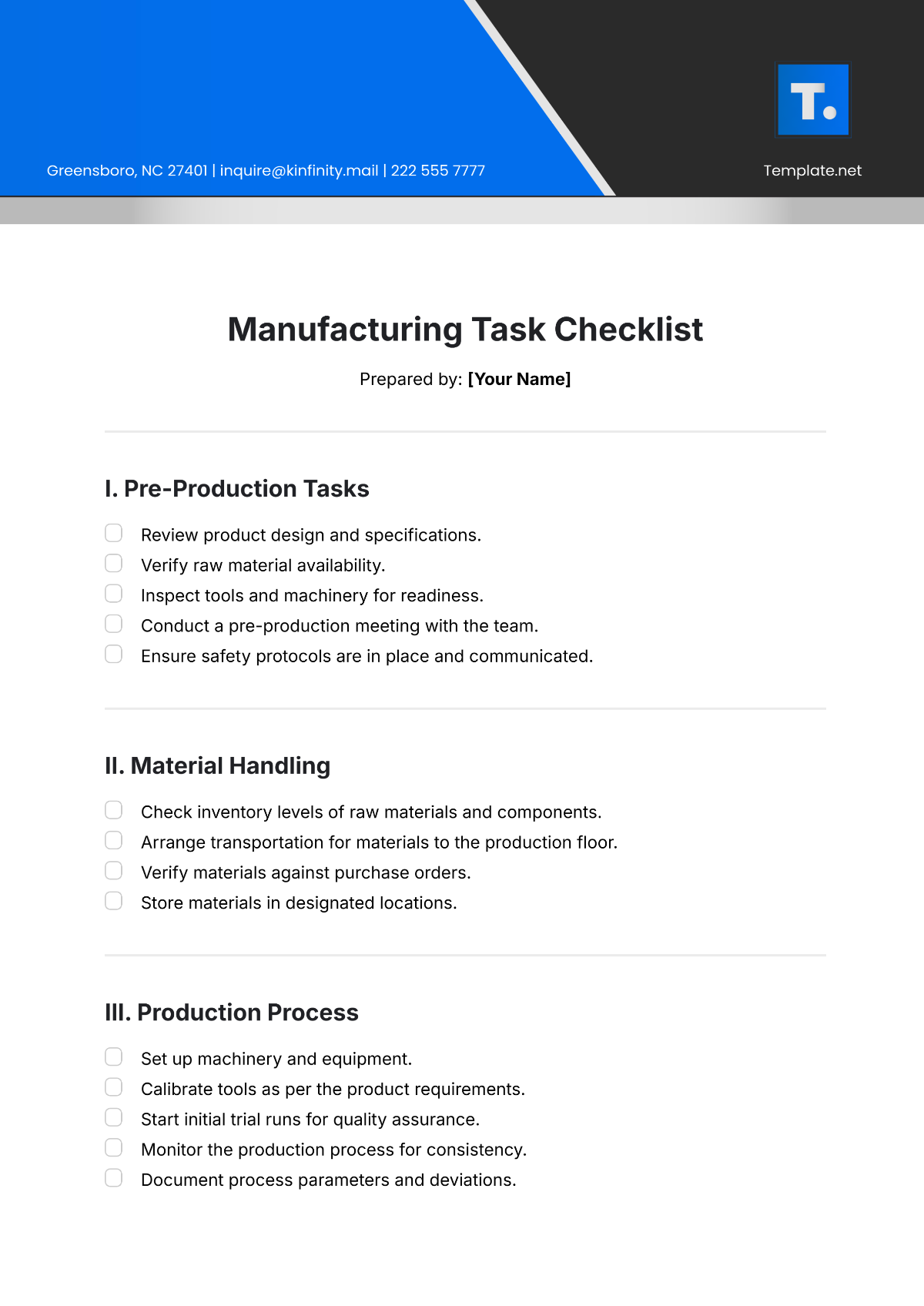

Manufacturing Task Checklist

Prepared by: [Your Name]

I. Pre-Production Tasks

Review product design and specifications.

Verify raw material availability.

Inspect tools and machinery for readiness.

Conduct a pre-production meeting with the team.

Ensure safety protocols are in place and communicated.

II. Material Handling

Check inventory levels of raw materials and components.

Arrange transportation for materials to the production floor.

Verify materials against purchase orders.

Store materials in designated locations.

