Automation Systems Budget Justification

I. Introduction

The purpose of this document is to provide a detailed budget justification for the implementation or upgrading of automation systems for [Your Company Name]. This initiative is critical to enhancing operational efficiency, reducing labor costs, and improving overall productivity. The budget justification outlines all costs, including equipment, software, labor, and maintenance, and provides a rationale for each expenditure to ensure alignment with project goals and organizational needs.

II. Project Objectives

The primary objectives of this project are:

To increase operational efficiency by reducing manual intervention.

To achieve higher accuracy and reliability in processes through automation.

To minimize labor costs and reallocate resources to strategic areas.

To enhance data collection and reporting for better decision-making.

III. Cost Breakdown

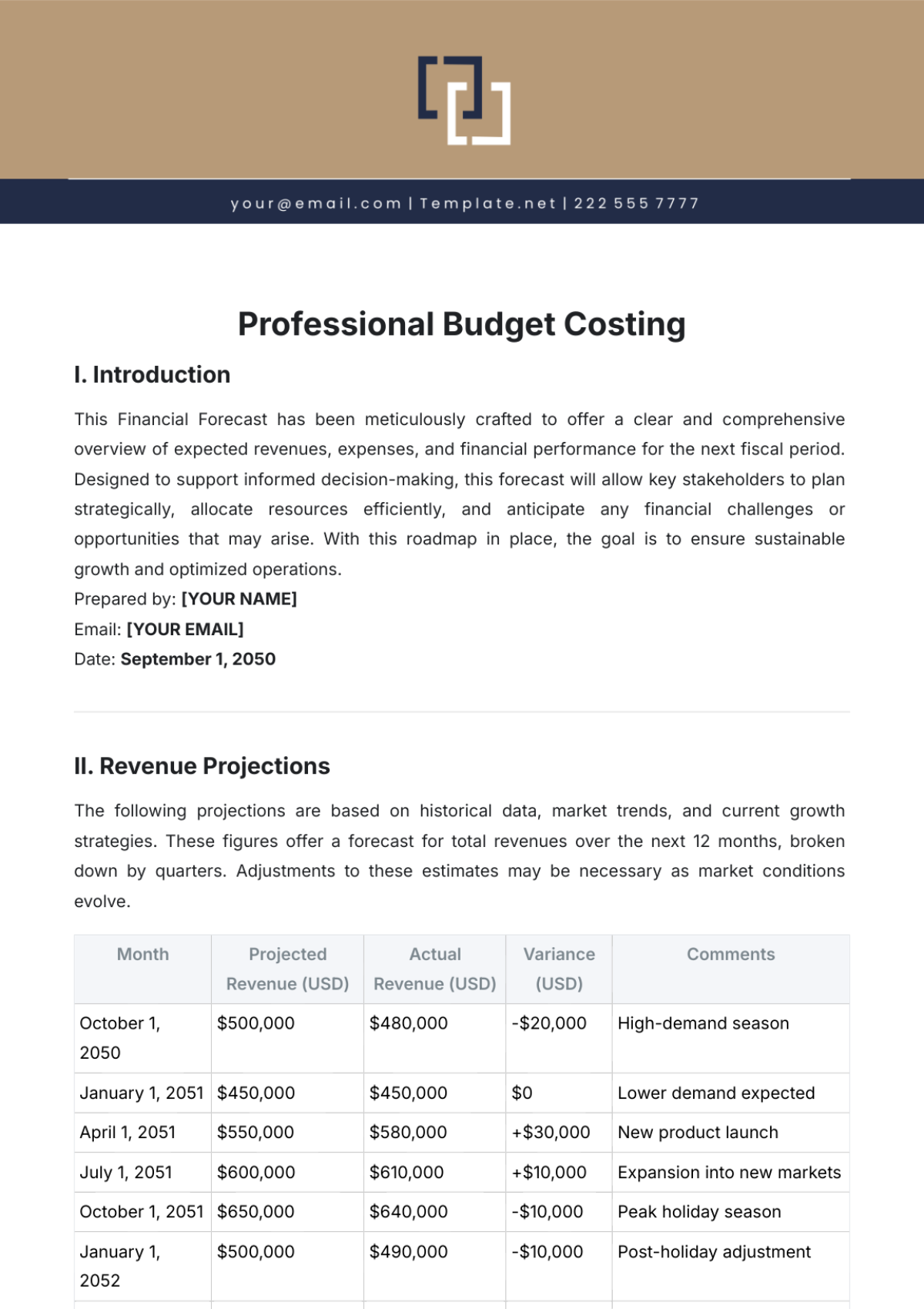

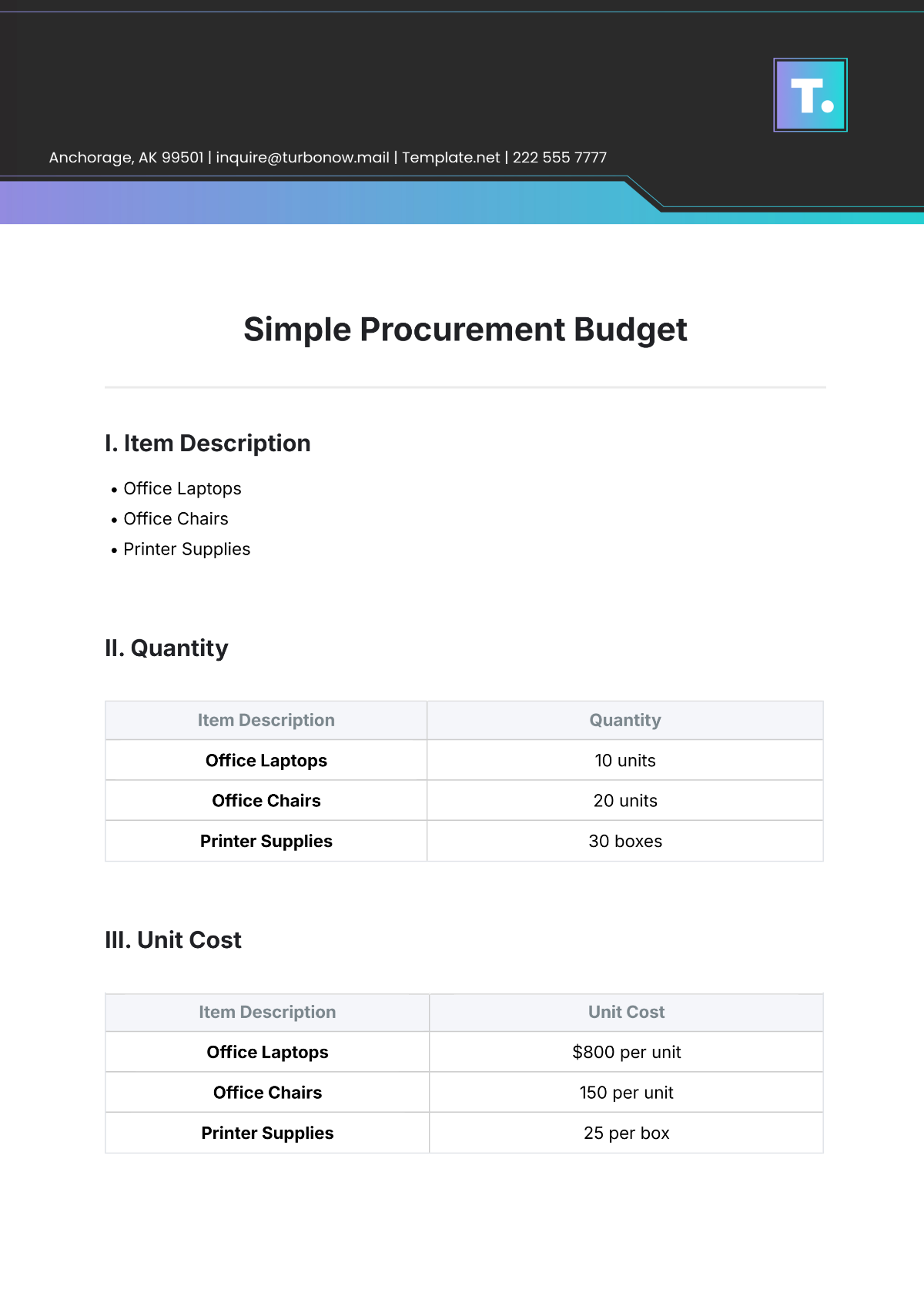

Equipment

The following table provides a detailed breakdown of the equipment costs:

Item | Quantity | Unit Cost | Total Cost |

|---|---|---|---|

Automated Production Machines | 5 | $10,000 | $50,000 |

Sensors and Actuators | 50 | $200 | $10,000 |

Robotic Arms | 3 | $15,000 | $45,000 |

Total Equipment Cost: $105,000

Software

The following table outlines the costs for the necessary software:

Software | Licenses | Unit Cost | Total Cost |

|---|---|---|---|

Automation Control Software | 10 | $1,000 | $10,000 |

Data Analytics Tool | 5 | $2,000 | $10,000 |

System Monitoring Software | 10 | $500 | $5,000 |

Total Software Cost: $25,000

Labor

The labor costs include both internal and external resources required for the implementation and training:

Internal Labor Costs:

