Electronics Assembly Budget Justification

I. Introduction

This document provides a comprehensive budget justification for the costs associated with assembling electronic components and systems at [Your Company Name]. It aims to ensure transparency and accountability in the budget, promoting a clear understanding among stakeholders and streamlining the approval process. The following sections detail the financial requirements and offer a rationale for each expense.

II. Cost Breakdown

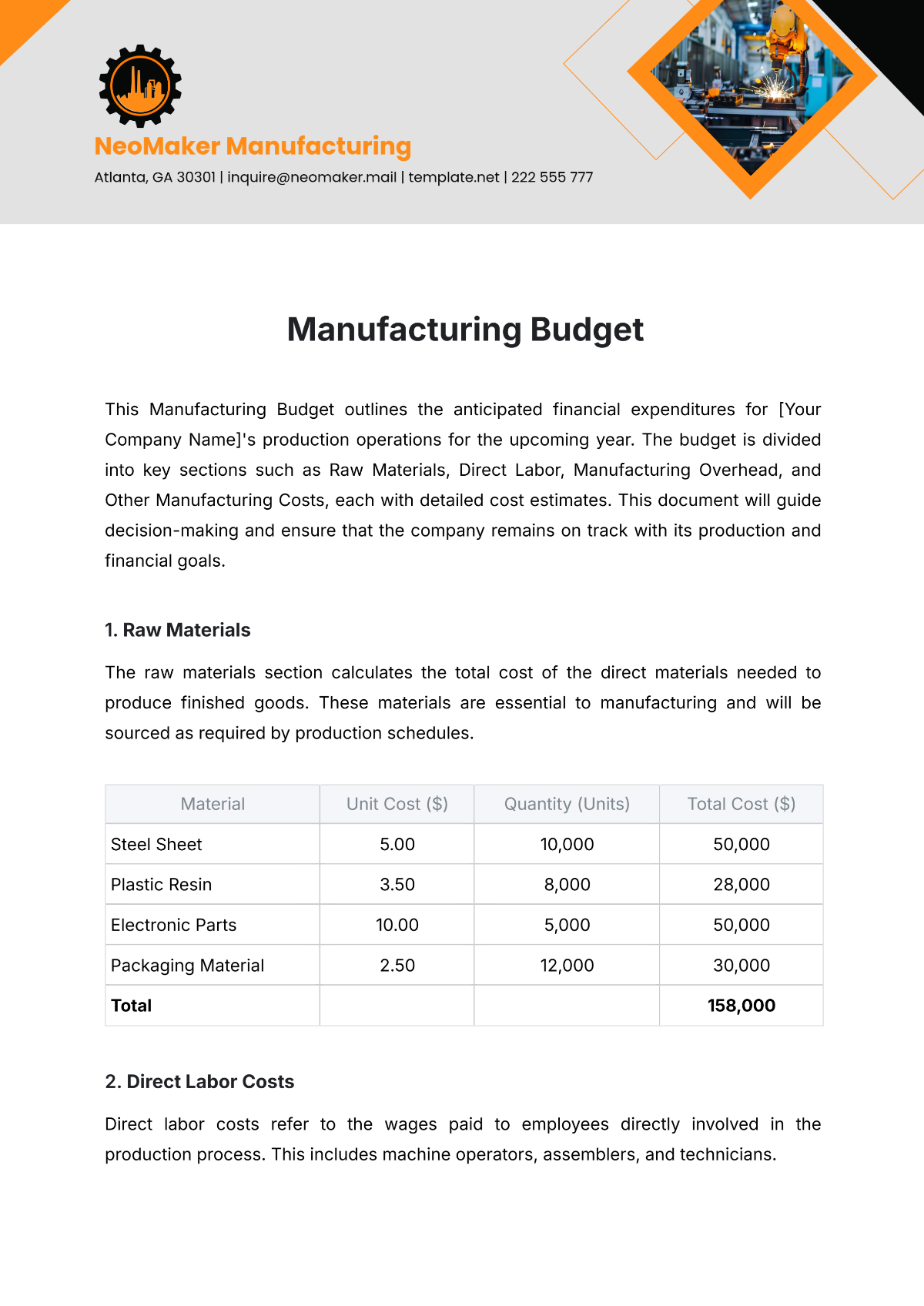

Material Costs

Material costs represent the fundamental expenses associated with acquiring the necessary components for assembly. These expenses include, but are not limited to:

