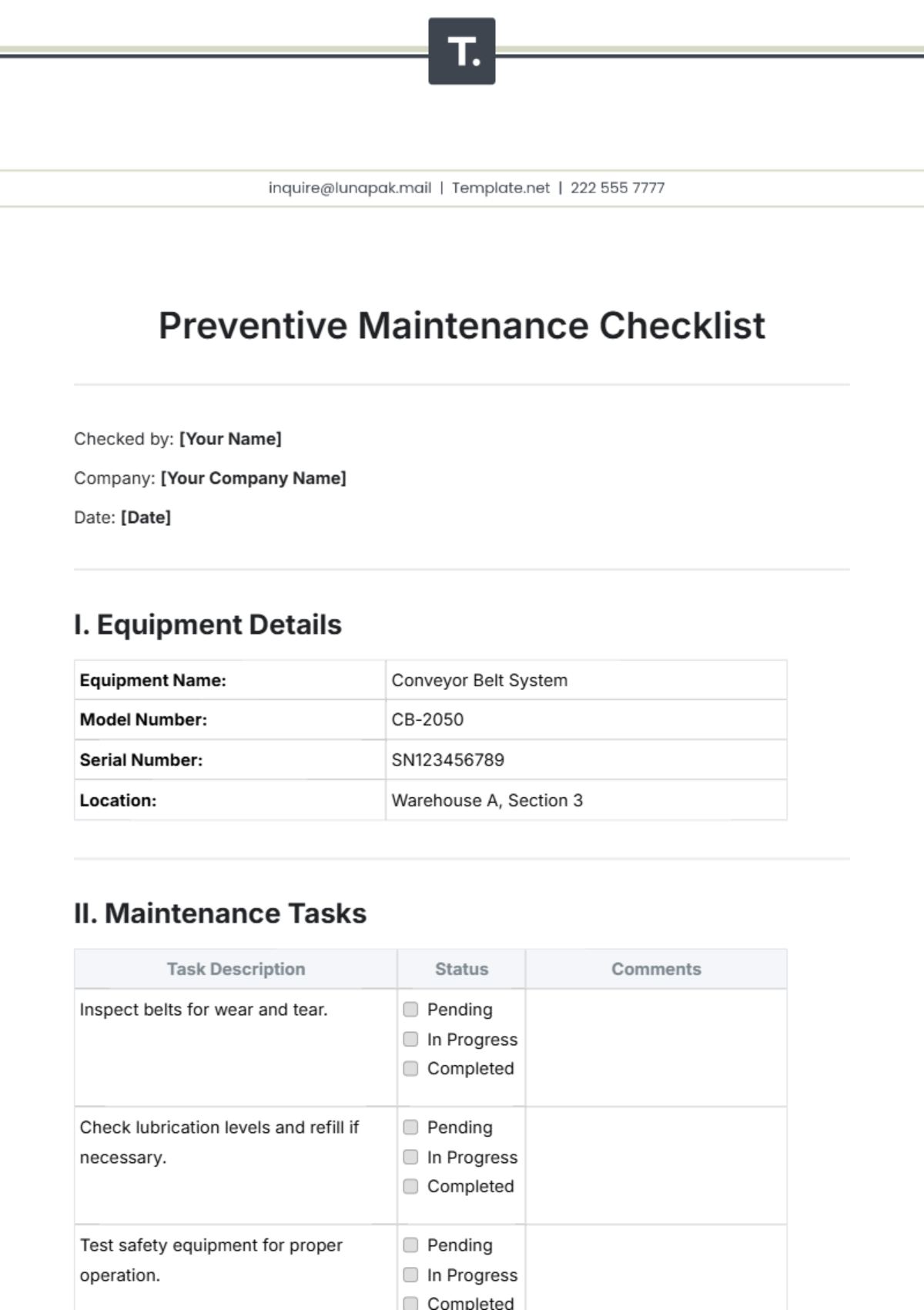

Preventive Maintenance Checklist

Checked by: [Your Name]

Company: [Your Company Name]

Date: [Date]

