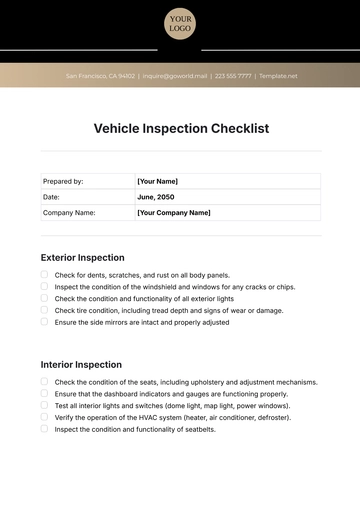

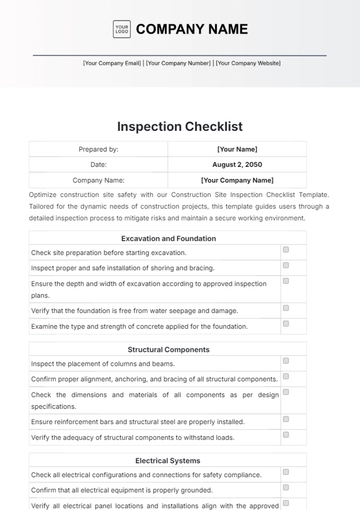

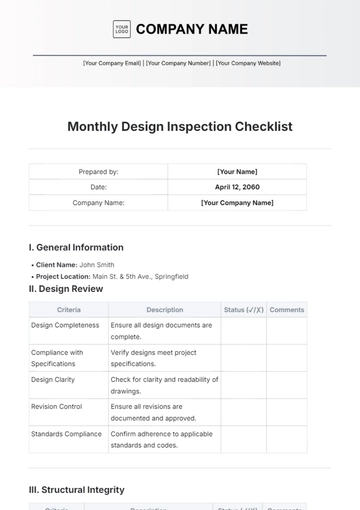

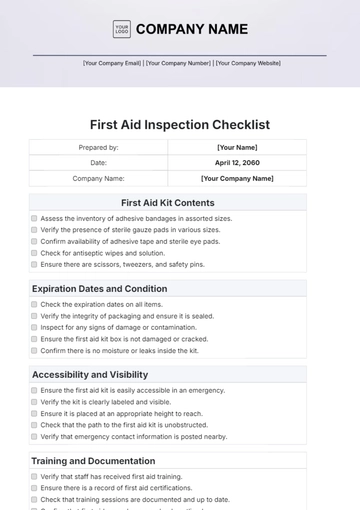

Free Aesthetic Brakes and Suspension Inspection Checklist

Prepared by:

[YOUR NAME]

[YOUR COMPANY NAME]

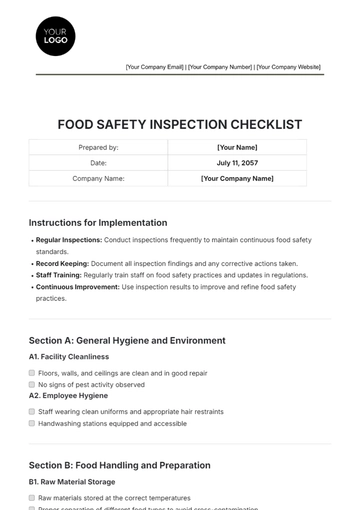

Brakes Inspection

1. Brake Pads and Shoes

Check for visible wear on brake pads or shoes.

Inspect for even wear patterns; check for grooves or uneven surfaces.

Examine for signs of excessive dust or debris buildup around the pads.

2. Brake Rotors/Discs

Visually inspect brake rotors for any signs of scoring, grooves, or cracks.

Check for rust buildup or discoloration.

Ensure the rotors are evenly mounted and free from excessive dirt or grease.

3. Brake Lines and Hoses

Look for any visible signs of leakage or fluid stains.

Inspect the brake lines and hoses for cracks, bulges, or signs of wear.

Ensure hoses are securely fastened and not rubbing against other parts.

4. Brake Calipers

Check for visible damage or leakage around the caliper pistons.

Inspect the condition of the paint or finish for any signs of rust, corrosion, or chipping.

Ensure calipers are evenly mounted and functioning properly.

5. Brake Fluid Reservoir

Visually inspect the brake fluid reservoir for proper fluid levels.

Check for any signs of leakage around the reservoir cap or housing.

Ensure the reservoir is clean, free from dirt, and properly sealed.

Suspension Inspection

1. Shock Absorbers

Check for visible damage, such as cracks, dents, or oil leakage.

Inspect the condition of the shock absorber mounts for signs of wear or loosening.

Ensure the absorbers are free from rust and other corrosion-related issues.

2. Springs

Look for any broken, cracked, or misaligned springs.

Check for rust or corrosion, especially around the spring coils.

Inspect for signs of excessive wear on spring mounts.

3. Control Arms and Bushings

Inspect control arms for signs of bending, wear, or corrosion.

Check bushings for cracks or splitting that could affect suspension performance.

Ensure all control arm mounts are secure and free from rust.

4. Ball Joints and Tie Rods

Visually inspect ball joints for any signs of wear or damage.