Position | Hours | Hourly Rate | Total Cost |

|---|---|---|---|

Project Manager | 200 | $50 | $10,000 |

Engineers | 400 | $40 | $16,000 |

Total Internal Labor Cost: $26,000

External Consultant Costs:

Position | Hours | Hourly Rate | Total Cost |

|---|---|---|---|

External Consultant | 100 | $100 | $10,000 |

Total External Labor Cost: $10,000

Total Labor Cost: $36,000

Maintenance

Maintenance costs include the following anticipated expenses:

Annual Maintenance of Equipment: $10,000

Software Subscription and Updates: $5,000

Spare Parts and Repairs: $5,000

Total Maintenance Cost: $20,000

IV. Total Budget

Cost Component | Amount |

|---|---|

Total Equipment Cost | $105,000 |

Total Software Cost | $25,000 |

Total Labor Cost | $36,000 |

Total Maintenance Cost | $20,000 |

Total Anticipated Cost: $186,000

V. Rationale for Expenditures

The expenditures outlined in this budget justification are essential for the successful implementation and upgrading of our automation systems. The primary benefits associated with these investments include:

Significantly reduced manual labor and associated costs.

Improved accuracy and efficiency in production processes.

Enhanced capability to collect and analyze data for informed decision-making.

Reduction in downtime and increased operational uptime through predictive maintenance capabilities.

VI. Conclusion

In conclusion, the implementation and upgrading of automation systems require a comprehensive budget that covers equipment, software, labor, and maintenance. The total anticipated cost for this project is $186,000. These investments are critical for achieving our strategic objectives and maintaining a competitive edge in the industry. Your approval of this budget is requested to ensure the timely and successful execution of this project.