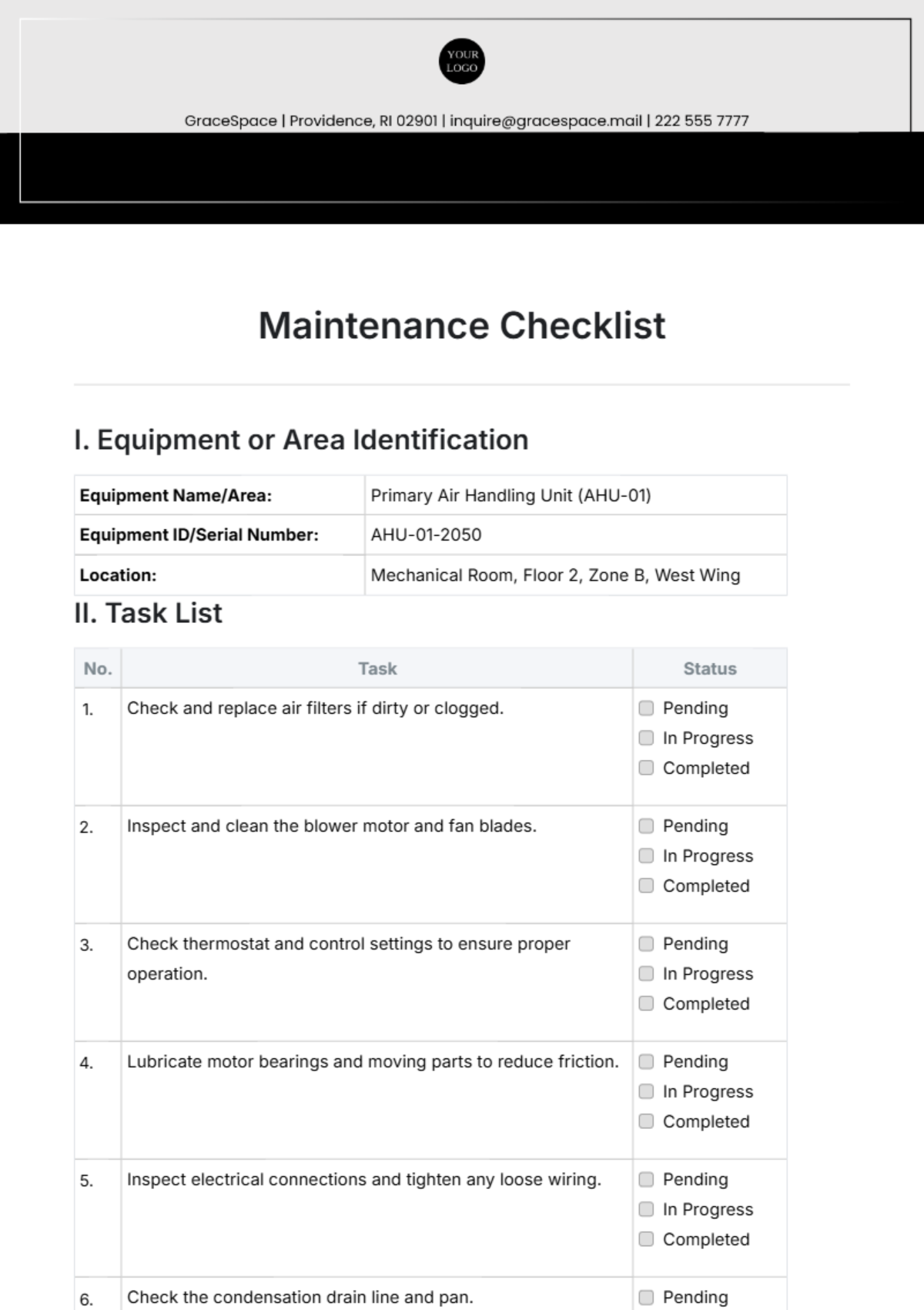

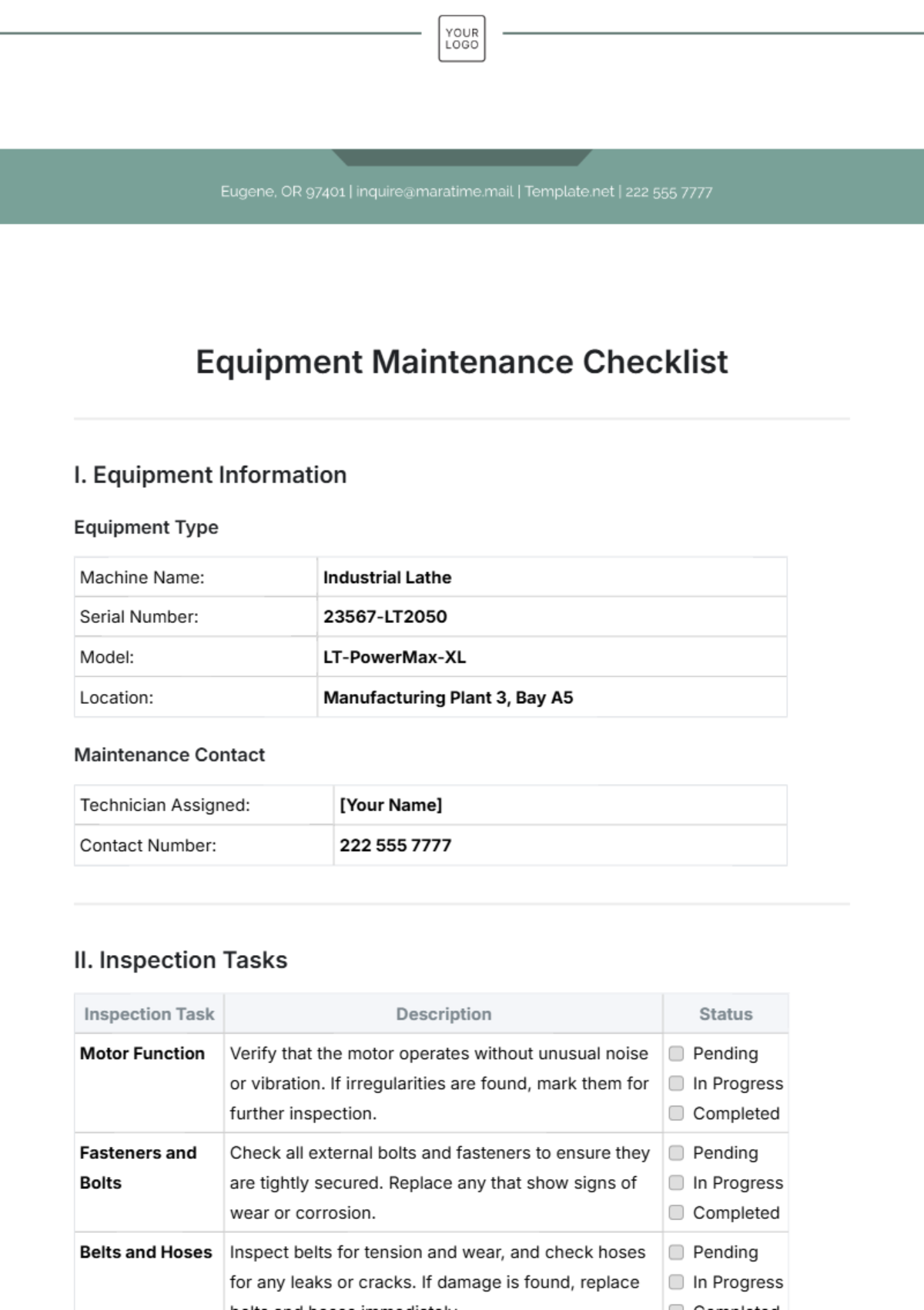

I. Equipment Details

Equipment Name: | Conveyor Belt System |

Model Number: | CB-2050 |

Serial Number: | SN123456789 |

Location: | Warehouse A, Section 3 |