Check tie rods for signs of corrosion or bending.

Ensure that all joints are properly lubricated and functioning smoothly.

5. Suspension Mounting Points

Check suspension mounts for any signs of rust, corrosion, or cracking.

Ensure all bolts, nuts, and fasteners are properly tightened.

Inspect for any signs of excessive wear or damage around mounting points.

6. Wheel Alignment and Tension

Check for uneven tire wear, which may indicate misalignment.

Inspect suspension components for damage that could affect alignment.

Ensure suspension components are properly tensioned to prevent instability.

- 100% Customizable, free editor

- Access 1 Million+ Templates, photo’s & graphics

- Download or share as a template

- Click and replace photos, graphics, text, backgrounds

- Resize, crop, AI write & more

- Access advanced editor

The Aesthetic Brakes and Suspension Inspection Checklist Template from Template.net is an editable and customizable tool designed for detailed vehicle assessments. Easily modify the checklist to fit your specific needs using our AI Editor Tool. This template ensures thorough inspections of brakes and suspension systems, promoting safety and performance in every vehicle check.

You may also like

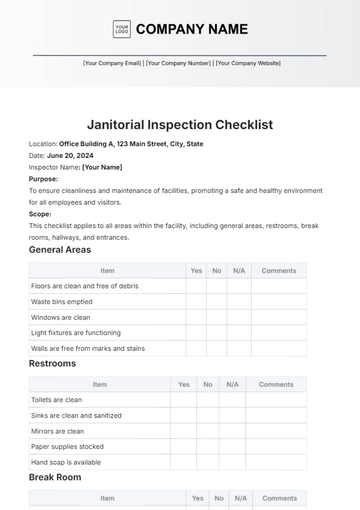

- Cleaning Checklist

- Daily Checklist

- Travel Checklist

- Self Care Checklist

- Risk Assessment Checklist

- Onboarding Checklist

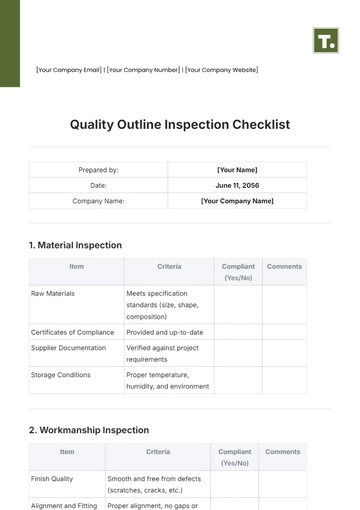

- Quality Checklist

- Compliance Checklist

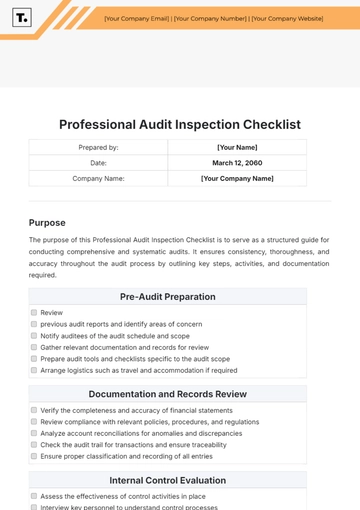

- Audit Checklist

- Registry Checklist

- HR Checklist

- Restaurant Checklist

- Checklist Layout

- Creative Checklist

- Sales Checklist

- Construction Checklist

- Task Checklist

- Professional Checklist

- Hotel Checklist

- Employee Checklist

- Moving Checklist

- Marketing Checklist

- Accounting Checklist

