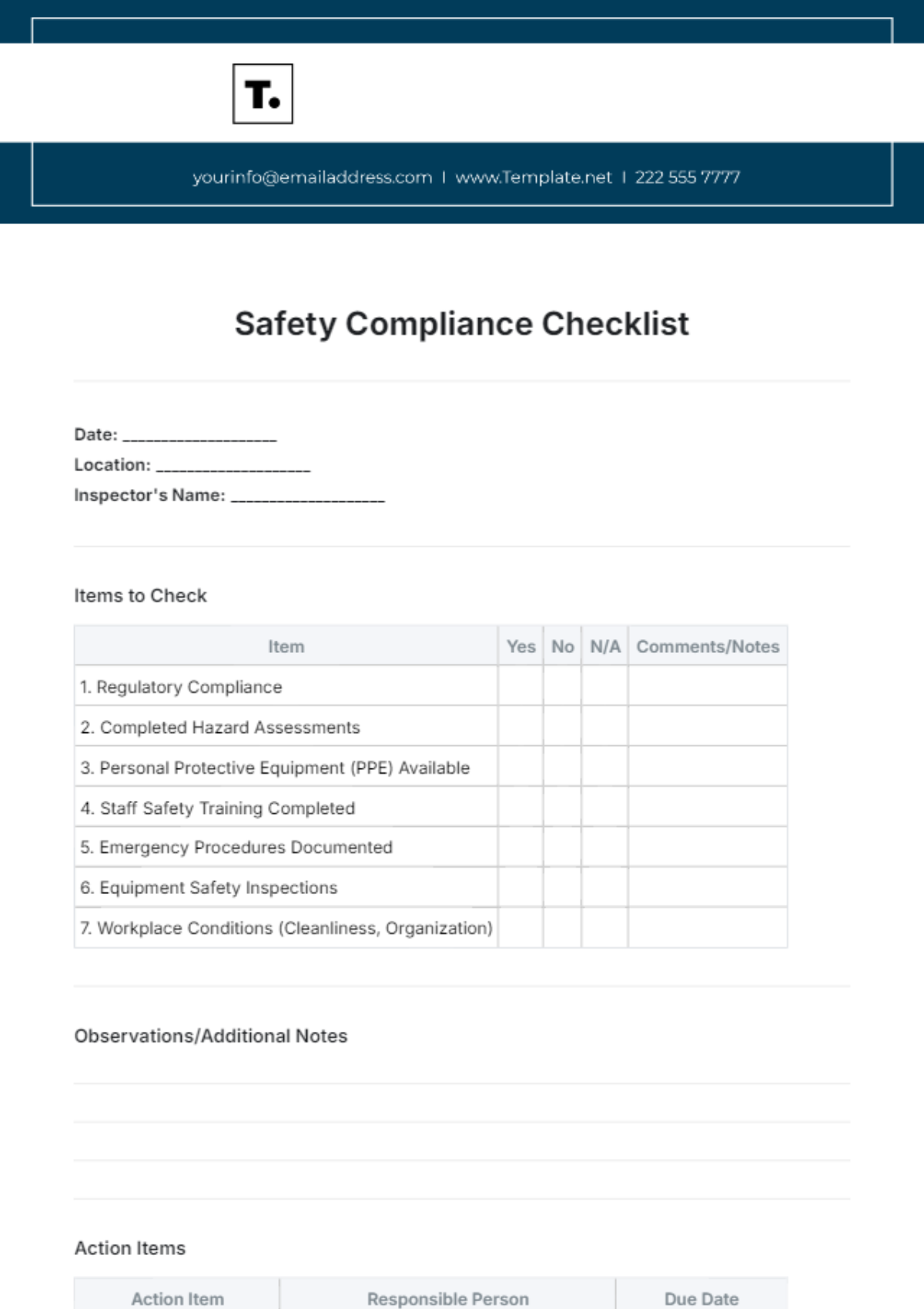

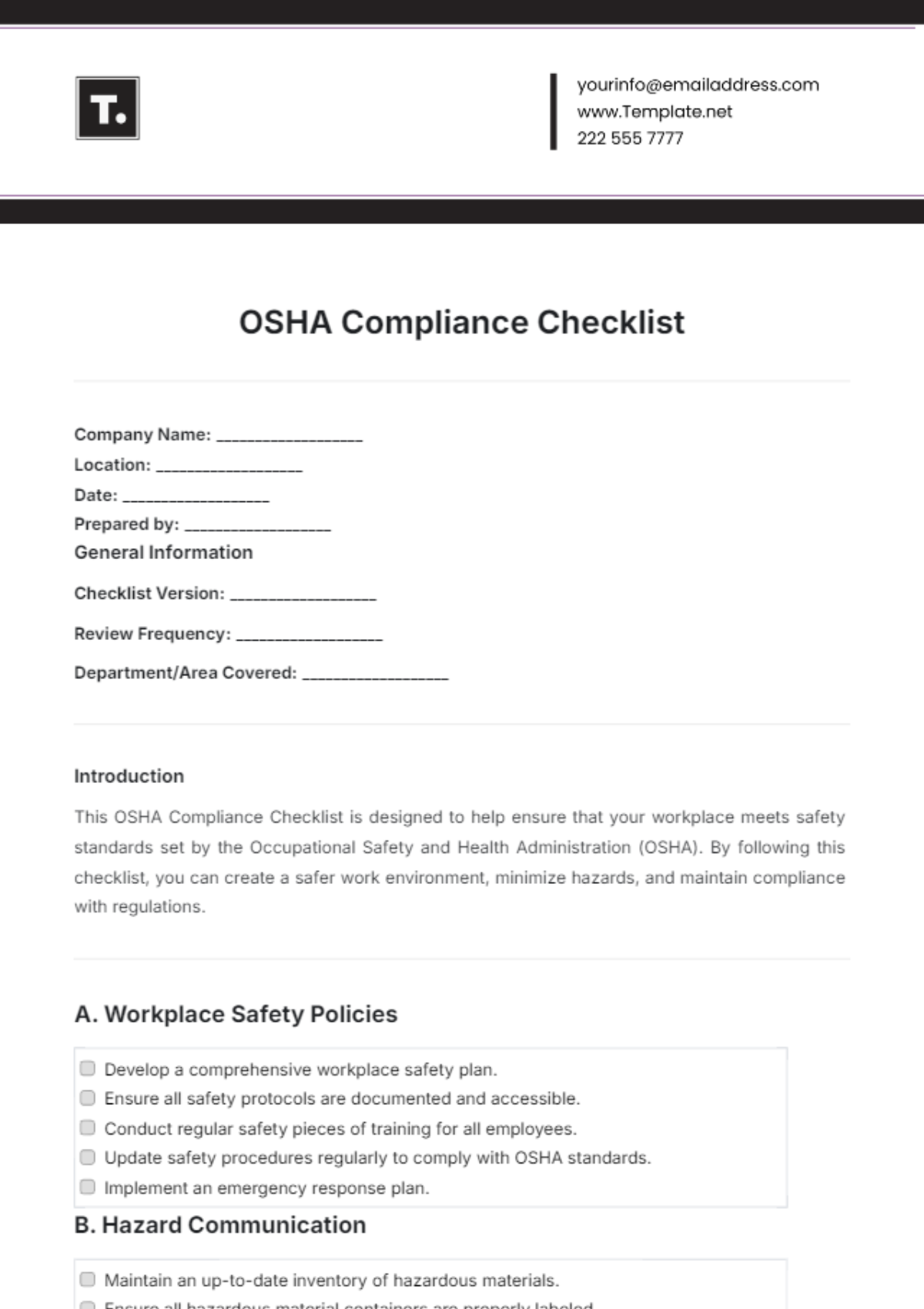

OSHA Compliance Checklist Layout

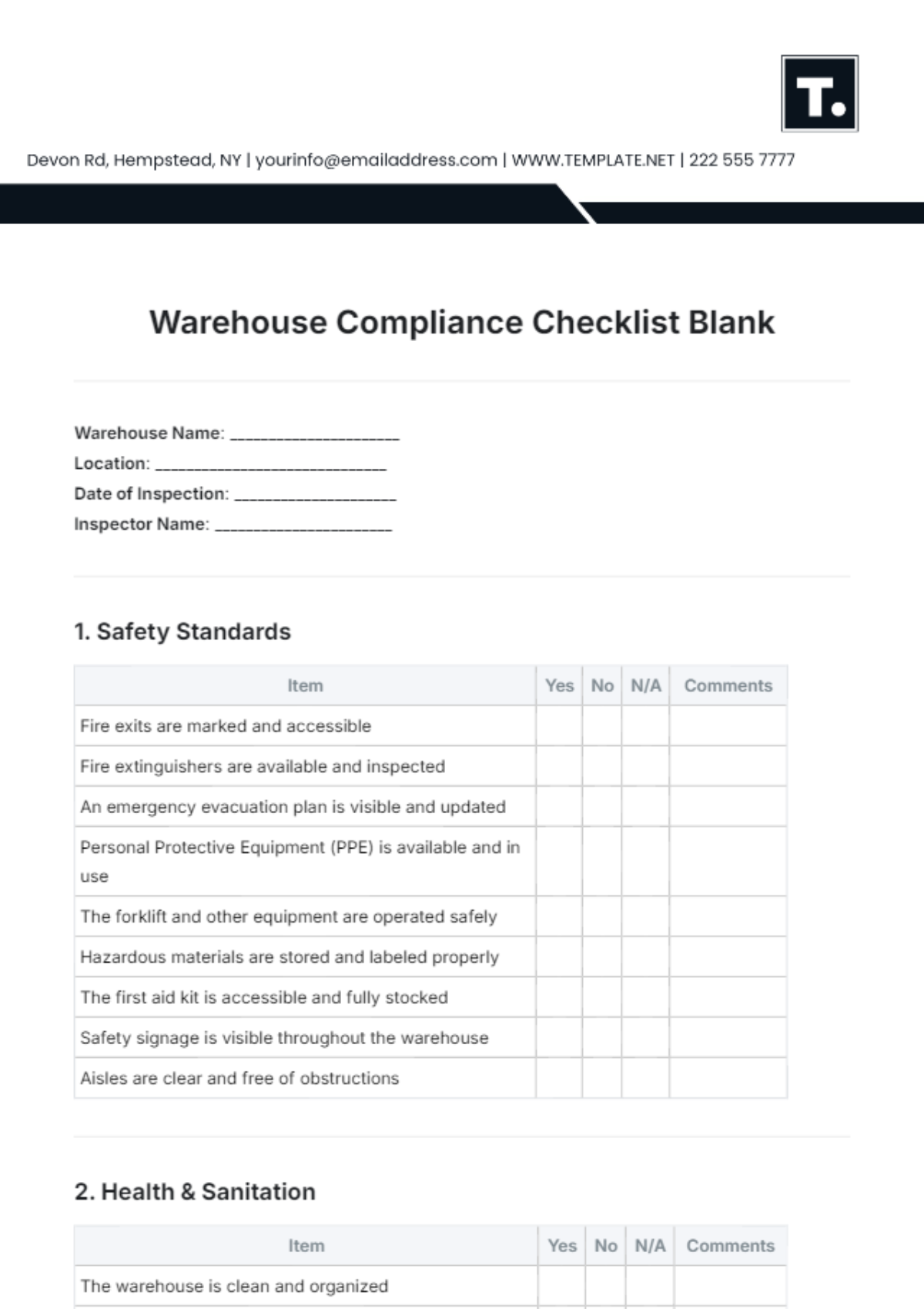

