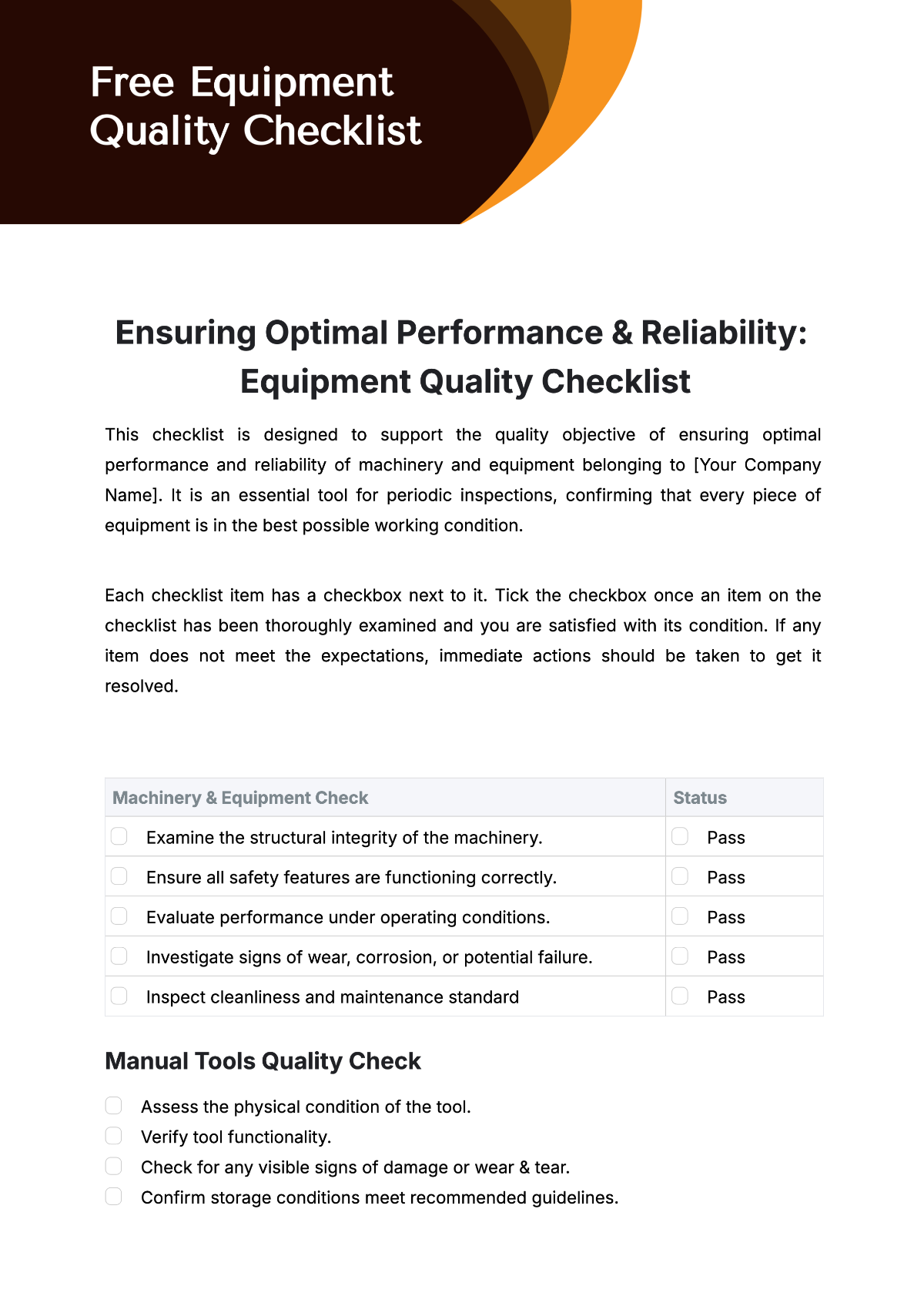

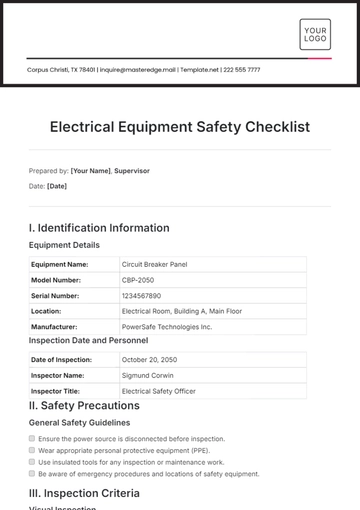

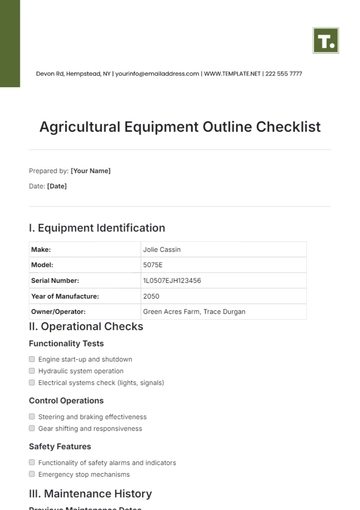

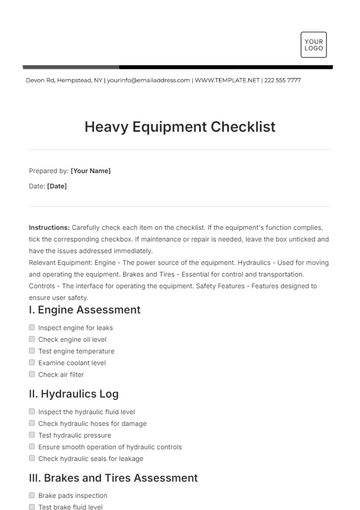

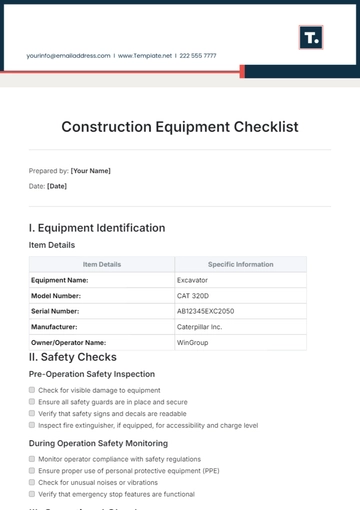

Ensuring Optimal Performance & Reliability: Equipment Quality Checklist

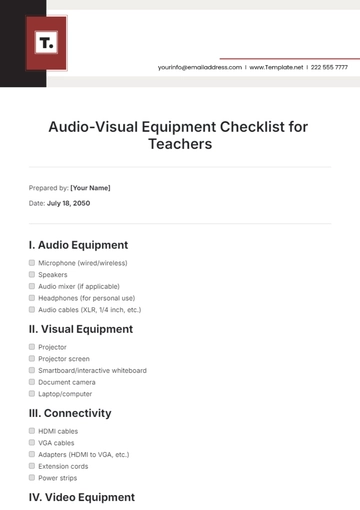

This checklist is designed to support the quality objective of ensuring optimal performance and reliability of machinery and equipment belonging to [Your Company Name]. It is an essential tool for periodic inspections, confirming that every piece of equipment is in the best possible working condition.

Each checklist item has a checkbox next to it. Tick the checkbox once an item on the checklist has been thoroughly examined and you are satisfied with its condition. If any item does not meet the expectations, immediate actions should be taken to get it resolved.