Integrated Circuits (ICs)

Resistors, Capacitors, Inductors

Printed Circuit Boards (PCBs)

Connectors and Wiring

Enclosures and Cases

Component | Description | Unit Cost ($) | Quantity | Total Cost ($) |

|---|---|---|---|---|

Integrated Circuits | Various types of ICs | 2.00 | 500 | 1000.00 |

Resistors | Assorted values | 0.05 | 2000 | 100.00 |

Capacitors | Assorted values | 0.10 | 2000 | 200.00 |

PCBs | Custom designed | 10.00 | 200 | 2000.00 |

Enclosures | Custom built | 15.00 | 200 | 3000.00 |

Total Material Cost: $6,300.00

Labor Costs

Labor costs are incurred by the personnel involved in the assembly, quality assurance, and testing of the electronic components and systems. Key roles include:

Engineers

Technicians

Quality Assurance Specialists

Role | Description | Hourly Rate ($) | Hours | Total Cost ($) |

|---|---|---|---|---|

Engineer | Circuit design & system integration | 40.00 | 400 | 16000.00 |

Technician | Assembly & testing | 25.00 | 500 | 12500.00 |

Quality Assurance Specialist | Inspections & validation | 30.00 | 200 | 6000.00 |

Total Labor Cost: $34,500.00

Overhead Costs

Overhead costs include expenses that are not directly tied to the production but are essential for overall project execution. These include:

Utilities (electricity, water, etc.)

Equipment depreciation

Administrative expenses

Category | Description | Monthly Cost ($) | Duration (Months) | Total Cost ($) |

|---|---|---|---|---|

Utilities | Electricity, water, etc. | 500.00 | 6 | 3000.00 |

Equipment Depreciation | Wear and tear | 400.00 | 6 | 2400.00 |

Administrative Expenses | Office, supplies | 300.00 | 6 | 1800.00 |

Total Overhead Cost: $7,200.00

III. Additional Costs

Testing and Validation

This section covers costs associated with thorough testing and validation of the assembled components and systems to ensure they meet required specifications and standards.

Item | Description | Unit Cost ($) | Quantity | Total Cost ($) |

|---|---|---|---|---|

Test Equipment | Specialized testing tools | 1,000.00 | 1 | 1,000.00 |

Validation Services | External validation services | 2,500.00 | 1 | 2,500.00 |

Total Testing and Validation Cost: $3,500.00

Training Costs

Training costs are associated with educating personnel on new systems, technologies, or procedures necessary for the assembly and quality assurance process.

Item | Description | Unit Cost ($) | Quantity | Total Cost ($) |

|---|---|---|---|---|

Training Programs | Technical training sessions | 500.00 | 5 | 2,500.00 |

Training Materials | Manuals and instructional materials | 200.00 | 10 | 2,000.00 |

Total Training Cost: $4,500.00

IV. Total Budget Summary

Category | Total Cost ($) |

|---|---|

Material Costs | 6,300.00 |

Labor Costs | 34,500.00 |

Overhead Costs | 7,200.00 |

Testing and Validation Costs | 3,500.00 |

Training Costs | 4,500.00 |

Total Budget Required: $56,000.00

V. Justification

Each expense item listed above is crucial for the successful assembly and deployment of the electronic components and systems. The material costs ensure that we have all the necessary parts required for construction. Labor costs cover the expertise required for design, assembly, and quality assurance. Overhead costs account for the essential running expenses of the project, contributing to a stable working environment and maintaining optimum operational efficiency.

By investing in these critical areas, we are ensuring the high quality and reliability of the final product, which in turn, minimizes the risk of failures and enhances stakeholder satisfaction.

VI. Conclusion

This budget justification document aims to provide a transparent and accountable overview of the financial requirements necessary for assembling electronic components and systems. The detailed breakdown and rationale for each cost category illustrate the essential nature of these expenses, thereby facilitating informed decision-making by stakeholders.

Approval of this budget will allow us to proceed with confidence, knowing that we have the necessary resources to achieve our project goals successfully.