Company Name: ___________________

Location: ___________________

Date: ___________________

Prepared by: ___________________

General Information

Checklist Version: ___________________

Review Frequency: ___________________

Department/Area Covered: ___________________

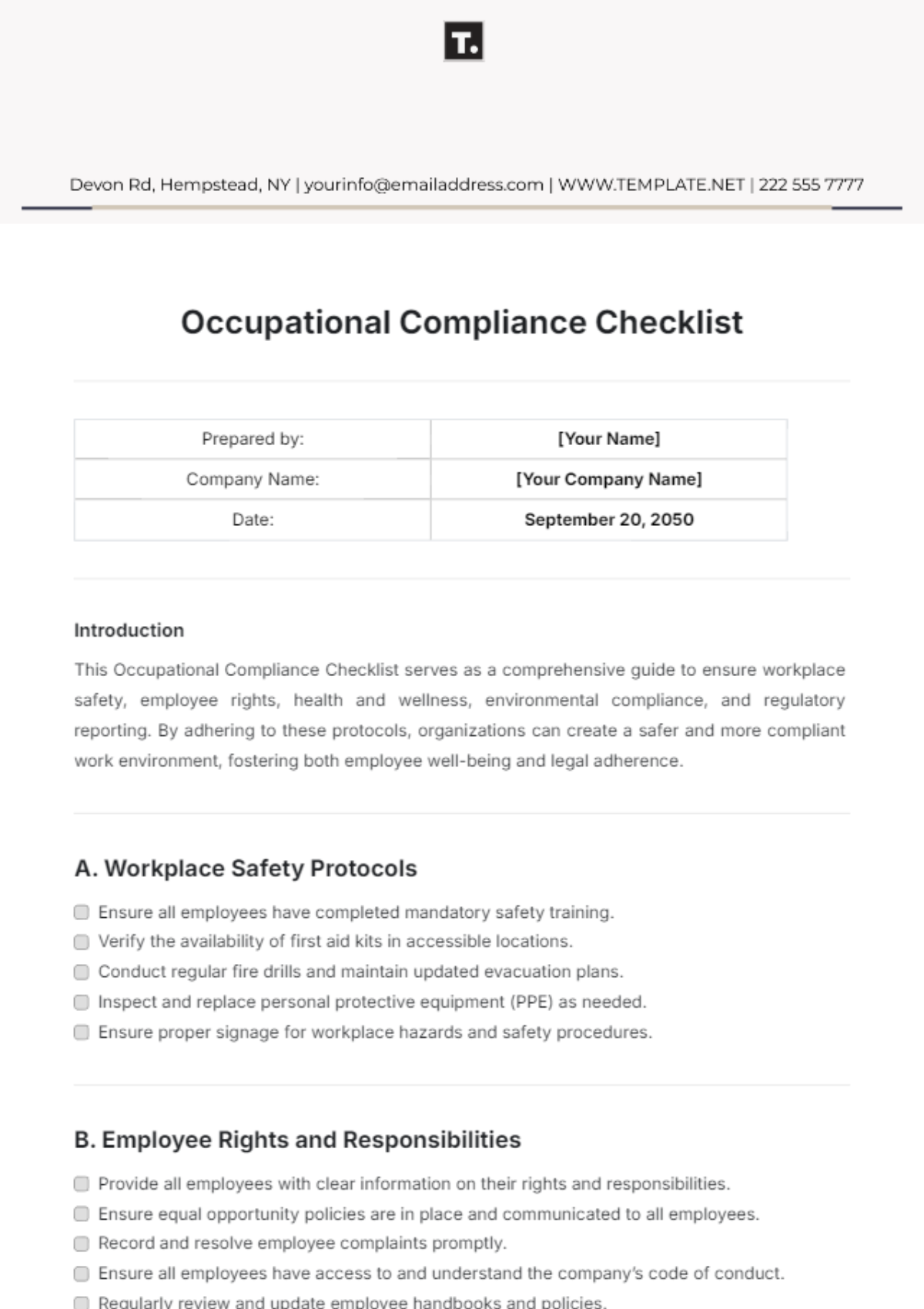

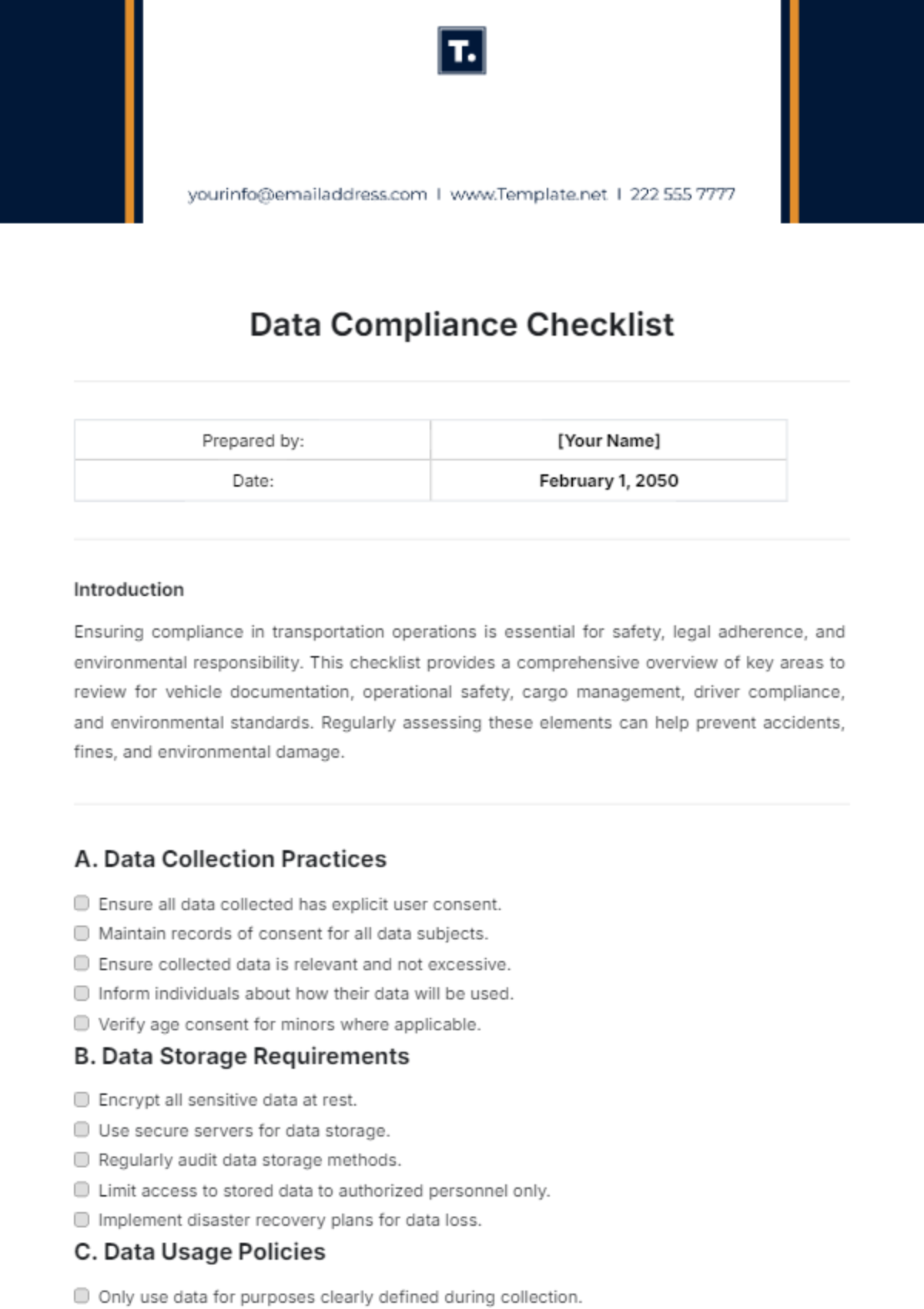