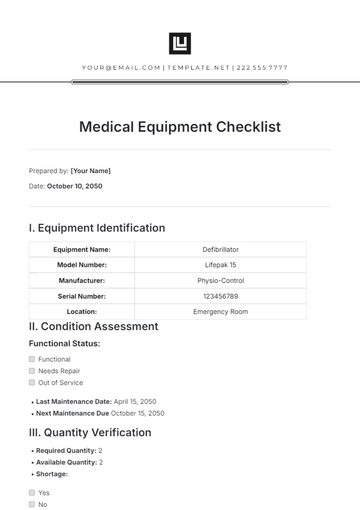

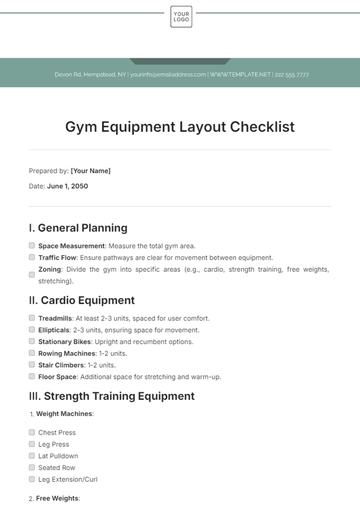

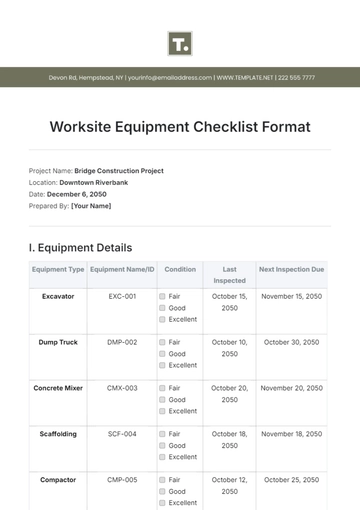

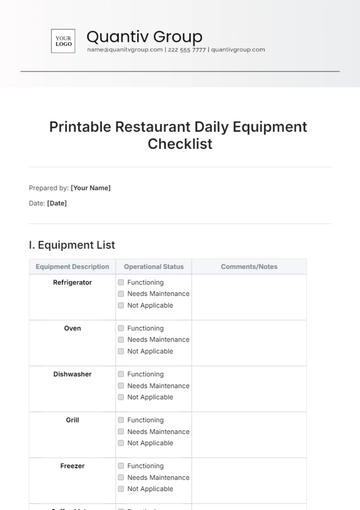

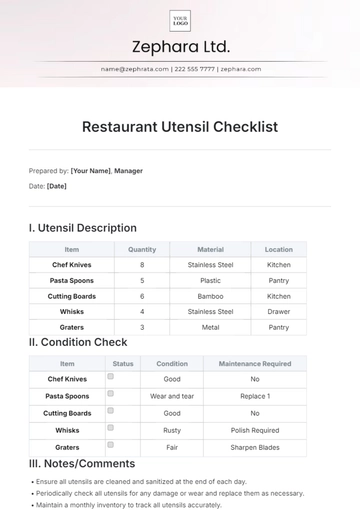

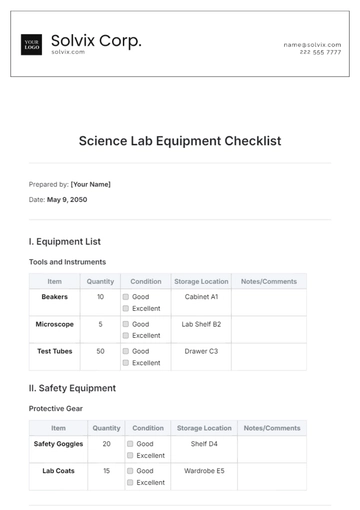

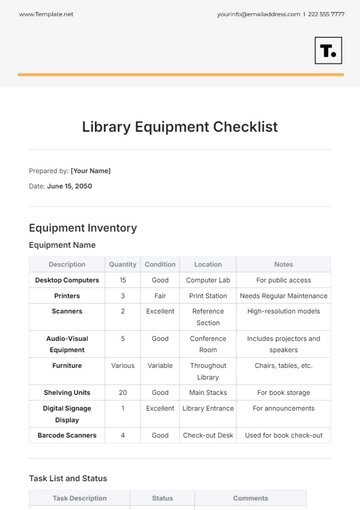

Machinery & Equipment Check | Status |

|---|

| |

| |

| |

| |

| |

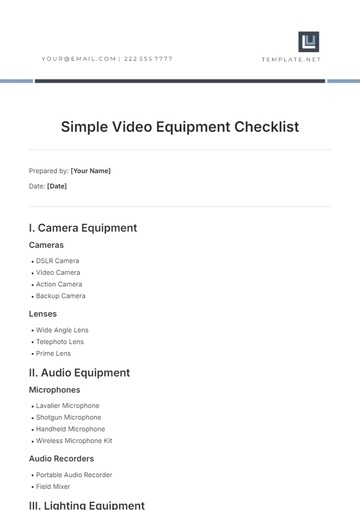

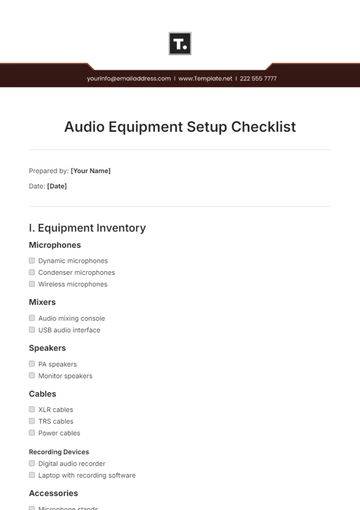

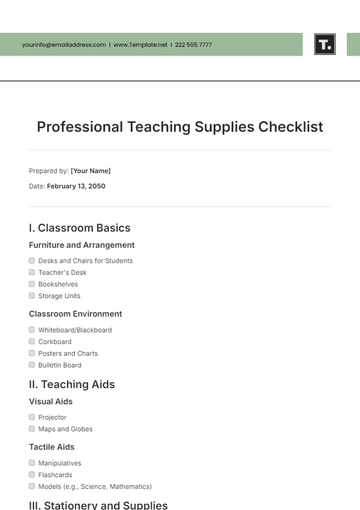

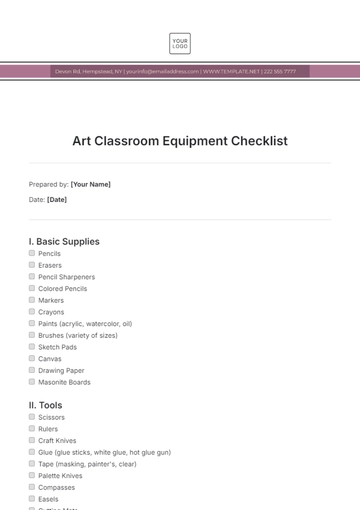

Manual Tools Quality Check