III. Production Process

Set up machinery and equipment.

Calibrate tools as per the product requirements.

Start initial trial runs for quality assurance.

Monitor the production process for consistency.

Document process parameters and deviations.

IV. Quality Control

Inspect raw materials for defects.

Conduct in-process quality checks at defined intervals.

Test finished products for compliance with standards.

Document quality inspection results.

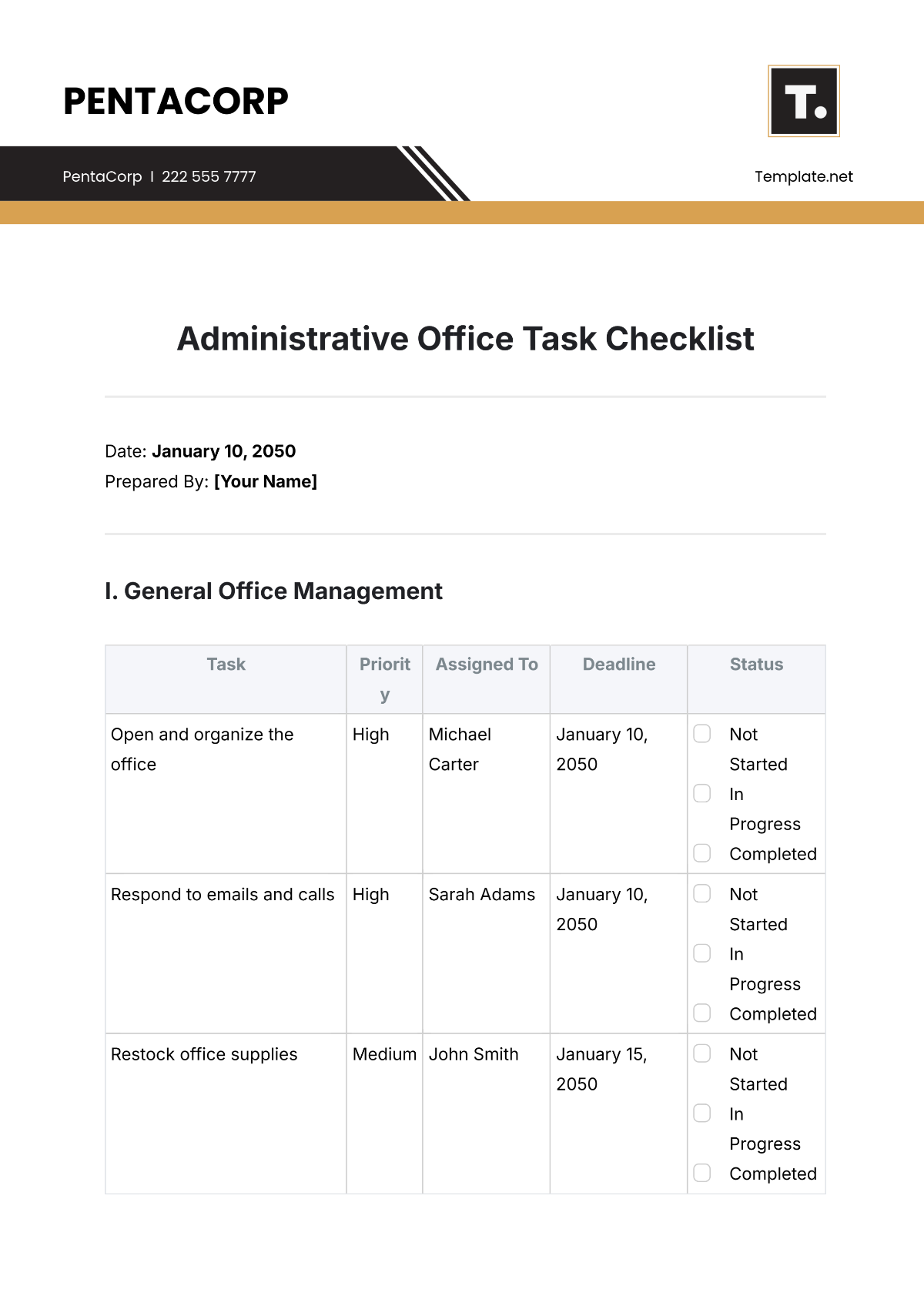

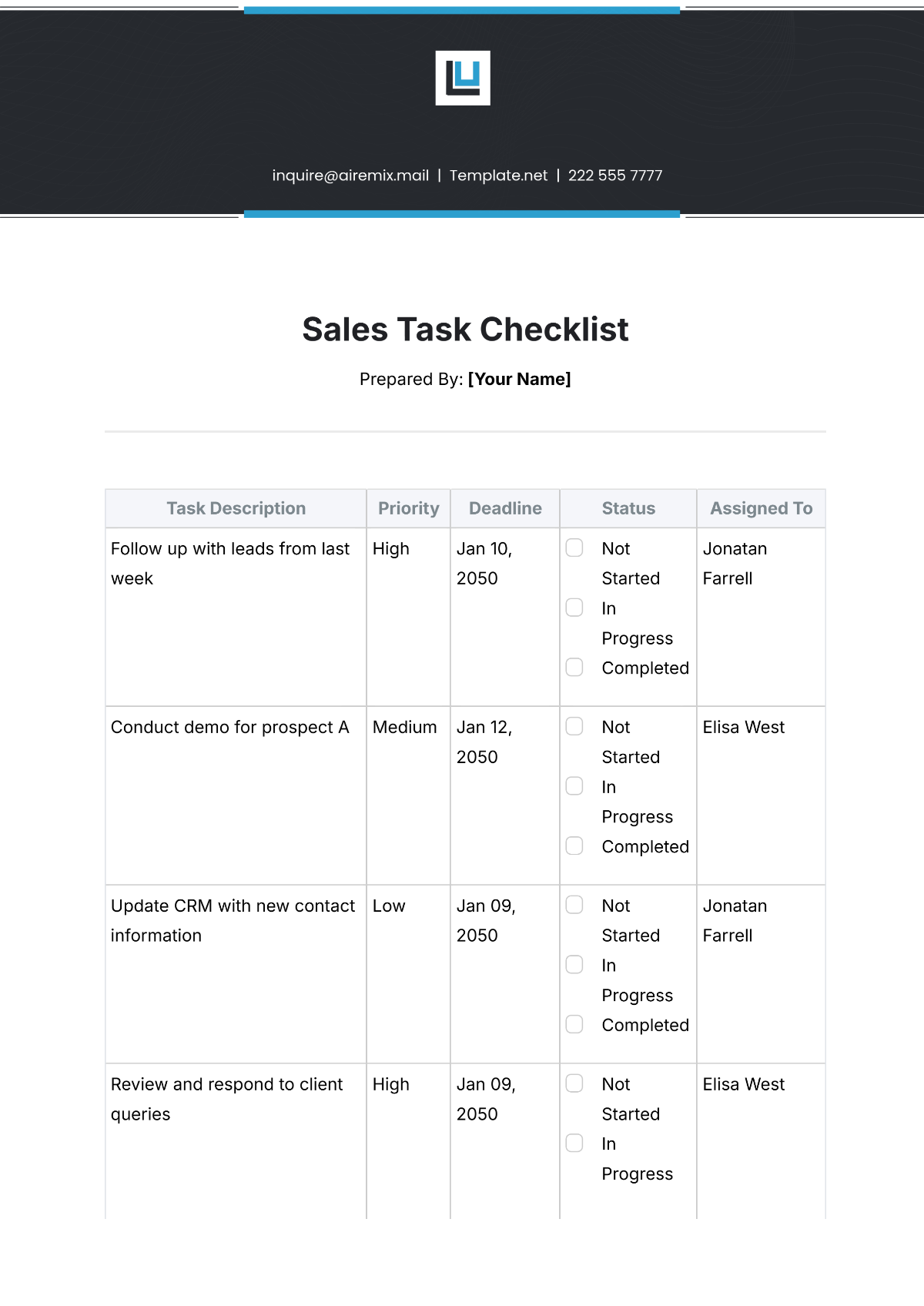

V. Workforce Management

Assign tasks and responsibilities to team members.

Ensure adequate workforce availability.

Conduct safety briefings for shifts.

Address any worker concerns during operations.

VI. Maintenance and Troubleshooting

Perform routine maintenance checks on equipment.

Resolve any mechanical or technical issues promptly.

Record maintenance activities in logs.

VII. Post-Production Tasks

Inspect finished goods for packaging readiness.

Package products according to specifications.

Label and document packaged items.

Arrange for storage or shipment of finished goods.

VIII. Documentation and Reporting

Update production logs with relevant data.

