Free Injury Report

Reported By: [Your Name]

Company: [Your Company Name]

1. Executive Summary

This report provides a comprehensive analysis of injuries sustained within the 2050 Construction Sector. It examines injury frequency, type, severity, trends, and potential causes. Additionally, preventive measures, risk factors, and recommendations are highlighted to mitigate future occurrences.

2. Background

In 2050, the construction sector will face unique injury risks due to rapid technological advances and high-density urban development. Understanding patterns, causes, and preventive strategies is essential for minimizing incident rates and ensuring a safe working environment. This report collates 2050 data from recent incidents to facilitate a systematic approach to injury management and prevention.

3. Injury Data Overview

3.1 Injury Frequency and Severity

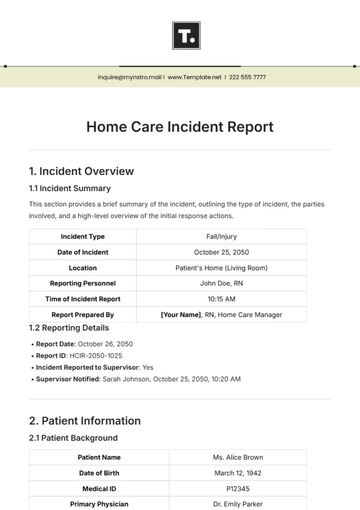

Injury Type | Number of Incidents | Severity Level (Mild/Moderate/Severe) | Percentage of Total Incidents |

|---|---|---|---|

Musculoskeletal | 50 | Moderate to Severe | 32% |

Cuts and Lacerations | 38 | Mild | 24% |

Sprains and Strains | 32 | Mild to Moderate | 21% |

Fractures | 16 | Severe | 11% |

Burns | 8 | Mild to Moderate | 5% |

Concussions | 6 | Severe | 4% |

Others | 4 | Varies | 3% |

Key Points:

Musculoskeletal injuries remain the most common, often severe, and associated with prolonged recovery times.

Cuts and lacerations, though frequent, tend to be less severe in impact.

Concussions, while less frequent, represent a significant risk in 2050 due to potential long-term effects associated with brain injuries.

3.2 Injury Location and Cause Analysis

Location | Primary Injury Type | Common Causes |

|---|---|---|

Smart Construction Sites | Fractures, Lacerations | Falls, robotic equipment mishandling |

Office Workstations | Sprains, Strains | Poor ergonomics, repetitive strain |

Automated Warehouses | Musculoskeletal, Strains | Lifting, posture, and autonomous equipment |

Manufacturing Facilities | Burns, Cuts | Chemical exposure, machinery accidents |

Sports Facilities | Concussions, Fractures | Physical contact, falls |

Analysis:

High-risk areas like smart construction sites and manufacturing facilities report more incidents, with serious outcomes.

Automated warehouses report higher rates of musculoskeletal injuries, suggesting a need for 2050 ergonomic assessments.

4. Injury Type Analysis

4.1 Musculoskeletal Injuries

Description: These injuries involve strains or sprains in muscles, tendons, and ligaments due to repetitive movements or improper lifting techniques common in 2050 workplaces.

Key Causes:

Heavy lifting without support

Poor posture

Repetitive motion without breaks

Prevention Recommendations:

Ergonomics training: Workshops on safe lifting and posture.

Adjustable workstations: Flexible options to alternate between sitting and standing.

4.2 Cuts and Lacerations

Description: These injuries are typically superficial but can become serious if deeper tissues are affected.

Key Causes:

Mishandling sharp tools or equipment

Lack of protective gloves

Prevention Recommendations:

Protective gear: Mandatory use of gloves and other protective equipment.

Equipment training: Training sessions on handling equipment with new 2050 technology.

4.3 Fractures

Description: Severe injuries often requiring extended recovery periods.

Key Causes:

Falls from elevated areas

Impacts with heavy machinery

Prevention Recommendations:

Safety protocols: Harnesses and guardrails on elevated workspaces.

Safety drills: Emphasis on situational awareness and hazard identification.

5. Trends and Patterns

5.1 Monthly Injury Trends

Month | Total Incidents | Severity Level (Average) |

|---|---|---|

January 2050 | 13 | Moderate |

February 2050 | 20 | Mild |

March 2050 | 24 | Severe |

April 2050 | 18 | Moderate |

May 2050 | 12 | Mild |

June 2050 | 22 | Moderate |

July 2050 | 19 | Severe |

August 2050 | 27 | Moderate |

September 2050 | 15 | Mild |

October 2050 | 20 | Moderate |

November 2050 | 17 | Severe |

December 2050 | 21 | Moderate |

Seasonal Insights:

Higher injury rates are noted in March, June, August, and December 2050.