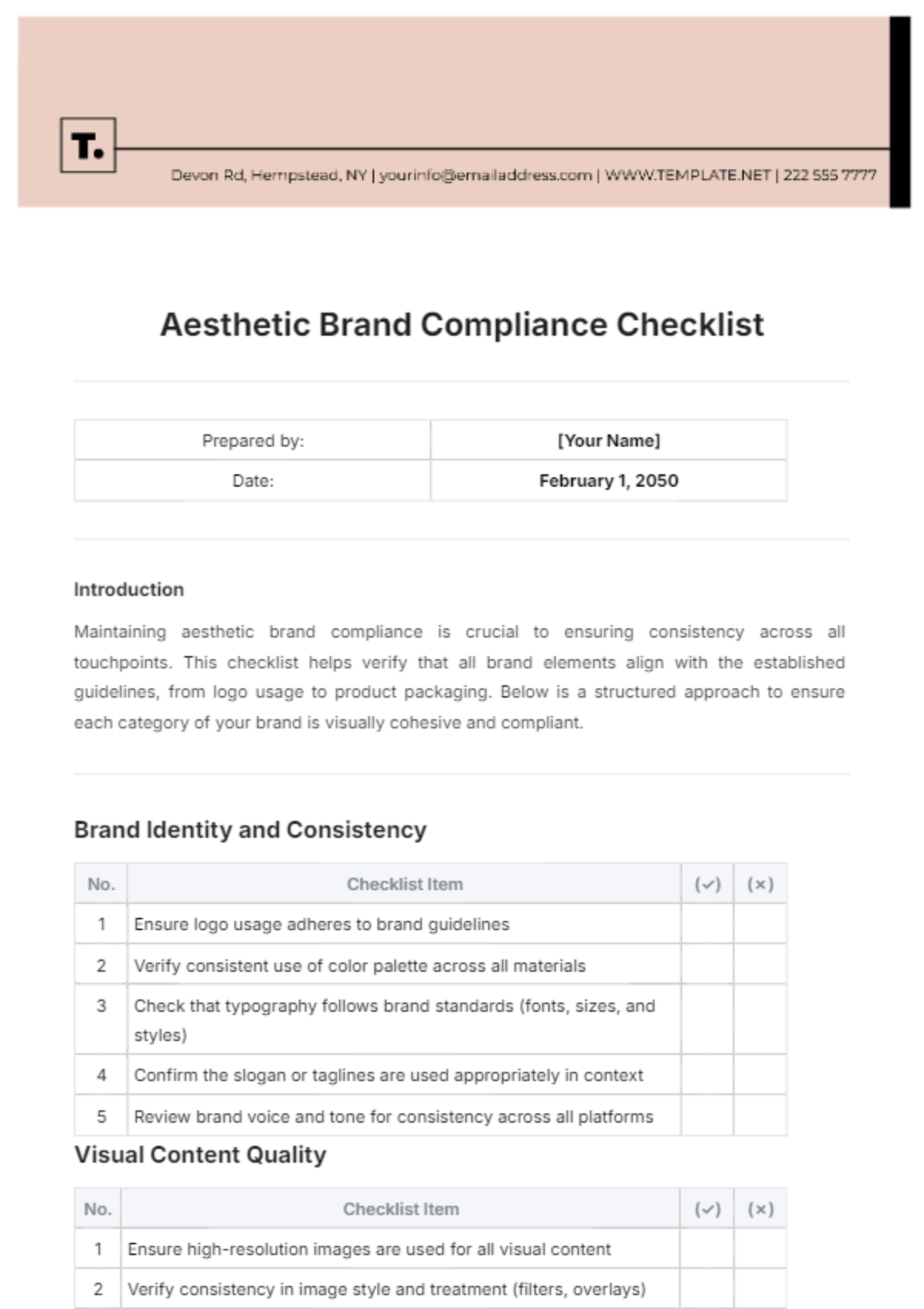

Introduction

This OSHA Compliance Checklist is designed to help ensure that your workplace meets safety standards set by the Occupational Safety and Health Administration (OSHA). By following this checklist, you can create a safer work environment, minimize hazards, and maintain compliance with regulations.