- Camping Checklist

- Packing Checklist

- Real Estate Checklist

- Cleaning Checklist Service

- New Employee Checklist

- Food Checklist

- Home Inspection Checklist

- Advertising Checklist

- Event Checklist

- SEO Checklist

- Assessment Checklist

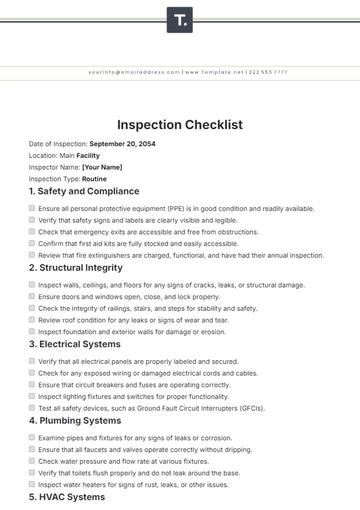

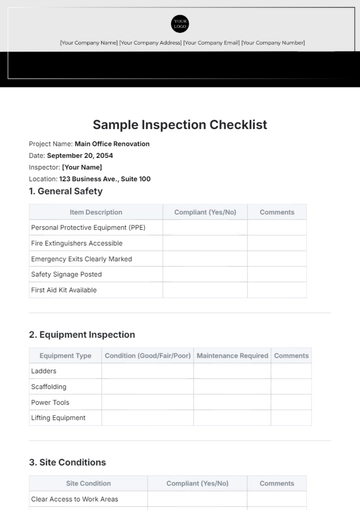

- Inspection Checklist

- Baby Registry Checklist

- Induction Checklist

- Employee Training Checklist

- Medical Checklist

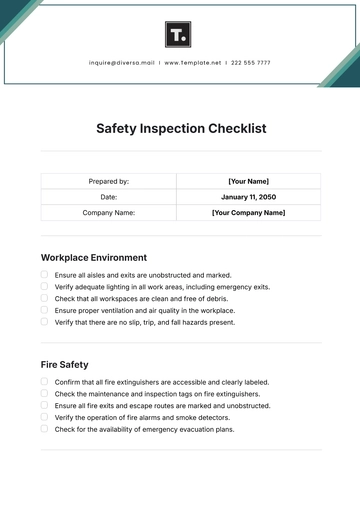

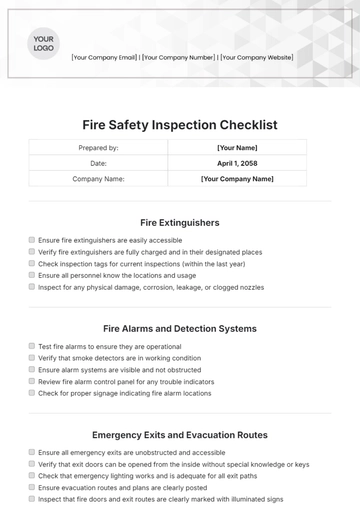

- Safety Checklist

- Site Checklist

- Job Checklist

- Service Checklist

- Nanny Checklist

- Building Checklist

- Work Checklist

- Office Checklist

- Training Checklist

- Website Checklist

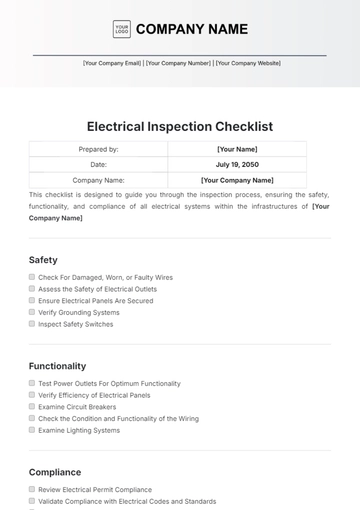

- IT and Software Checklist

- Performance Checklist

- Project Checklist

- Startup Checklist

- Education Checklist

- Home Checklist

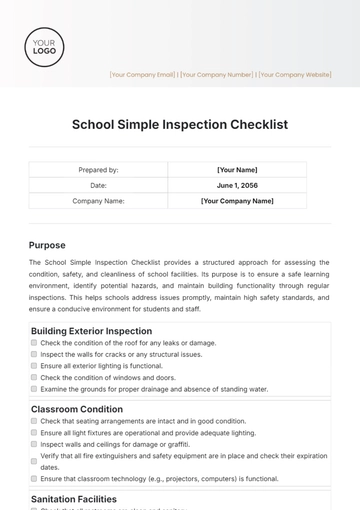

- School Checklist

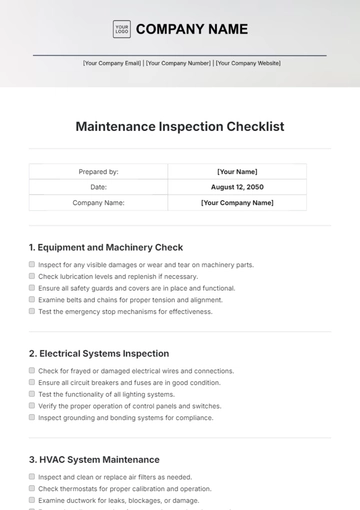

- Maintenance Checklist

- Planning Checklist

- Manager Checklist

- Wedding Checklist

- Vehicle Checklist

- Travel Agency Checklist

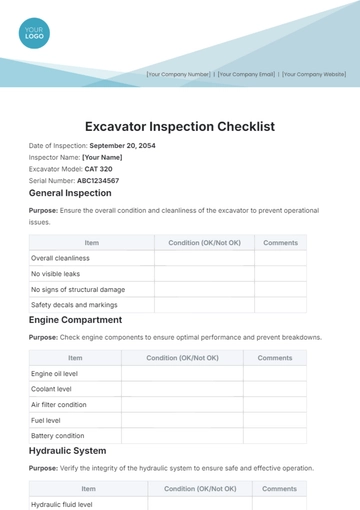

- Vehicle Inspection Checklist

- Interior Design Checklist

- Backpacking Checklist

- Business Checklist

- Legal Checklist

- Nursing Home Checklist

- Weekly Checklist

- Recruitment Checklist

- Salon Checklist

- Baby Checklist

- Equipment Checklist

- Trade Show Checklist

- Party Checklist

- Hospital Bag Checklist

- Evaluation Checklist

- Agency Checklist

- First Apartment Checklist

- Hiring Checklist

- Opening Checklist

- Small Business Checklist

- Rental Checklist

- College Dorm Checklist

- New Puppy Checklist

- University Checklist

- Building Maintenance Checklist

- Work From Home Checklist

- Student Checklist

- Application Checklist