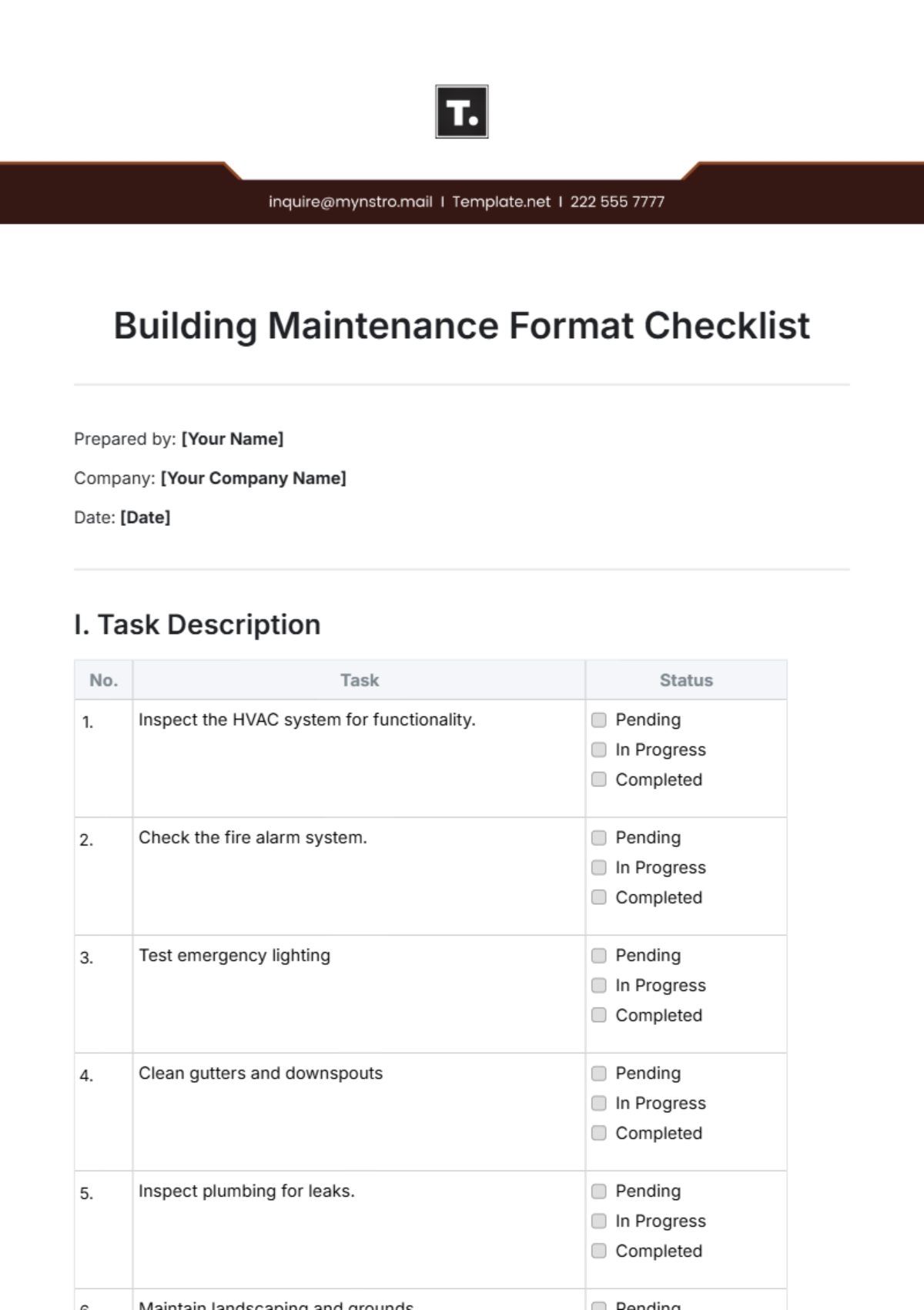

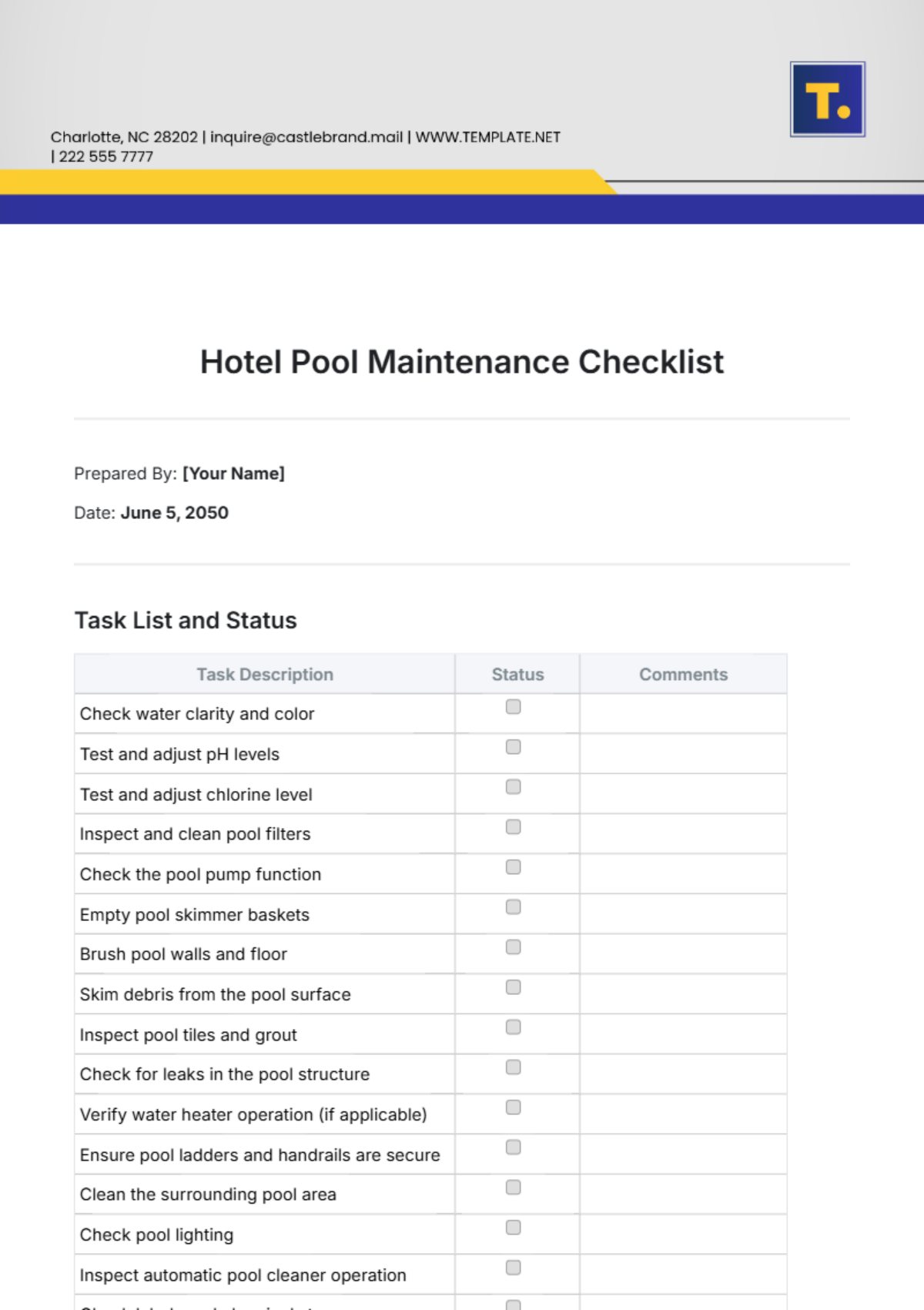

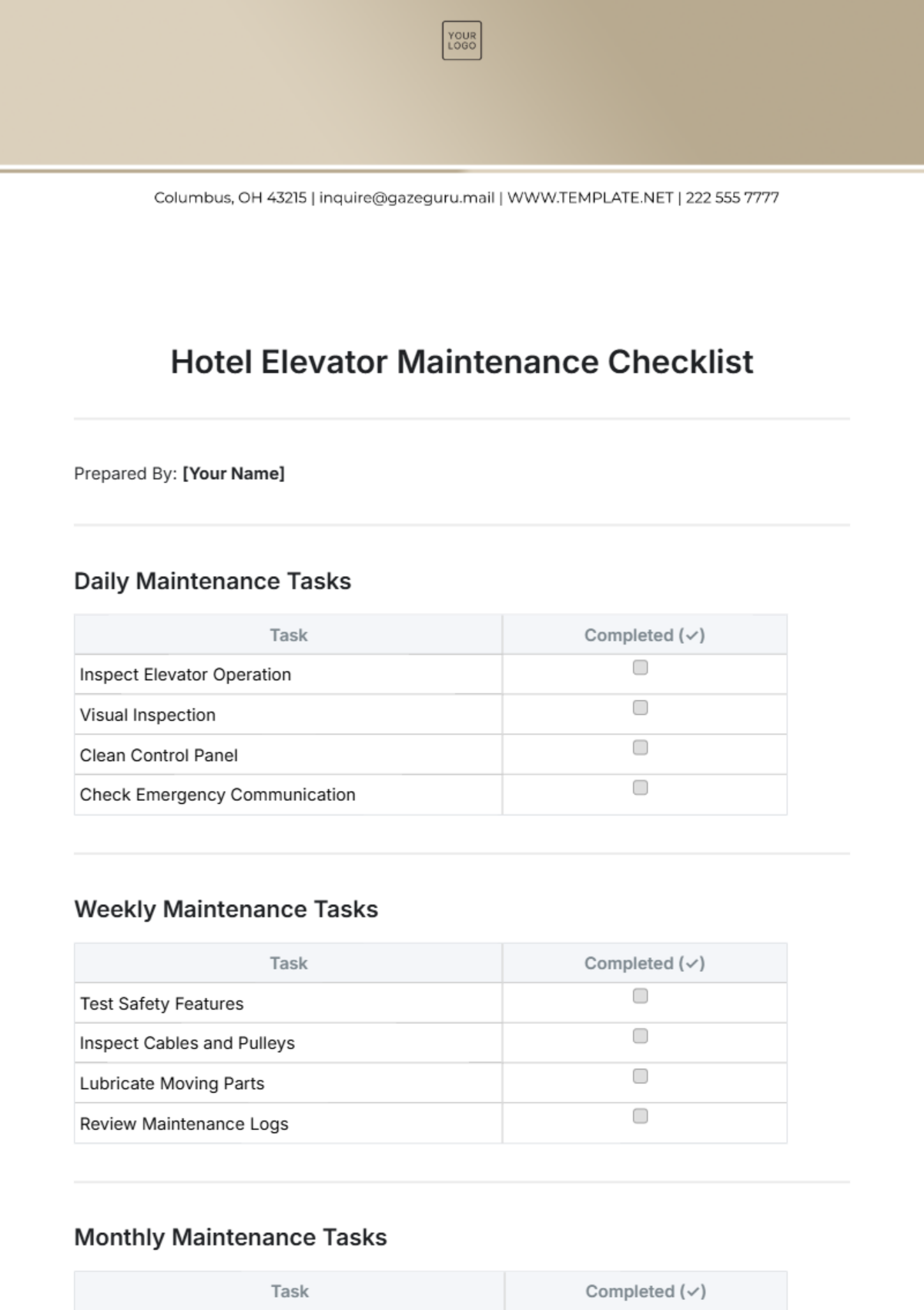

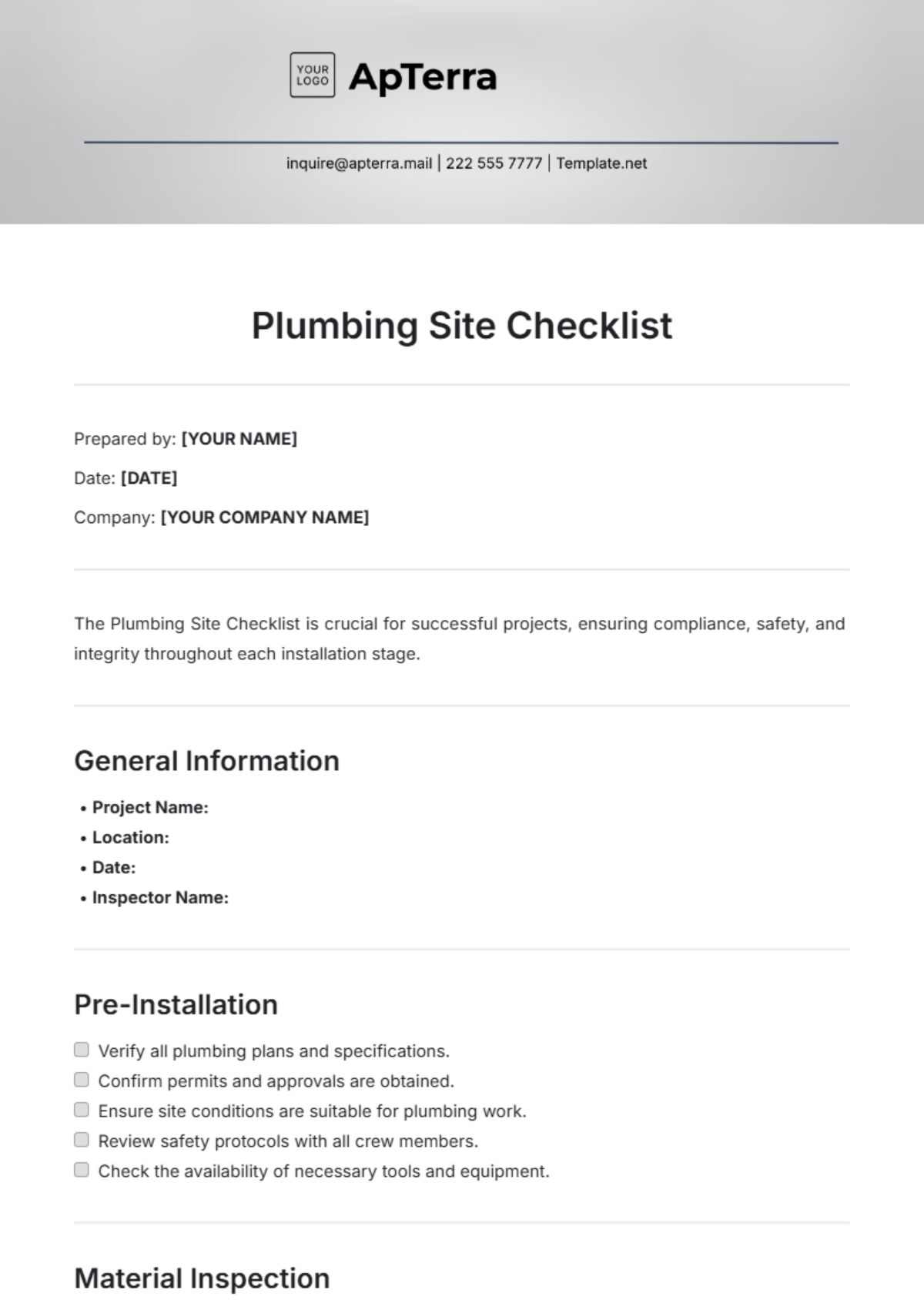

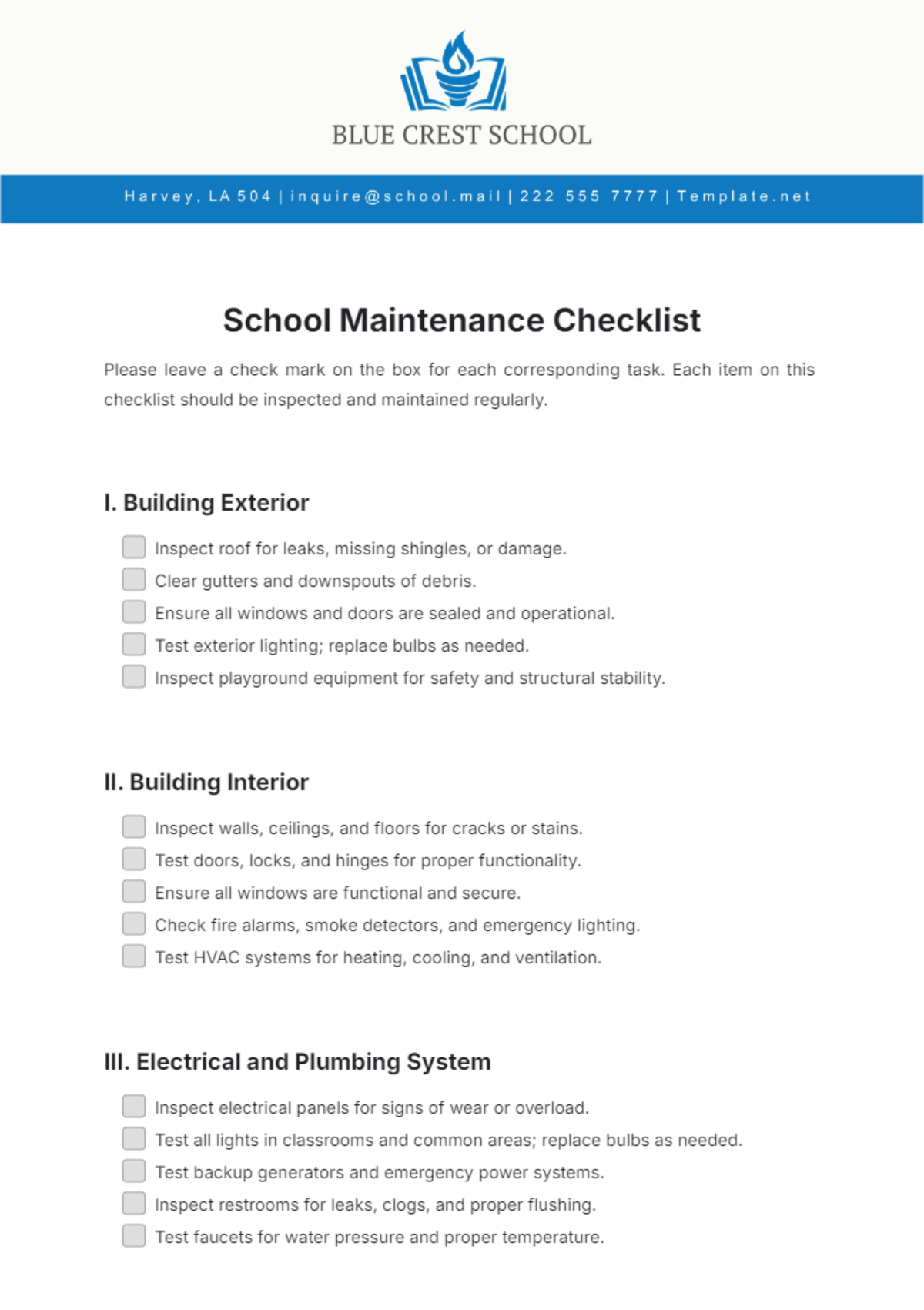

II. Maintenance Tasks

Task Description | Status | Comments |

|---|---|---|

Inspect belts for wear and tear. |

| |

Check lubrication levels and refill if necessary. |

| |

Test safety equipment for proper operation. |

| |

Clean sensors and ensure proper alignment. |

| |

Review operational logs and identify potential issues. |

| |

Calibrate speed settings for optimal performance. |

|

III. Frequency

Weekly

Monthly

Quarterly

Annually

IV. Responsible Personnel

Name: Nadette Ritchie

Role: Maintenance Technician

V. Completion Date

November 15, 2050

VI. Comments/Observations

The last inspection identified potential noise issues; monitoring is ongoing.

Training scheduled for new staff on proper equipment handling on November 12, 2050.

Ensure that all maintenance activities align with the new safety regulations implemented in 2051.

VII. Signatures

Nadette Ritchie

Maintenance Technician

[Your Name]

Supervisor

Additional Notes:

Safety Protocols: All personnel should be reminded to wear appropriate personal protective equipment (PPE) during maintenance tasks.

Upcoming Training: Schedule a refresher course on the operation and maintenance of conveyor systems for all technicians in early December 2050.

Future Upgrades: Consider evaluating the benefits of upgrading to an automated monitoring system for enhanced performance tracking by mid-2051.