All machines and tools should be thoroughly inspected using this checklist to detect and resolve any potential issues and guarantee optimal functionality and performance.

Reminder: Always prioritize safety when inspecting the equipment. Always follow the equipment safety procedure during an inspection. If you come across any faulty equipment, report it immediately and do not use it until it is repaired.

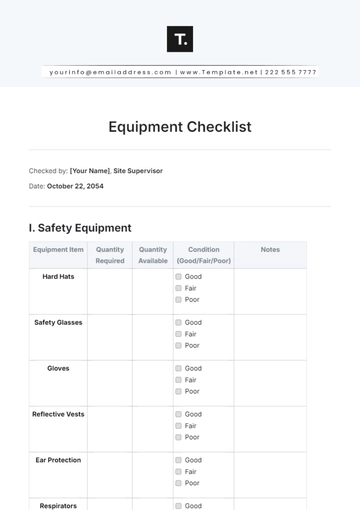

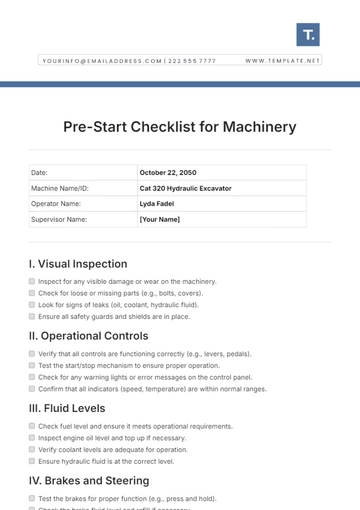

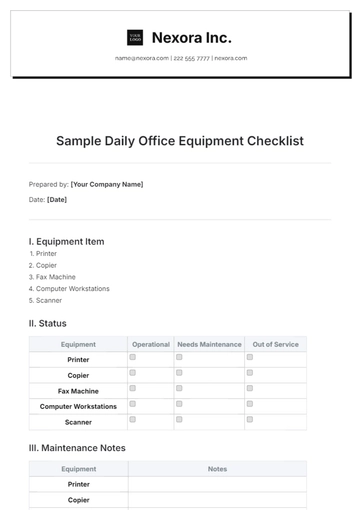

Checklist Templates @ Template.net