Prepare daily or weekly production reports.

Report any incidents or deviations to management.

Archive production records securely.

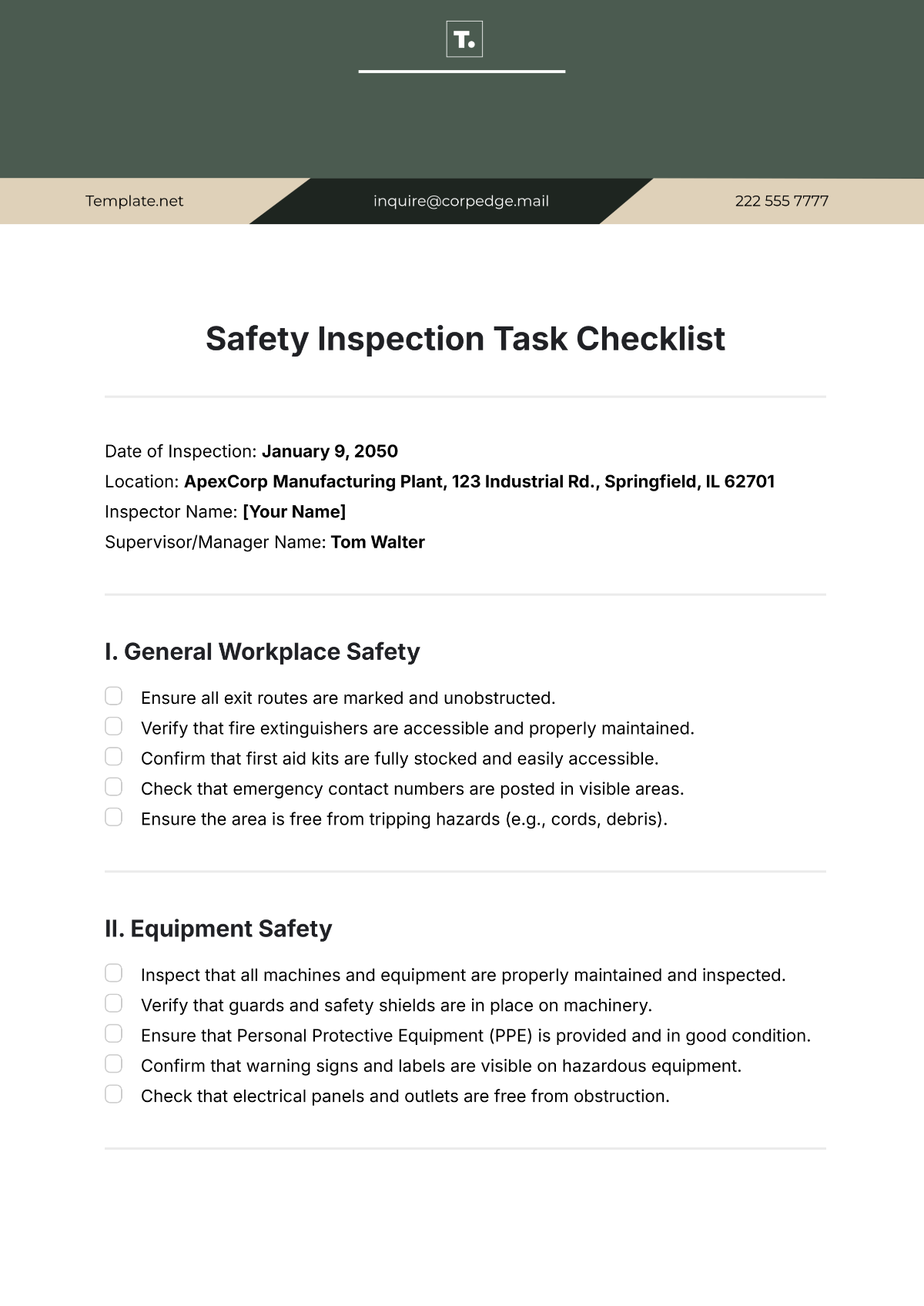

IX. Safety and Compliance

Ensure adherence to health and safety standards.

Verify compliance with regulatory requirements.

Conduct post-production safety checks.

X. Continuous Improvement

Gather feedback from team members.

Analyze production metrics for efficiency improvements.

Identify areas for process optimization.

Schedule follow-up meetings for improvement discussions.