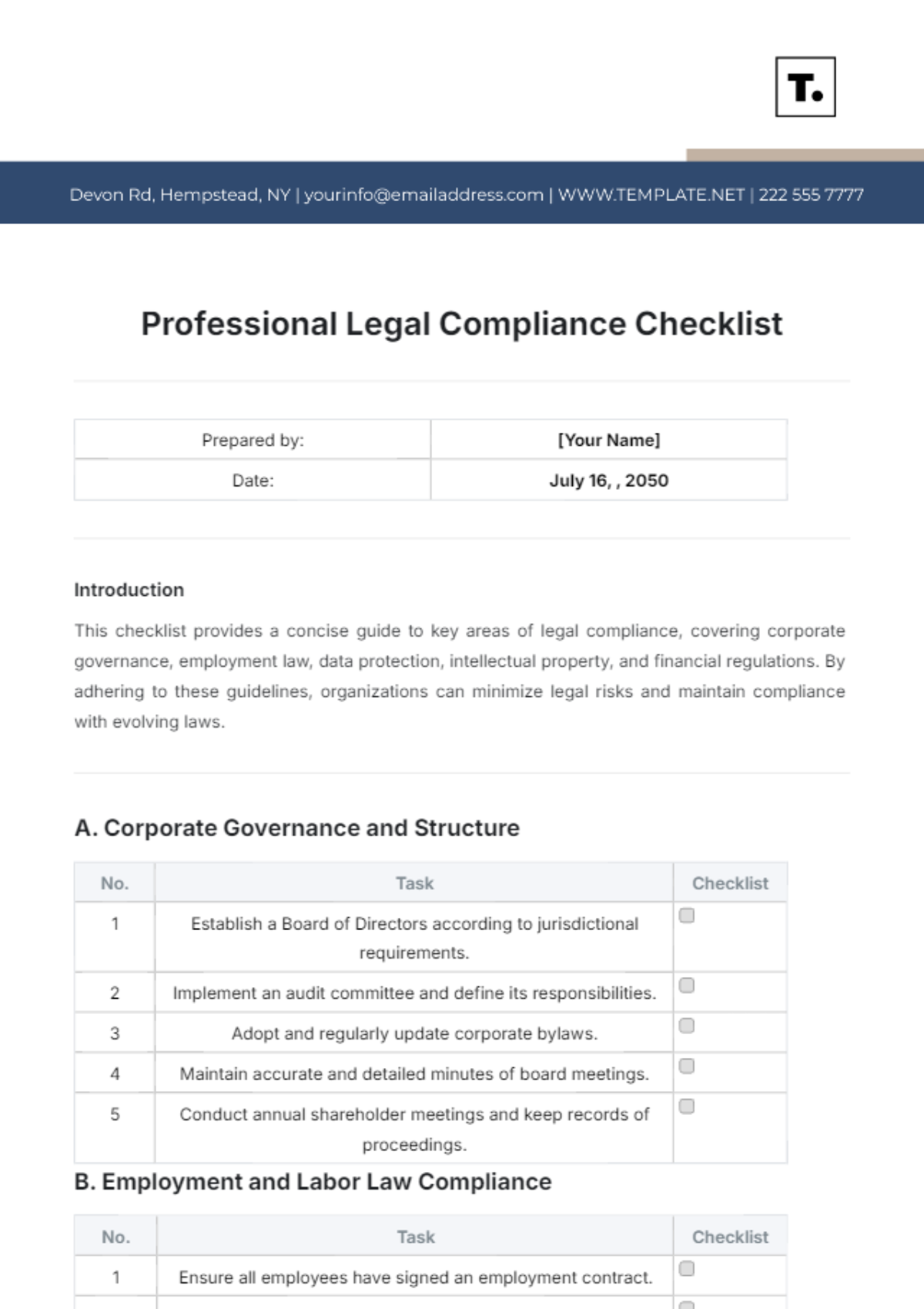

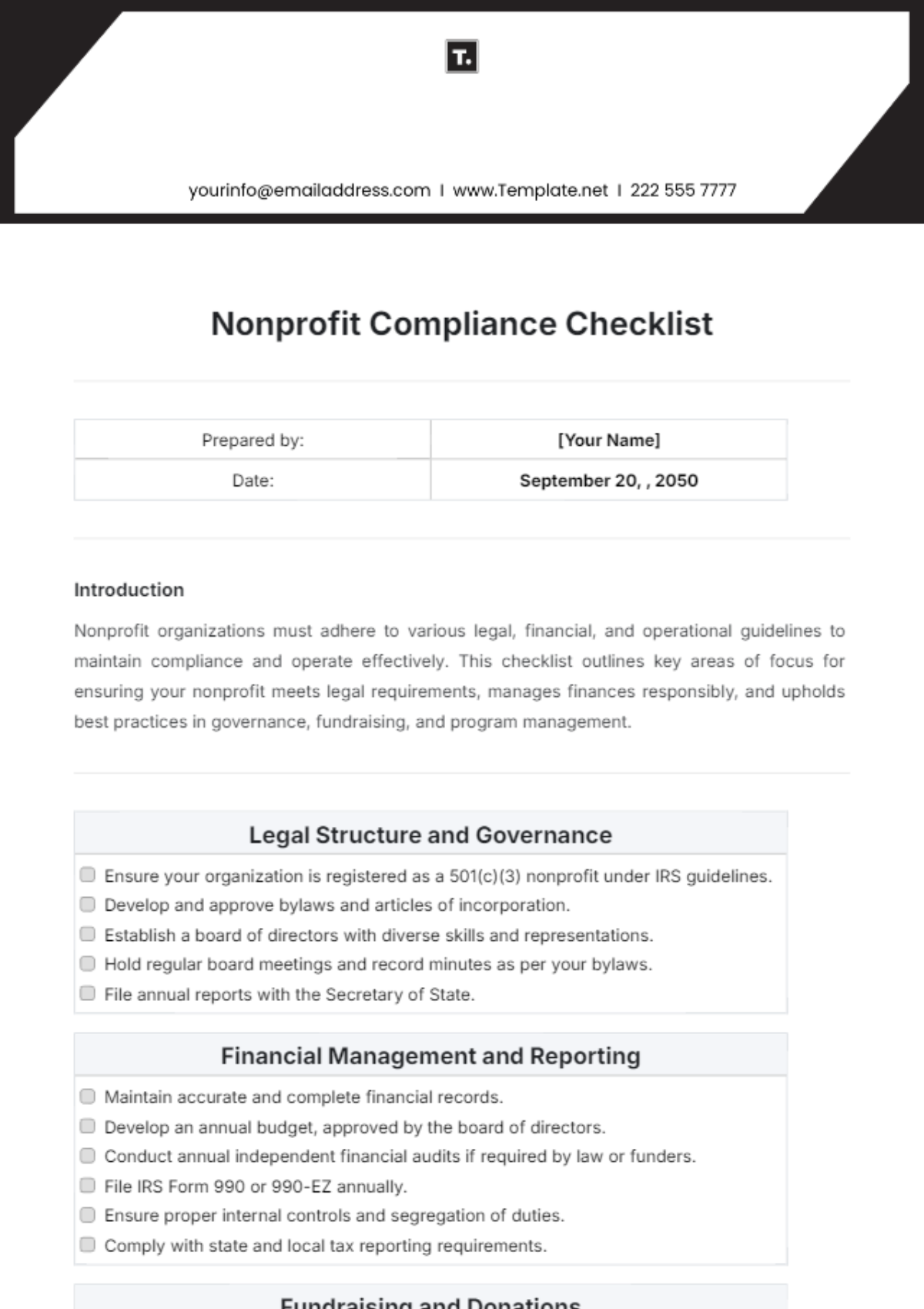

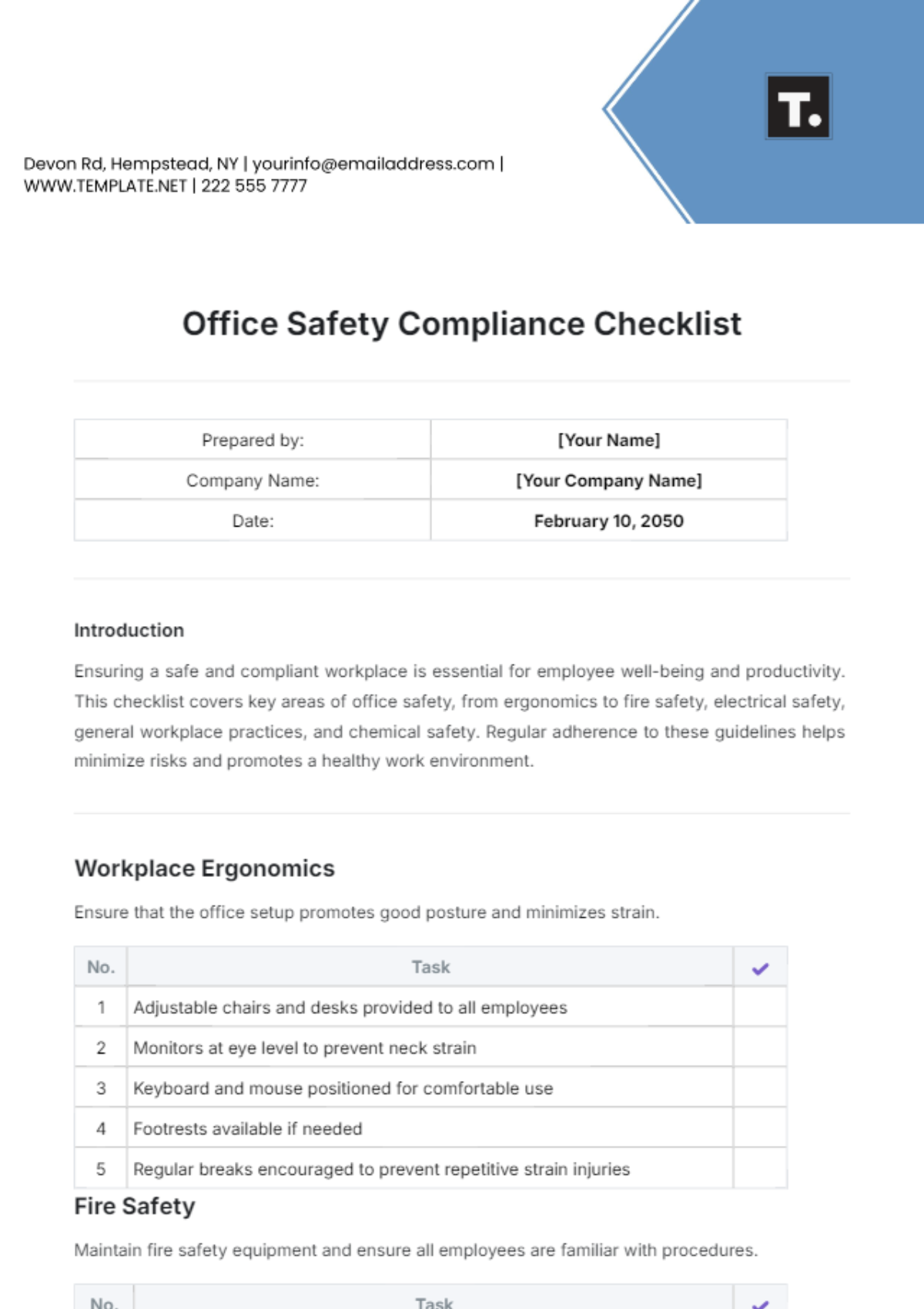

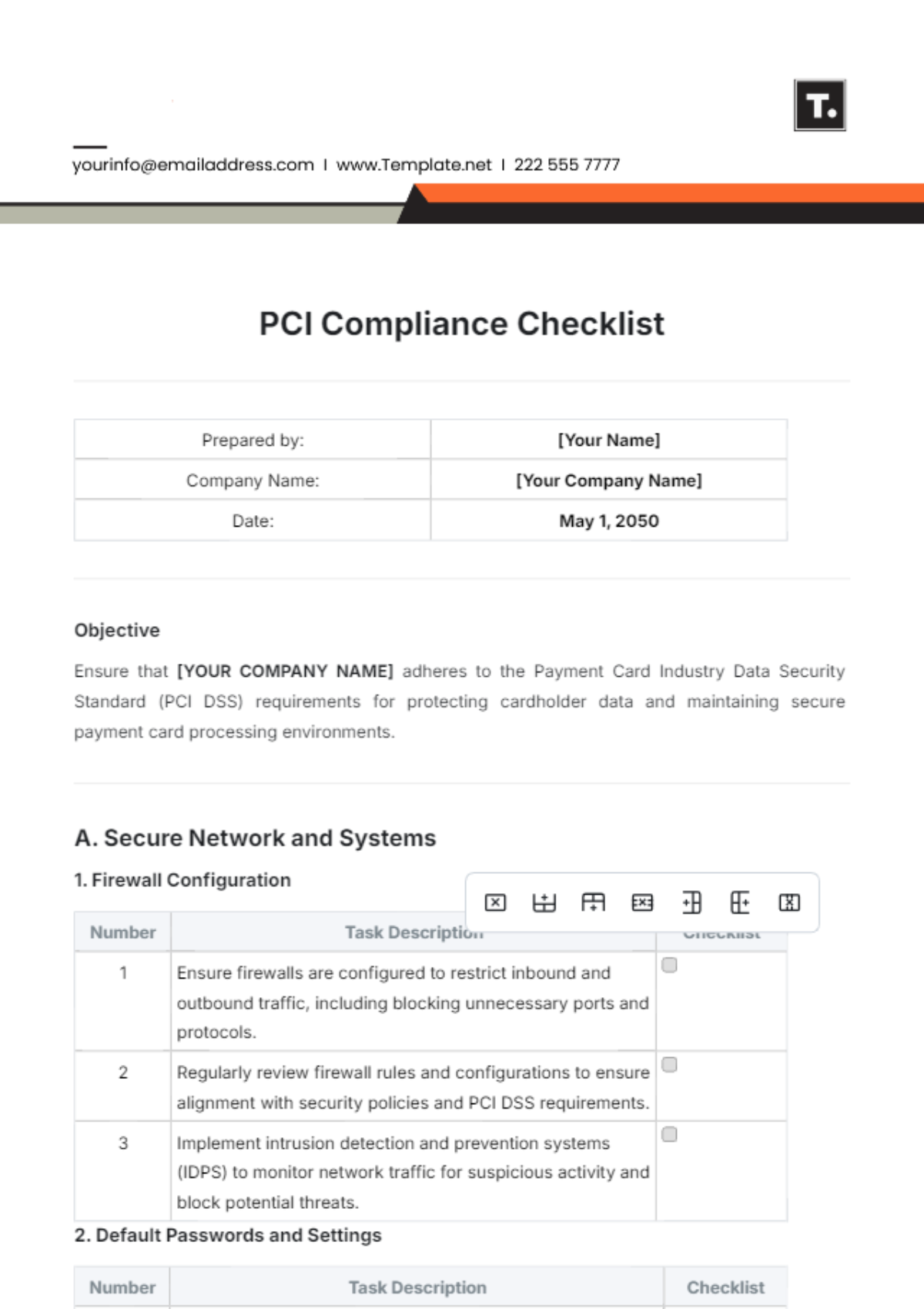

A. Workplace Safety Policies

|

B. Hazard Communication

|

C. Personal Protective Equipment (PPE)

|

D. Recordkeeping and Reporting

|

E. Machine and Equipment Safety

|

Observations/Comments

Sign-Off

Prepared by: ___________________

Reviewed by: ___________________

Date of Review: ___________________