A trend of severe injuries in colder months, likely influenced by environmental conditions and increased indoor construction activity.

5.2 Common Risk Factors

Environmental Conditions: Poor lighting, slippery floors, inadequate space.

Physical Strain: Heavy lifting, bending, and long hours in strenuous positions.

Lack of Updated Safety Training: Inadequate knowledge of 2050 safety protocols and handling of autonomous machinery.

6. Injury Management and Response

6.1 Immediate Response Protocols

First Aid:

On-site first aid if safe.

Stabilize injuries (especially fractures or head injuries).

Emergency Contacts:

Notify emergency medical services for severe injuries.

Immediate communication with the family of the injured employee.

Incident Documentation:

Record all incident details promptly, including time, location, cause, and severity.

6.2 Rehabilitation Programs

Description: Supportive measures for recovery and reintegration.

Key Components:

Physical Therapy: Essential for musculoskeletal injuries.

Ergonomics Assessments: Target strain prevention.

Counseling Services: Available for individuals who experienced severe injuries.

7. Preventive Measures and Recommendations

7.1 Training Programs

Injury Prevention Workshops: Focused on ergonomic awareness, safe lifting techniques, and injury awareness.

Safety Drills: Routine drills for high-risk areas focusing on 2050-specific hazards.

Certification Courses: Mandatory certifications for operating autonomous machinery.

7.2 Protective Equipment and Workplace Design

Personal Protective Equipment (PPE): Use of PPE like helmets, gloves, and advanced 2050 safety gear.

Smart Workplace Layouts: Designed to reduce collision risk and facilitate safe material handling.

7.3 Policy Recommendations

Enhanced Safety Policies:

Stricter guidelines on equipment usage.

Frequent safety inspections.

Incentive Programs:

Reward departments with excellent safety records.

Offer incentives for completing safety training.

8. Conclusion

This 2050 injury report identifies critical patterns and causes behind incidents within the construction sector. Emphasizing structured prevention and swift response protocols, the sector can reduce incidents and ensure a safer environment. By continuing to invest in robust training, safety protocols, and incident reviews, the 2050 workplace can become significantly safer.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

Template.net provides an Injury Report Template, designed to efficiently document injury details for workplace or personal incidents. This editable and customizable template allows you to input essential information in our AI Editor Tool for precise, standardized reporting. Perfect for keeping compliant records, the template ensures all necessary details are included, simplifying the documentation process and improving accuracy for future reference or analysis.

You may also like

- Sales Report

- Daily Report

- Project Report

- Business Report

- Weekly Report

- Incident Report

- Annual Report

- Report Layout

- Report Design

- Progress Report

- Marketing Report

- Company Report

- Monthly Report

- Audit Report

- Status Report

- School Report

- Reports Hr

- Management Report

- Project Status Report

- Handover Report

- Health And Safety Report

- Restaurant Report

- Construction Report

- Research Report

- Evaluation Report

- Investigation Report

- Employee Report

- Advertising Report

- Weekly Status Report

- Project Management Report

- Finance Report

- Service Report

- Technical Report

- Meeting Report

- Quarterly Report

- Inspection Report

- Medical Report

- Test Report

- Summary Report

- Inventory Report

- Valuation Report

- Operations Report

- Payroll Report

- Training Report

- Job Report

- Case Report

- Performance Report

- Board Report

- Internal Audit Report

- Student Report

- Monthly Management Report

- Small Business Report

- Accident Report

- Call Center Report

- Activity Report

- IT and Software Report

- Internship Report

- Visit Report

- Product Report

- Book Report

- Property Report

- Recruitment Report

- University Report

- Event Report

- SEO Report

- Conference Report

- Narrative Report

- Nursing Home Report

- Preschool Report

- Call Report

- Customer Report

- Employee Incident Report

- Accomplishment Report

- Social Media Report

- Work From Home Report

- Security Report

- Damage Report

- Quality Report

- Internal Report

- Nurse Report

- Real Estate Report

- Hotel Report

- Equipment Report

- Credit Report

- Field Report

- Non Profit Report

- Maintenance Report

- News Report

- Survey Report

- Executive Report

- Law Firm Report

- Advertising Agency Report

- Interior Design Report

- Travel Agency Report

- Stock Report

- Salon Report

- Bug Report

- Workplace Report

- Action Report

- Investor Report

- Cleaning Services Report

- Consulting Report

- Freelancer Report

- Site Visit Report

- Trip Report

- Classroom Observation Report

- Vehicle Report

- Final Report

- Software Report